A centrifugal pouring method for water glass investment casting

A technology of investment casting and centrifugal casting, which is applied in the field of casting and casting, can solve the problems of shrinkage cavities, shrinkage porosity, and unqualified castings, and achieve the effects of accelerating filling, reducing static pressure and preventing volume expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

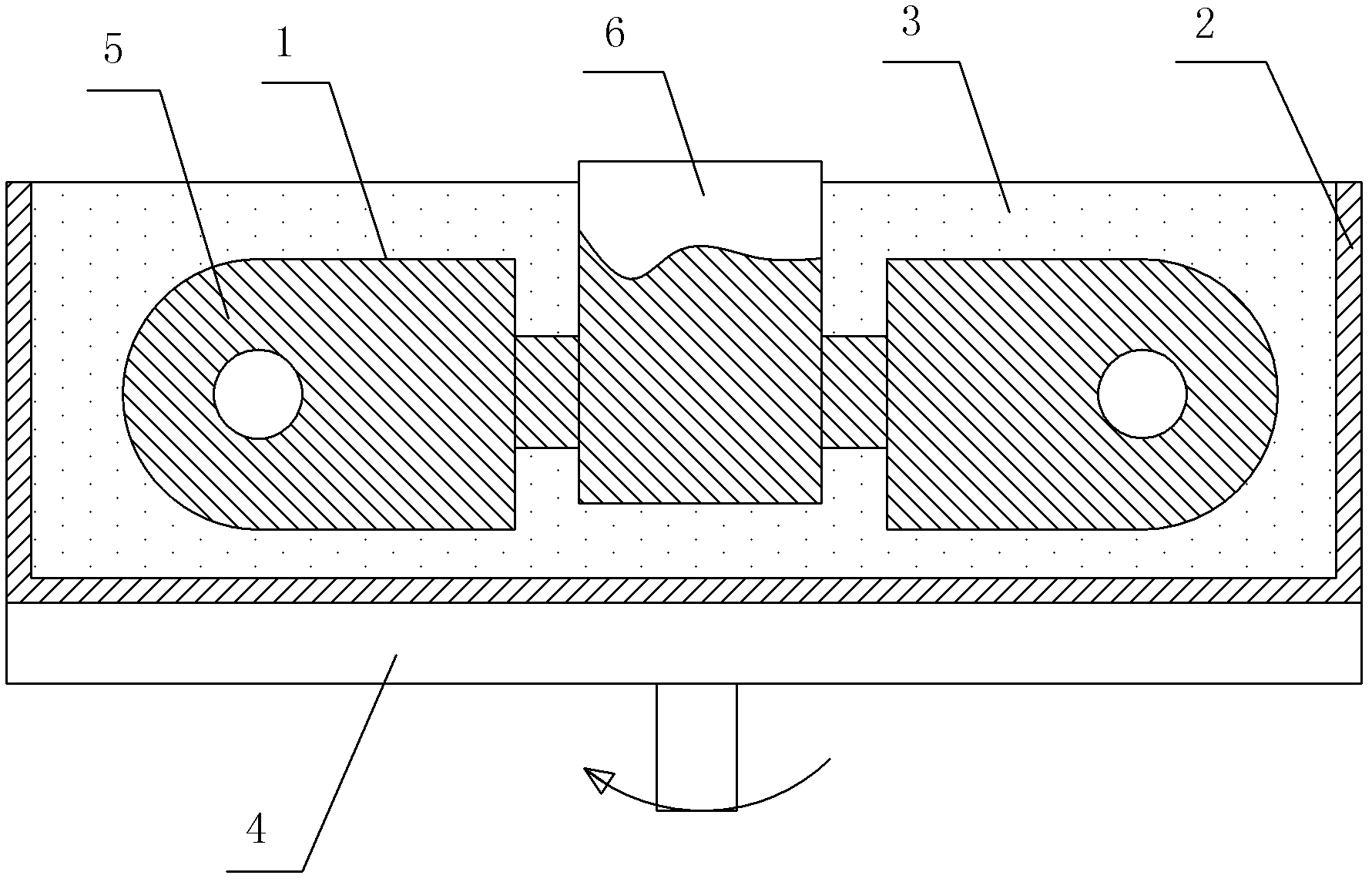

[0011] Embodiment one: if figure 2 As shown, the effective length of the static pressure generated on the sprue 6 is 0.6 times of the effective length of the static pressure of the original sprue 7, reducing the static pressure head and reducing the pressure on the water glass shell 1. Put the water glass shell 1 into the iron box 2, embed the steel sand 3 to reinforce the water glass shell 1, prevent the water glass shell 1 from expanding, pour the molten iron 5 through the sprue 6, and after standing for 30 seconds, the centrifugal rotary table 4 Rotate at a rate of 80 rpm for 10 minutes to obtain a casting, and there is no "shrinkage cavity" or "shrinkage porosity" casting defect at the anatomical hot joint of the casting.

