Co-PCN catalyst capable of regulating active sites as well as preparation method and application of Co-PCN catalyst

A catalyst and oxidant technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of lack of directional regulation of catalyst active sites, limiting catalytic activity of catalysts, etc., to increase the number and variety , the effect of promoting release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

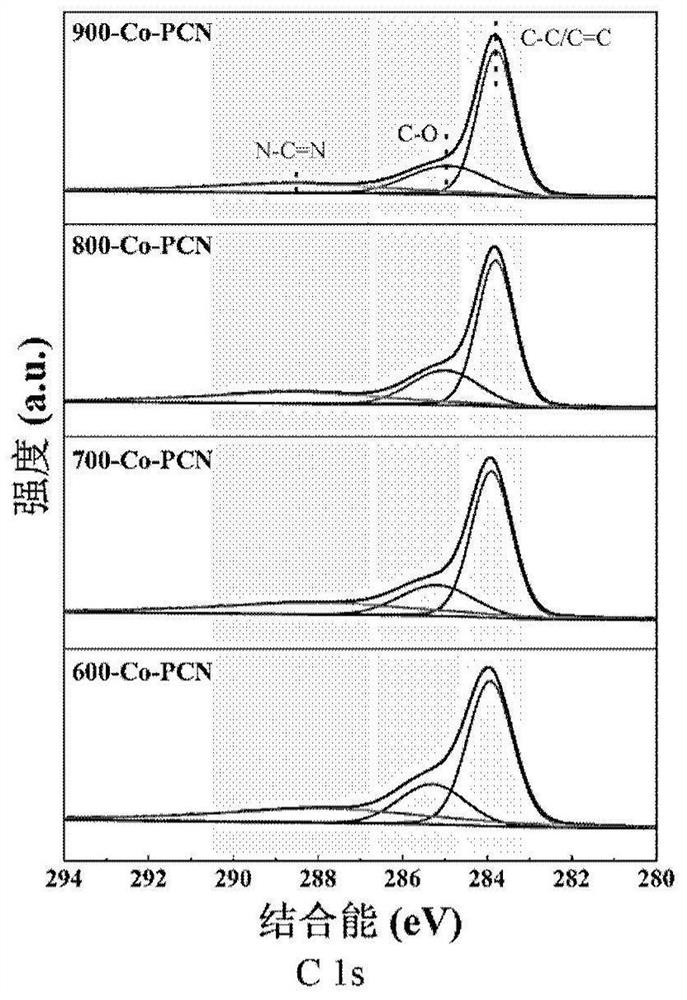

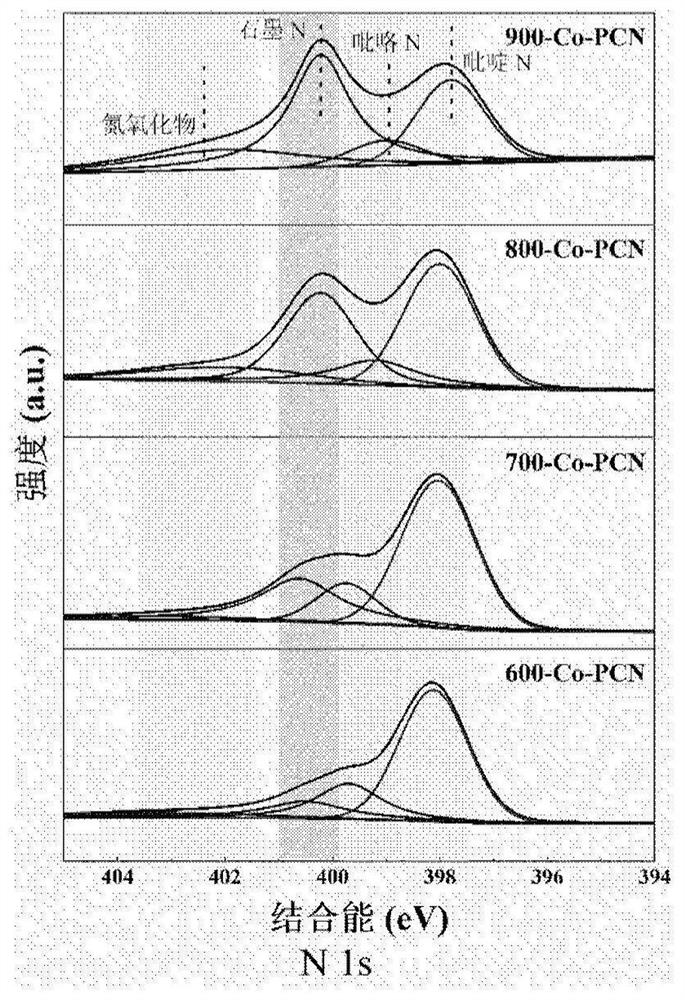

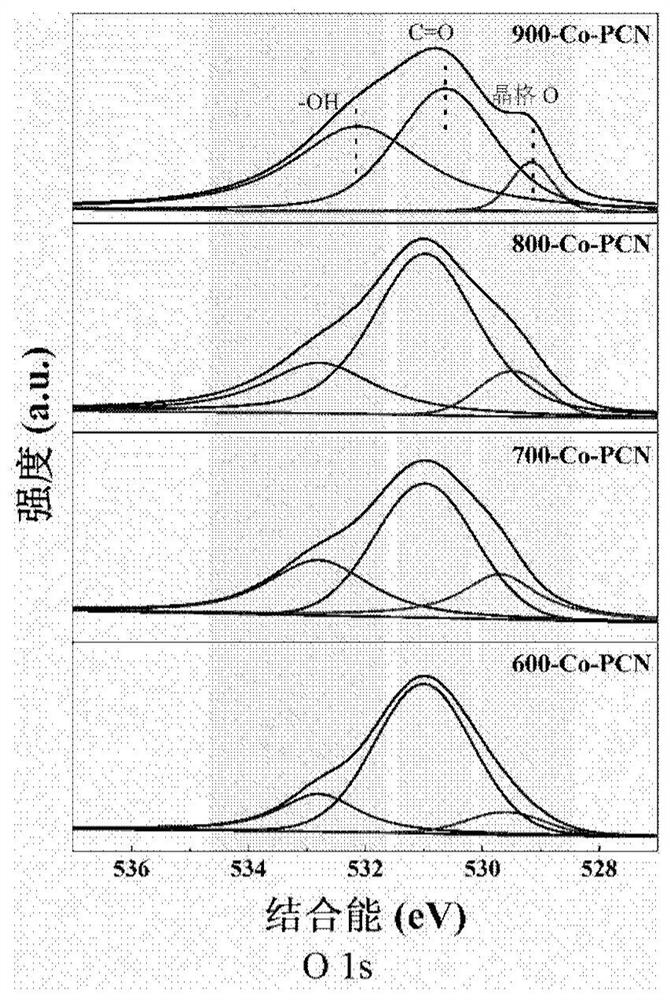

[0025] The invention discloses a preparation method of a Co-PCN catalyst, comprising:

[0026] (1) Cobalt nitrate hexahydrate methanol solution and 2-methylimidazole methanol solution are mixed to obtain the first mixed solution, and the first mixed solution is reacted to obtain Co-ZIF-L;

[0027] (2) Mix the dopamine solution and the Co-ZIF-L dispersion to obtain a second mixed solution, adjust the pH of the second mixed solution and react to obtain a Co-ZIF-L@PDA composite material;

[0028] (3) The Co-PCN catalyst was obtained by heat-treating the Co-ZIF-L@PDA composite.

[0029] In some embodiments of the present invention, in step (1), the concentration of cobalt nitrate hexahydrate in the first mixed liquid is 5-15g / L, such as 5g / L, 6g / L, 7g / L, 8g / L, 9g / L, 10g / L, 11g / L, 12g / L, 13g / L, 14g / L, 15g / L;

[0030] In some embodiments of the present invention, in step (1), the concentration of 2-methylimidazole in the first mixed solution is 10-25 g / L, such as 10 g / L, 11 g / L, ...

Embodiment 1

[0059] The application of the regulation and control of the active site in the Co-PCN catalyst to strengthen the PMS activation in this embodiment is carried out through the following steps:

