Paste mixing and brick making preparation method of lithium ion battery pole piece

A lithium-ion battery and pole piece technology, which is applied in electrode manufacturing, battery electrodes, batteries, etc., can solve the problems of ion battery pole piece burrs, poor consistency of film compaction density, long and cumbersome manufacturing process of battery pole pieces, etc., to achieve Avoid inconsistent coating thickness, improve battery safety performance, and solve the effect of slurry transportation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

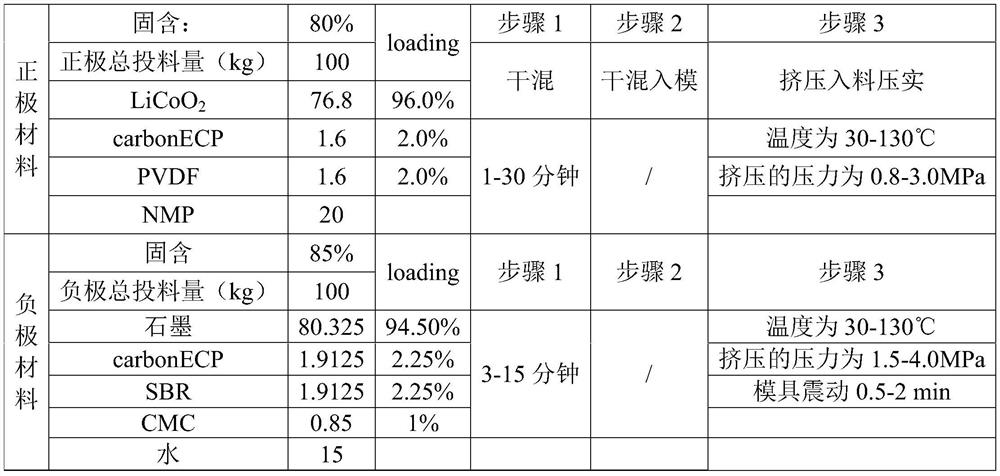

[0031] The invention relates to a preparation method for making bricks from a composite paste of a lithium-ion battery pole piece, which mainly comprises three steps of making paste, feeding the paste into a mold, and drying and compacting.

[0032] The first step is to make the paste. First, according to the process ratio, dry mix the raw material powder for 2 to 6 minutes; add solvent to the dry mixed material, and obtain different addition amounts according to different types of powder experiments; powder and Solvents are machine mixed to make a paste.

[0033] Among them, the negative electrode raw materials include: graphite, conductive agent, thickener (CMC), binder (SBR), copper foil; the specific dosage is: negative electrode material (graphite): 94.5%, conductive agent (Carbon ECP): 1.0 % (Ketjen superconducting carbon black), binder (SBR): 2.25% (SBR = styrene-butadiene rubber latex), thickener (CMC): 2.25% (CMC = sodium carboxymethylcellulose).

[0034] Finally, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com