Embodiment 2

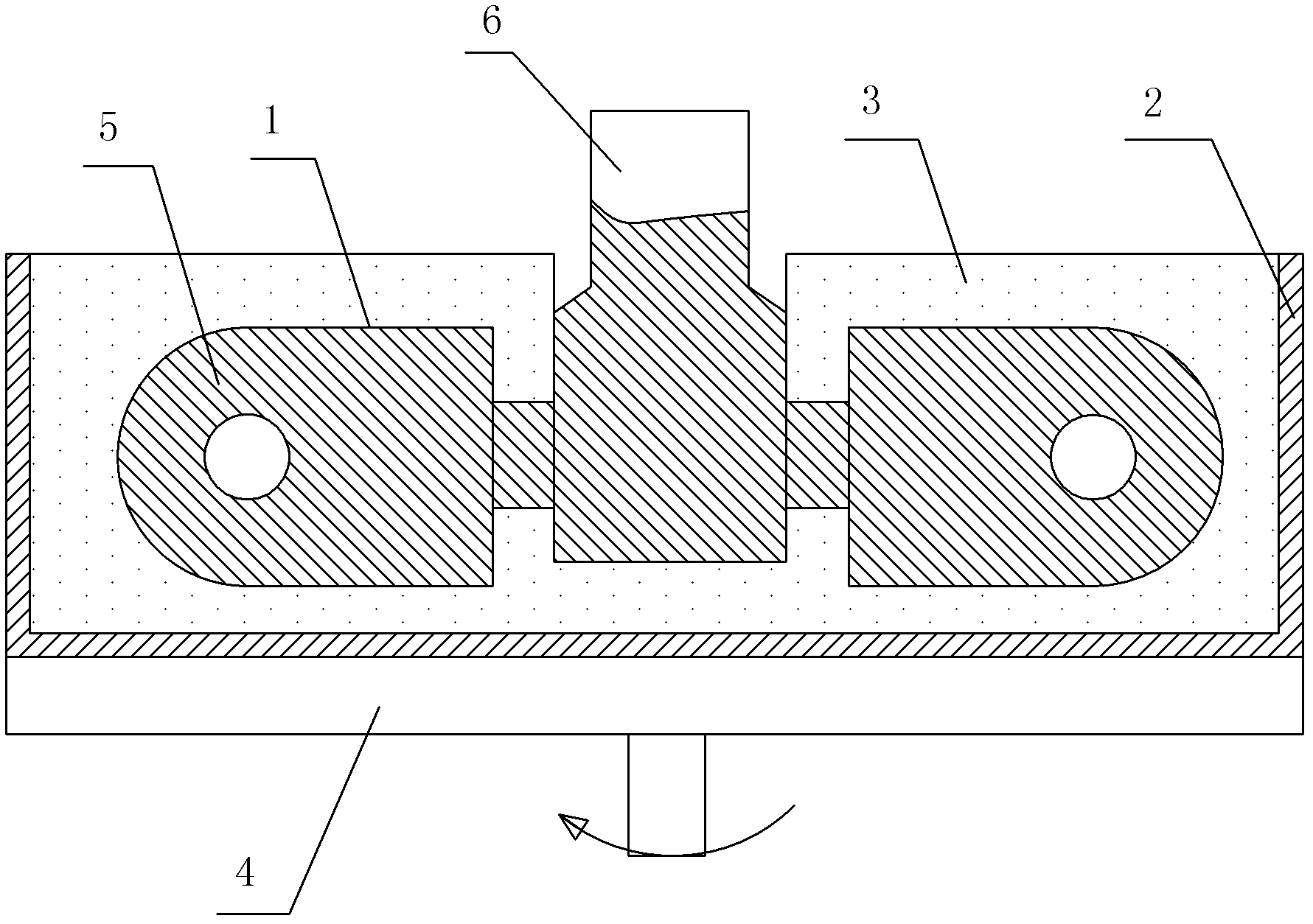

[0012] Embodiment two: if image 3 As shown, the diameter of the sprue 6 is 0.8 times the diameter of the original sprue 7, which reduces the static pressure head and reduces the pressure for the water glass shell 1. Put the water glass shell 1 into the iron box 2, embed the steel sand 3 to reinforce the water glass shell 1, prevent the water glass shell 1 from expanding, pour the molten iron 5 through the sprue 6, and after standing for 30 seconds, the centrifugal rotary table 4 Rotate at a rate of 100 rpm for 15 minutes to obtain a casting, and there is no "shrinkage cavity" or "shrinkage porosity" casting defect at the anatomical hot joint of the casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com