Method for preparing modified biochar

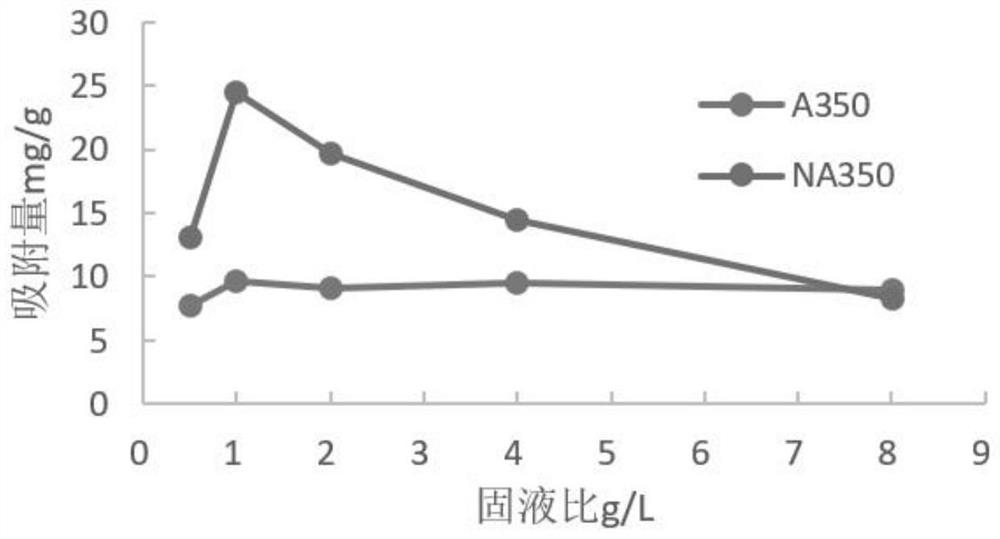

A biochar modification technology, applied in chemical instruments and methods, water pollutants, alkali metal compounds, etc., can solve problems such as high cost of modifiers, secondary pollution of harmful substances, and decreased adsorption performance, and achieve enhanced adsorption The effects of stability, enhanced adsorption capacity, and developed pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

