Technique and device for effectively recovering waste printed circuit boards solder

A printed circuit board, soldering technology, applied in the new process field of recycling waste printed circuit board solder, can solve problems such as technical and economic constraints, and achieve the effects of easy control of conditions, no secondary pollution, and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

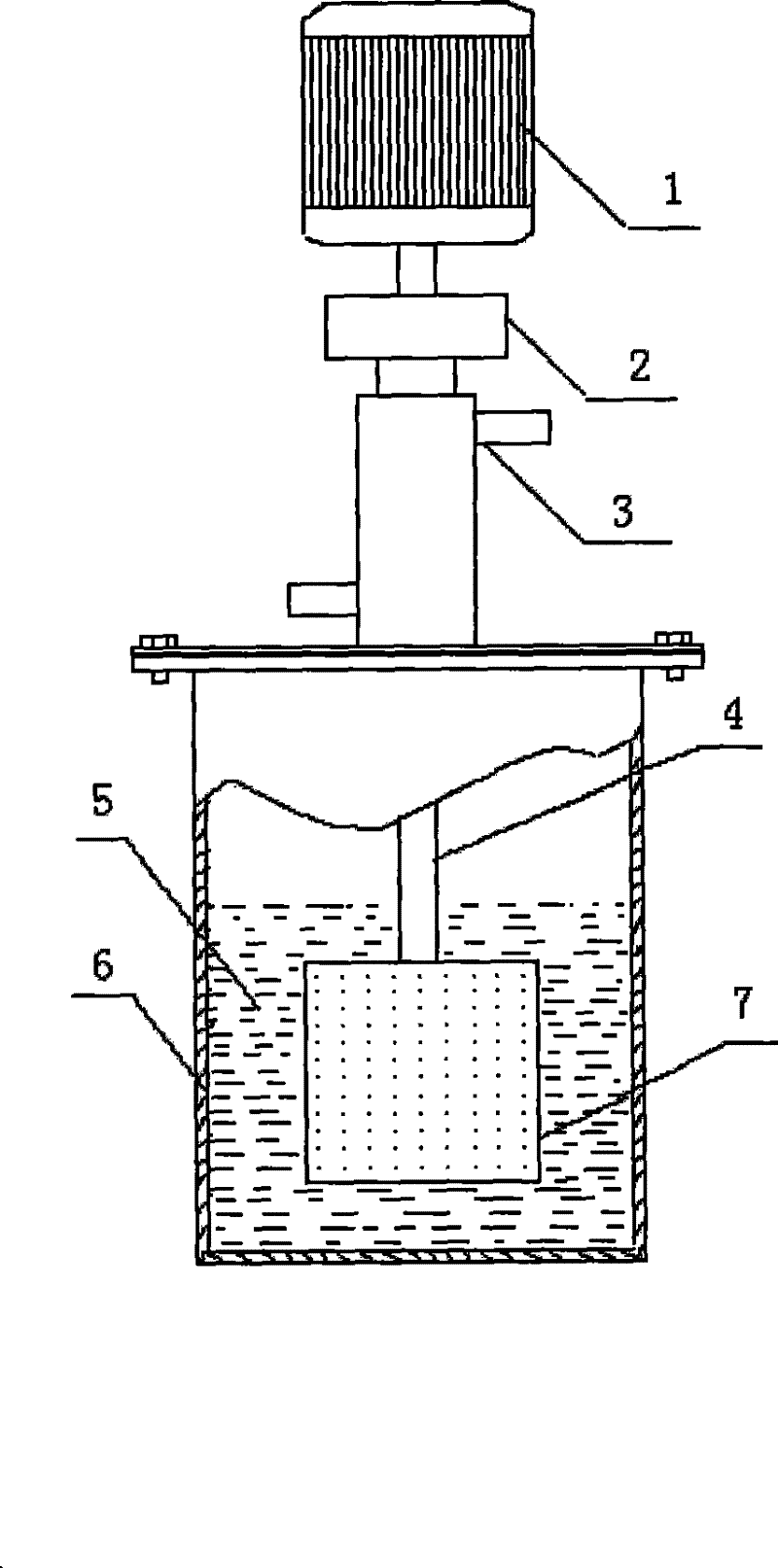

Method used

Image

Examples

Embodiment 1

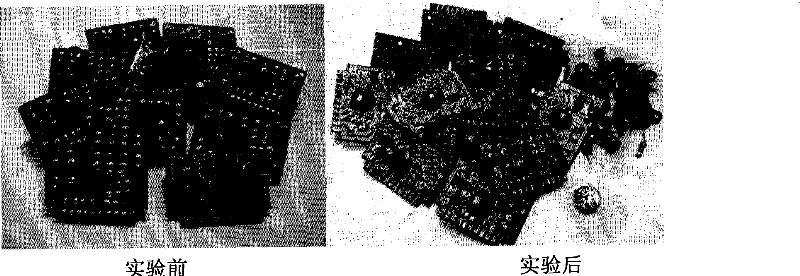

[0047] Load the waste circuit board, the oil temperature is 235°C, rotate for 5 minutes, the result is as follows figure 2 Shown:

[0048] Experimental results: Some electronic components fell off, but a large number of electronic components were attached to the circuit board; some tin fell off, but some tin remained in the soldering holes.

Embodiment 2

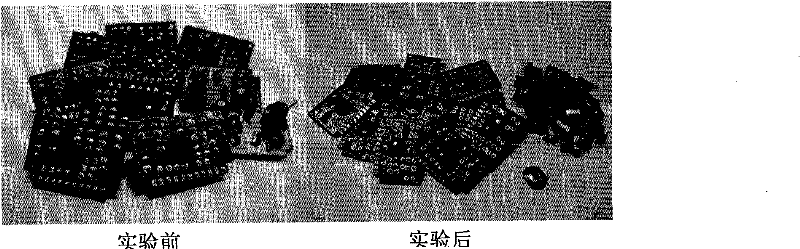

[0050] After loading the sample, the oil temperature is 240°C, and the oil is rotated twice for a total of 10 minutes. The results are as follows: image 3 Shown:

[0051] Experimental results: Most of the electronic components fell off, but there were still electronic components attached to the circuit board; a large amount of tin fell off, but a small amount of tin remained in the solder holes.

Embodiment 3

[0053] After loading the sample, the oil temperature is 240°C, rotate three times for a total of 15 minutes, and heat to 240°C before each rotation to stabilize, the results are as follows Figure 4 Shown:

[0054] Experimental results: Most of the electronic components fell off, but there were still very few electronic components attached to the circuit board; a large amount of tin fell off, but there was still a small amount of tin remaining in the soldering holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com