[0060] 1. Preparation of Co-ZIF-L precursor: Cobalt nitrate hexahydrate was dissolved in 150 mL of anhydrous methanol to obtain cobalt nitrate hexahydrate methanol solution. 2-Methylimidazole was dissolved in 150 mL of anhydrous methanol to obtain 2-methylimidazole methanol solution. The 2-methylimidazole methanol solution was transferred to the methanol solution of cobalt nitrate hexahydrate to obtain 300 mL of the mixed solution, which was stirred at room temperature for 30 min and then left to stand for 12 h. Pour off the supernatant, centrifuge the suspension at a speed of 4000r / min for 5min, wash with absolute ethanol and deionized water for 3 times, then place it in a blast drying oven at 60°C for 12h to dry, and finally use Co-ZIF-L solids were ground in an agate mortar and pestl...

Embodiment 2

[0070] The application of the regulation and control of the active site in the Co-PCN catalyst to strengthen the PMS activation in this embodiment is carried out through the following steps:

[0071] 1. Preparation of Co-ZIF-L precursor: Cobalt nitrate hexahydrate was dissolved in 150 mL of anhydrous methanol to obtain cobalt nitrate hexahydrate methanol solution. 2-Methylimidazole was dissolved in 150 mL of anhydrous methanol to obtain 2-methylimidazole methanol solution. The 2-methylimidazole methanol solution was transferred to the methanol solution of cobalt nitrate hexahydrate to obtain 300 mL of the mixed solution, which was stirred at room temperature for 30 min and then left to stand for 12 h. Pour off the supernatant, centrifuge the suspension at a speed of 2000r / min for 10min, wash with absolute ethanol and deionized water for 3 times respectively, then place it in a blast drying oven at 80°C for 6h to dry, and finally use Co-ZIF-L solids were ground in an agate mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com