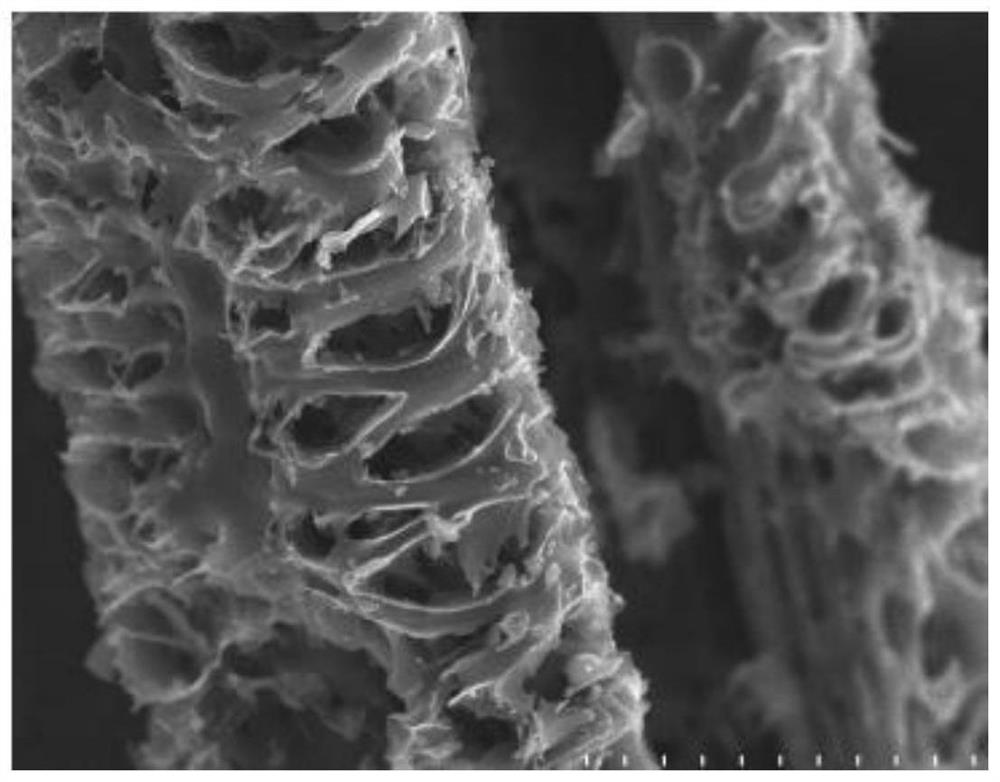

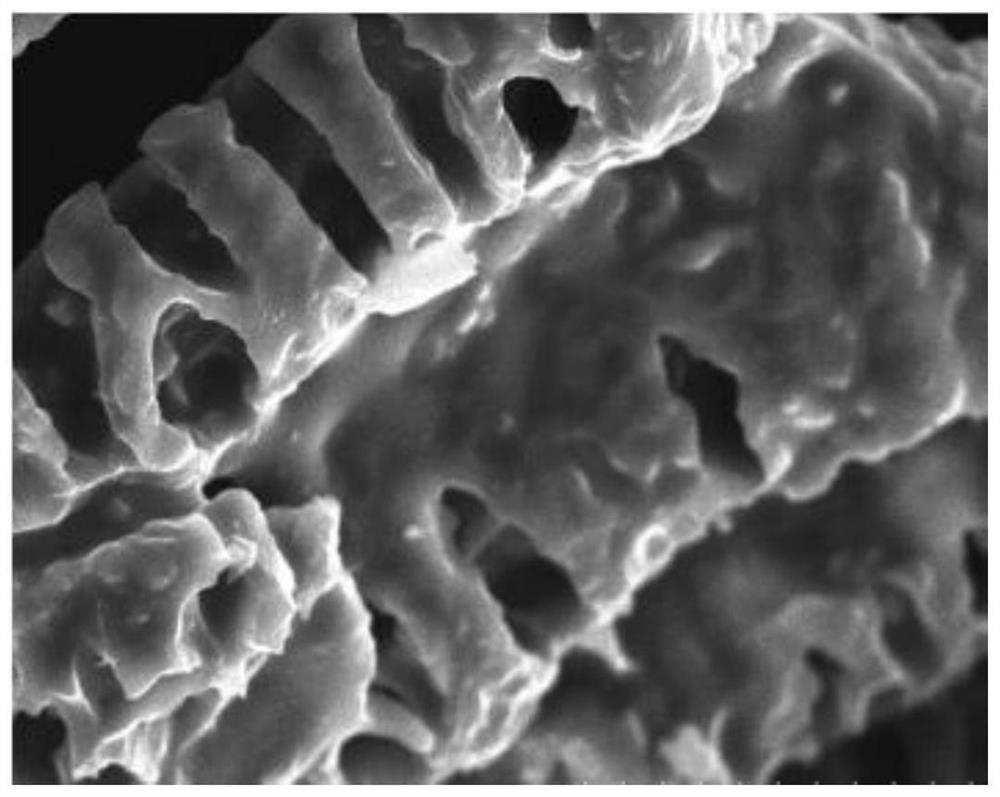

[0023] Such as Figure 6 As shown, (1) Wash the rice husk with ultrapure water three times, place it in an oven at 60°C, dry it to constant weight, put it into a 100mL crucible, and wrap tinfoil paper on the outside of the crucible, fill it up and seal it tightly. ;

[0024] (2) Put it into a muffle furnace to isolate the air and heat it. After the temperature rises to 350°C, pyrolyze it for 2 hours, take it out and cool it, and pass it through a 250 μm sieve to obtain rice husk charcoal;

[0025] (3) Get 10g of rice husk charcoal obtained in step (2), add 100g of hydrochloric acid and stir and soak in a magnetic stirrer for 24 hours, then wash and filter with ultrapure water, then add 100g of sodium hydroxide and stir and soak in a magnetic stirrer for 24 hours before using Wash and filter with ultrapure water, and finally add 100g of ethanol to a magnetic stirrer to stir and soak for 24 hours, then wash with ultrapure water and filter with suction, and then dry to obtain pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com