Defoaming equipment for methyl salicylate production

A technology of methyl salicylate and equipment is applied in the field of defoaming equipment for the production of methyl salicylate to achieve the effects of increasing the speed of defoaming and avoiding volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

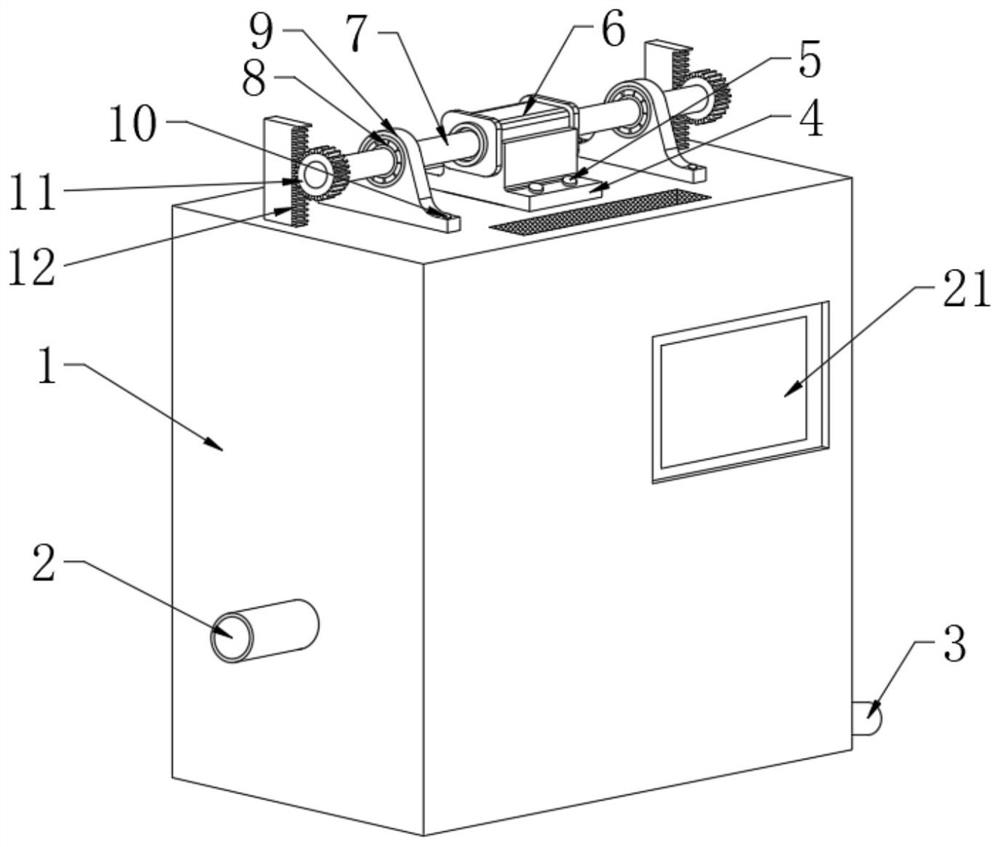

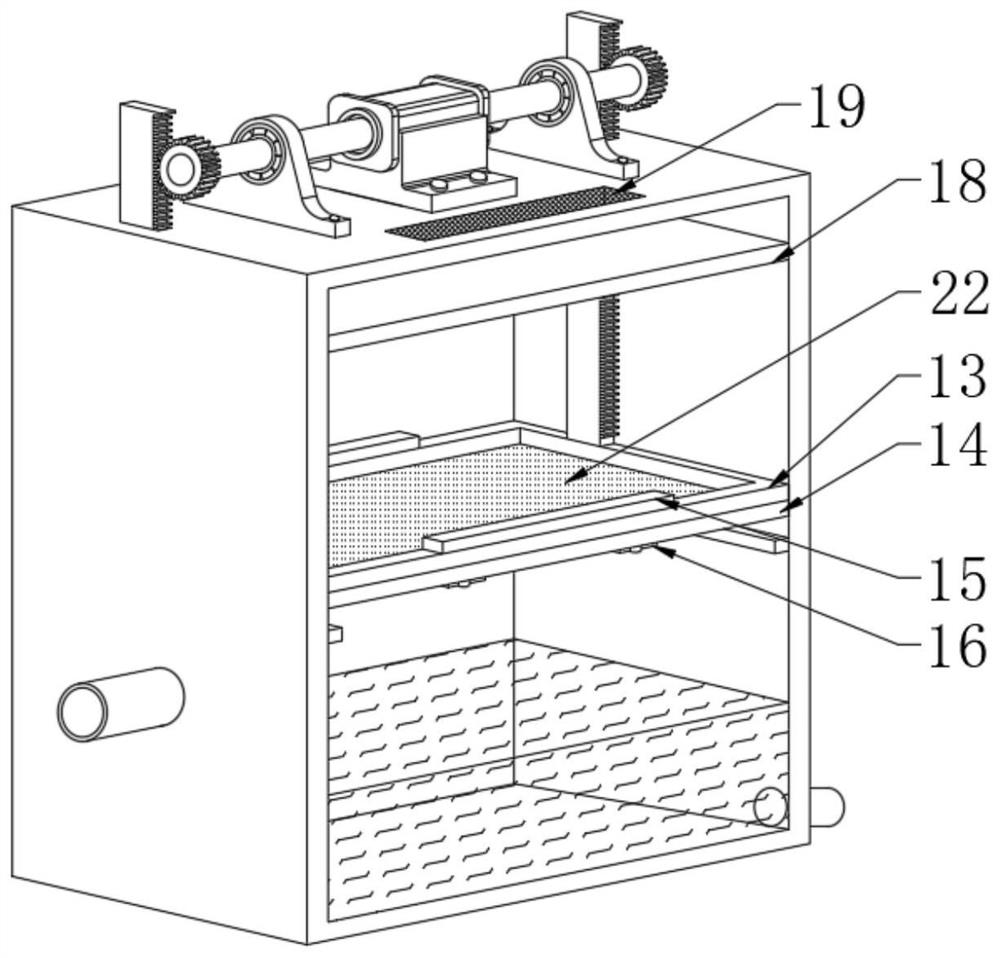

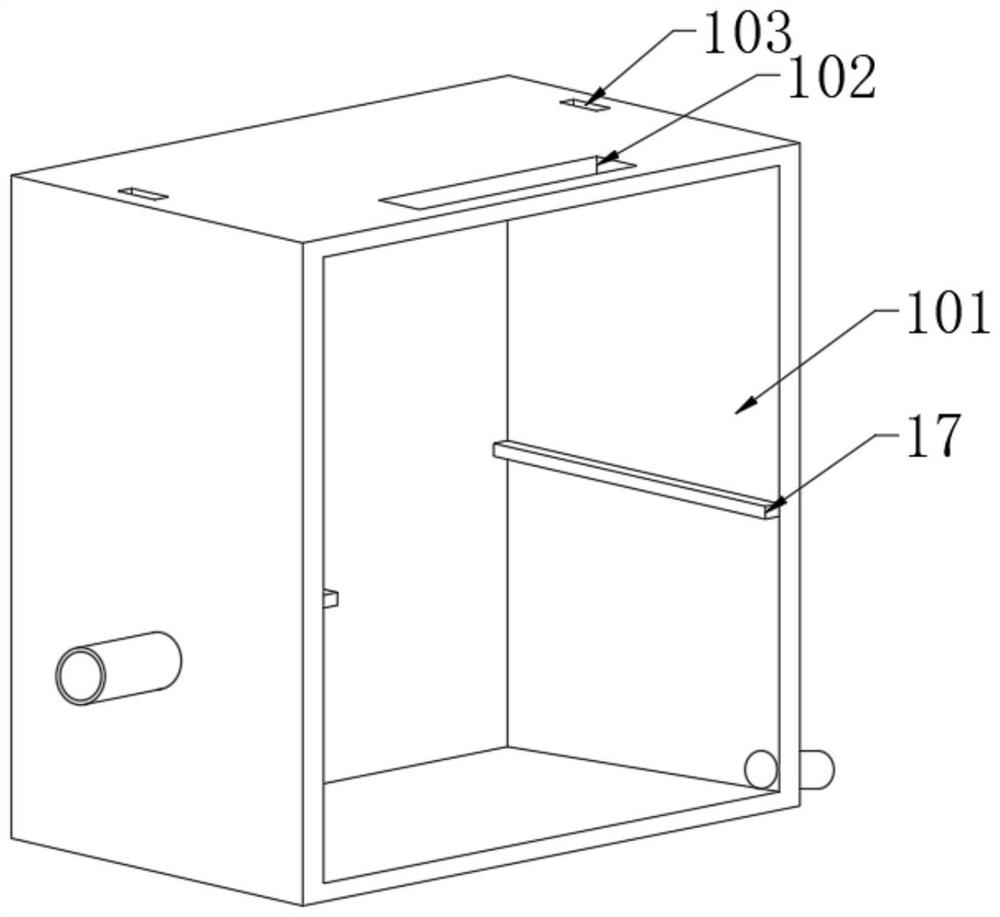

[0031] see Figure 1-7 , a kind of defoaming equipment for the production of methyl salicylate, comprising an installation shell 1, the left side of the installation shell 1 is provided with a foam inlet 2, the right side of the installation shell 1 is provided with a water outlet 3, and the front of the installation shell 1 is provided with The operation panel 21, the upper surface of the installation shell 1 is threaded with a U-shaped connecting seat 4 through the first fixing bolt 5, and the inside of the U-shaped connecting seat 4 is fixedly connected with a forward and reverse motor 6, and the left and right output ends of the forward and reverse motor 6 Both are welded with a connecting shaft 7, and the end of the connecting shaft 7 away from the forward and reverse motor 6 is movably connected with a fixed seat 9 through a bearing 8, and the bottom of the fixed seat 9 is threaded with the top of the installation shell 1 through a second fixing bolt 10, and the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com