Welding electrode coating removing device

A technology for welding electrodes and coatings, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of damp electrodes, paint corrosion, pores or high content of diffused hydrogen, and achieve the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

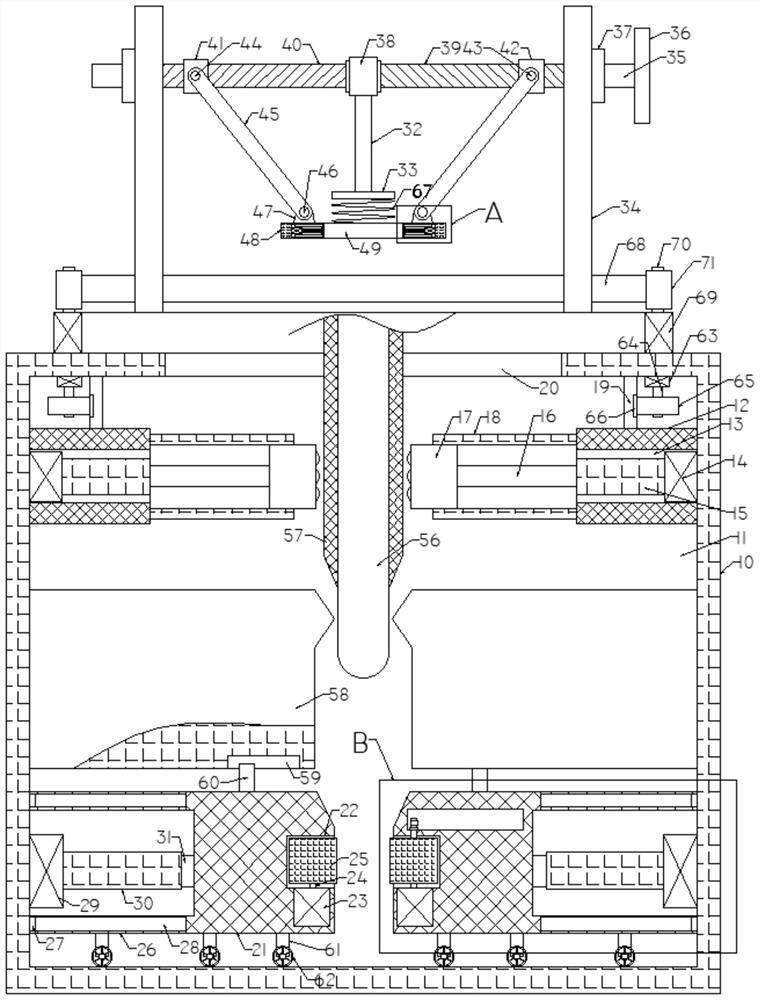

[0019] Bonded below Figure 1-3 The present invention will be described in detail, in which it is convenient for the description, the orientation of the following statement is as follows: The above-mentioned left and right directions figure 1 The projection relationship of the projection is consistent with the front and back and so on.

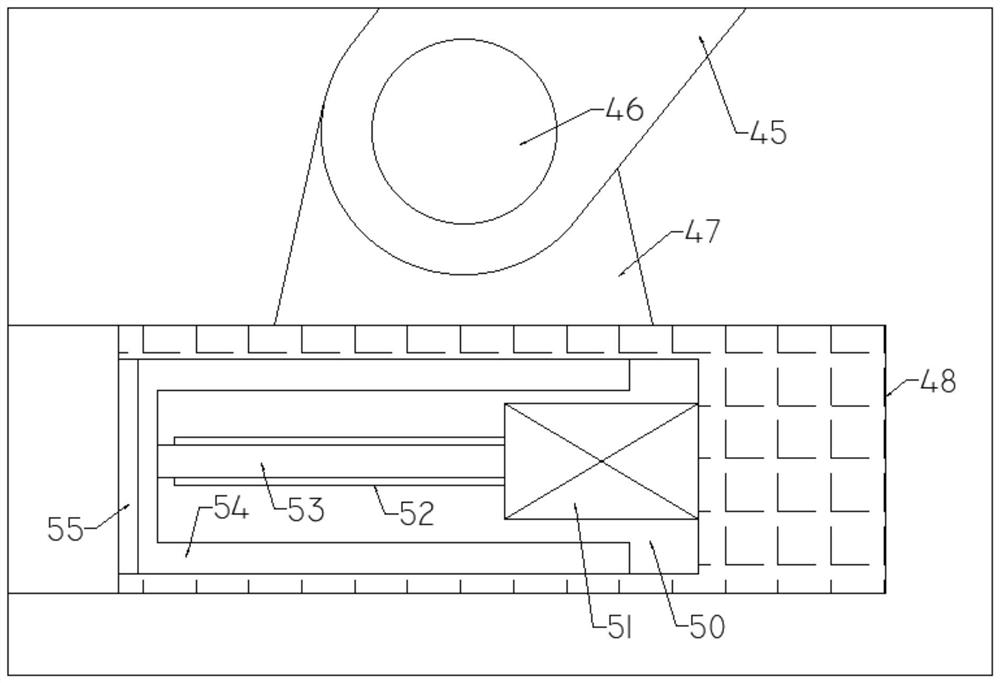

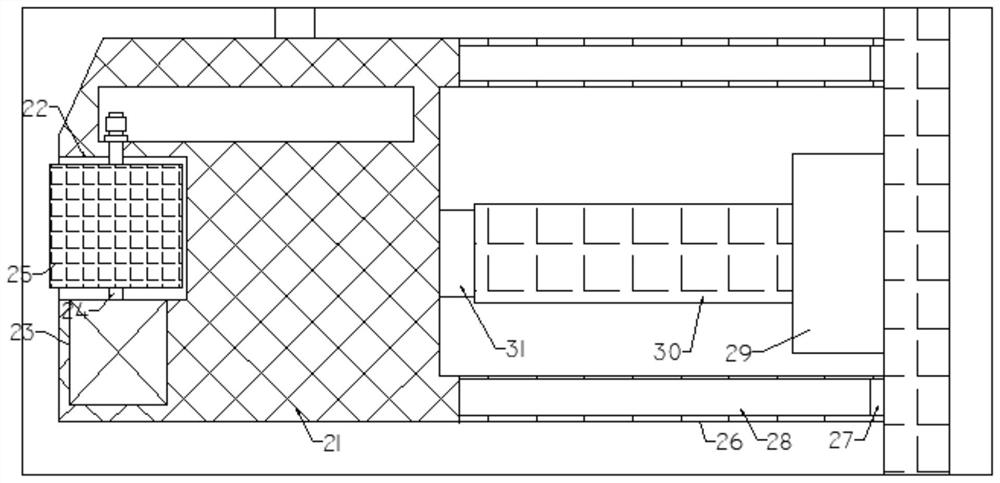

[0020] Join Figure 1-3 The electro-welding strip is applied, including the apparatus body 10, the apparatus main body 10, in which the inner wall is slidably connected to the inner wall, and the rotating body 12 is provided, the rotating body 12 The left end fixation is provided with an extruded block tube chamber 18, and a motor chamber 13 is provided in the inner wall of the motor chamber 13, and the telescopic extruder 14 left end power connection. It is provided with a rotary threaded barrel 15, and the spiral connection is provided with a moving threaded rod 16 in which the mobile thread rod 16 is fixed to the left and right sliding in the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com