Two-dimensional structure selenium telluride modified carbon fiber electrode material and preparation method thereof

A carbon fiber electrode and two-dimensional structure technology, applied in structural parts, battery electrodes, secondary batteries, etc., can solve the problems of energy density discount, unfavorable practical application of transition metal selenium, etc., achieve high stability and energy density, and improve utilization The effect of high efficiency, stability, and small volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

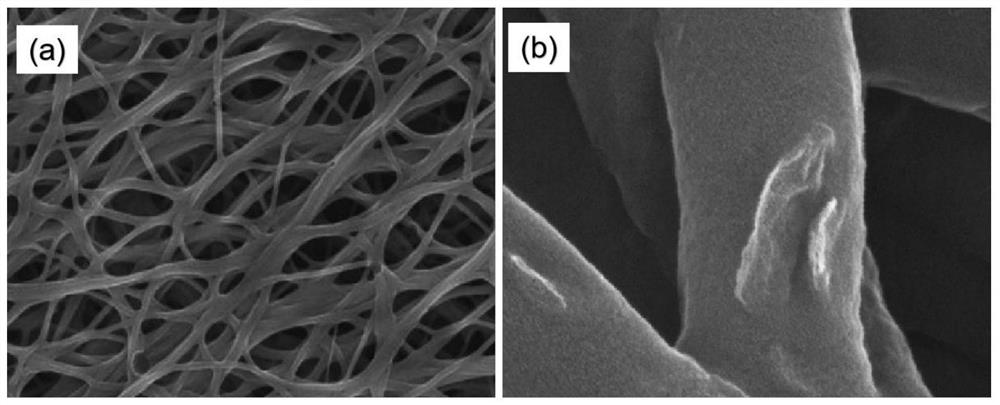

[0019] Embodiment 1: In this embodiment, a kind of MoSe is provided 2 / carbon nanofiber self-supporting material preparation method, the specific preparation method is as follows:

[0020] (1) Add 500 mg MoS 2 After the powder was fully mixed with 50 mL N,N-dimethylformamide, 0.25 mg / ml MoS was obtained after 6 hours of ultrasonic intercalation, centrifugation and washing for 3 times. 2 Dispersions.

[0021] (2) 8ml MoS 2 The dispersion liquid and 1 g of polyacrylonitrile powder were fully dissolved in N,N-dimethylformamide to prepare a spinning solution.

[0022](3) Electrospinning the spinning solution obtained in step (2) to obtain polyacrylonitrile 2D MoS 2 / PAN composite nanofiber membrane, the operating parameters of electrospinning are: voltage 12 KV, receiving distance 12 cm, flow rate 1 mL / h.

[0023] (4) For step (3) to get 2D MoS 2 / PAN composite nanofiber membrane placed in a tube furnace for pre-stabilization and carbonization to obtain 2D MoS 2 / CNF membr...

Embodiment 2

[0025] Embodiment 2: In this embodiment, a kind of WTe is provided 2 / carbon nanofiber self-supporting material preparation method, the specific preparation method is as follows:

[0026] (1) Add 200 mg WS 2 After the powder was fully mixed with 30 mL N,N-dimethylformamide, after 10 h ultrasonic intercalation stripping, centrifugation and washing three times, 0.2 mg / ml WS was obtained. 2 Dispersions.

[0027] (2) 25ml WS 2 The dispersion liquid and 2 g of polyacrylonitrile powder were fully dissolved in N,N-dimethylformamide to prepare a spinning solution.

[0028] (3) Electrospinning the spinning solution obtained in step (2) to obtain polyacrylonitrile 2D WS 2 / PAN composite nanofiber membrane, the electrospinning operating parameters are: voltage 15 KV, receiving distance 10 cm, flow rate 2 mL / h.

[0029] (4) For step (3) to get 2D WS 2 / PAN composite nanofiber membranes were pre-stabilized and carbonized in a tube furnace to obtain 2D WS 2 / CNF membrane, the pretre...

Embodiment 4

[0031] Embodiment 4: In this embodiment, a preparation method of WSe / carbon nanofiber self-supporting material is provided, and the specific preparation method is as follows:

[0032] (1) Mix 100 mg WS 2 After the powder was fully mixed with 30 mL N,N-dimethylformamide, after 4 hours of ultrasonic intercalation stripping, centrifugation and washing for 3 times, 0.25 mg / ml WS was obtained. 2 Dispersions.

[0033] (2) Fully dissolve 1 gram of polyacrylonitrile powder in N,N-dimethylformamide to prepare a spinning solution with a concentration of 10%.

[0034] (3) The spinning solution obtained in step (2) was subjected to electrospinning technology to obtain polyacrylonitrile nanofiber membrane. The operating parameters of electrospinning were: voltage 15 KV, receiving distance 10 cm, and flow rate 1 mL / h.

[0035] (4) Place the PAN film obtained in step (2) on the 2D WS obtained in (1) 2 Ultrasonic immersion in the dispersion for 30 min, placed in a freeze dryer for freeze-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com