Thread scrape filter cleaning method

A lint filter and filter technology, which is applied to textiles and papermaking, other washing machines, household appliances, etc., can solve the problems of drain valve/drain pump blockage, washing water pollution, and inconvenient operation, so as to improve service life and improve Cleanliness, good bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

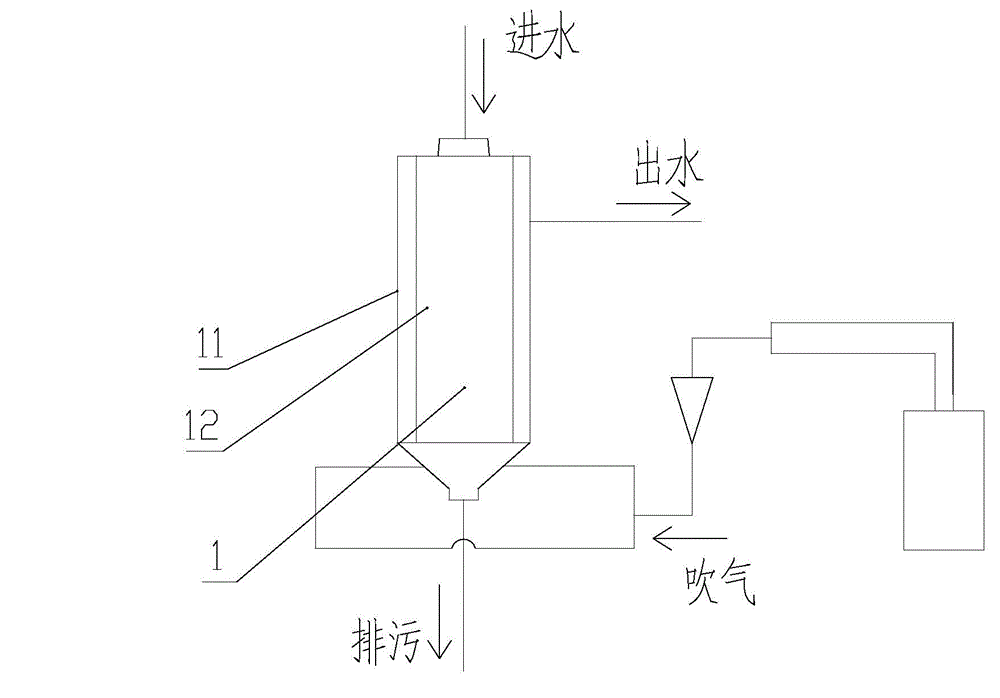

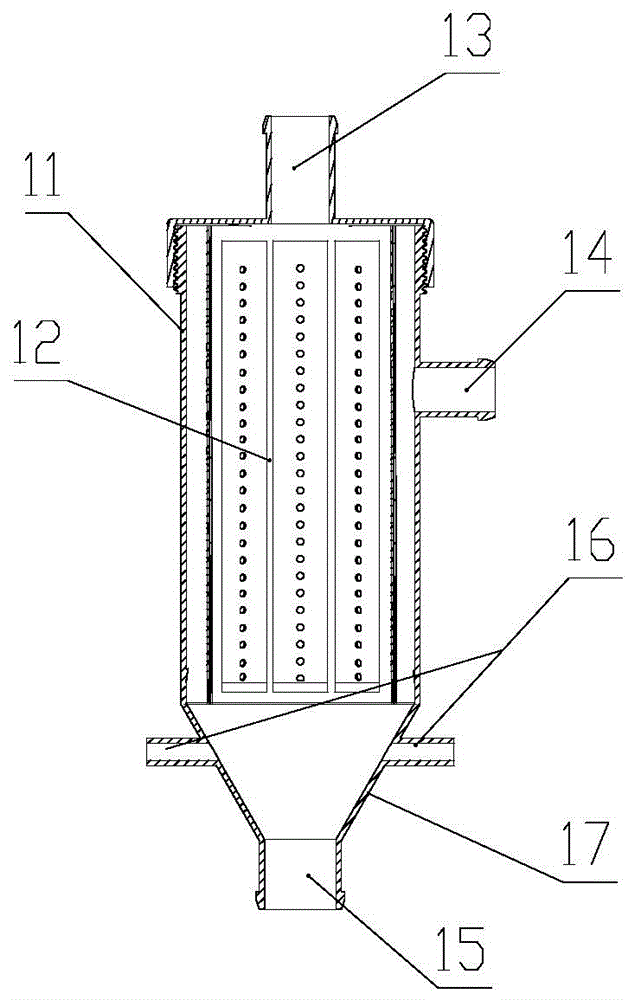

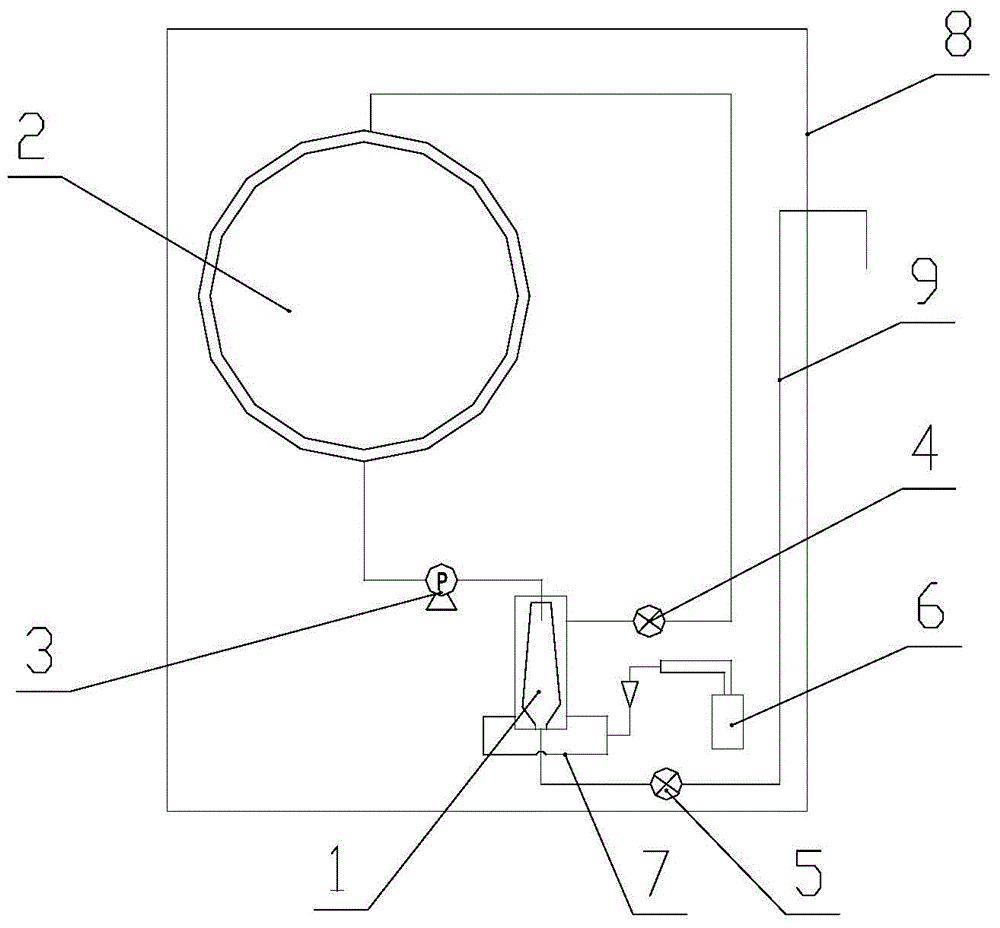

[0032] figure 2 is a schematic diagram of the structure of the filter applying the above method. As shown in the figure, the filter 1 includes a filter housing 11 and a filter screen 12 installed in the housing 11 . The housing 11 is provided with a water inlet 13, a water outlet 14 and a sewage outlet 15, the water inlet 13 is arranged on the top of the housing 11, and the water outlet 14 is arranged on the wall of the cylinder around the housing 11. In the middle part, the sewage outlet 15 is arranged at the bottom of the housing 11, and the filter screen 12 divides the inner cavity of the filter housing 11 into two parts, the inner cavity and the outer cavity, and the upper end of the inner cavity is connected with the inlet The water outlet 13 is connected, the lower end is connected with the sewage outlet 15 , and the outer cavity is connected with the water outlet 14 . Sewage flows into the inner cavity from the water inlet 13 , enters the outer cavity after being fil...

Embodiment 2

[0039] The structure of the filter in this embodiment and the washing machine with the filter are the same as those in Embodiment 1. The difference is that, in the method of air-blowing and cleaning the filter of the washing machine in this embodiment, the continuous air-blowing operation is replaced by an intermittent air-blowing operation, and the intermittent air-blowing operation includes alternate turbulence sections and intermittent sections. In the turbulence section, The air pump blows air into the filter, thereby forming a continuous disturbance to the fluid in the area where the filter screen is located; in the intermittent section, the air pump stops blowing air to allow the impurities separated from the filter screen to settle. In this way, on the one hand, the service life of the motor can be effectively improved and energy can be saved; on the other hand, when the air blowing is stopped, the fallen impurities can smoothly fall into the bottom of the filter, facili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com