High-temperature-resistant dry-type capacitor

A capacitor and high temperature resistant technology, applied in the field of capacitors, can solve problems such as dry capacitor damage, stability impact, accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

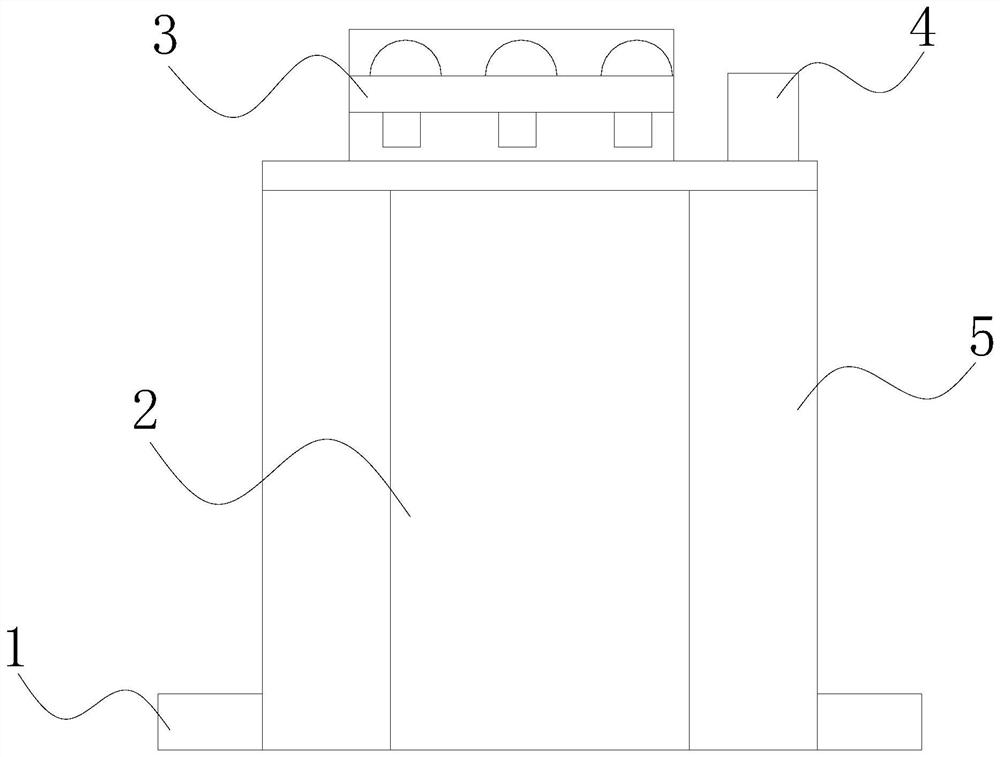

[0031] see figure 1 , the present invention provides a technical solution: a high temperature resistant dry capacitor, its structure includes a base 1, a capacitor core 2, an electrode 3, a body 4, and a protective device 5, the base 1 is installed on the protective device 5, the The protection device 5 is provided with a main body 4 connected thereto, and the main body 4 is provided with a capacitor core 2 inside, and the capacitor core 2 is electrically connected to the electrode 3 .

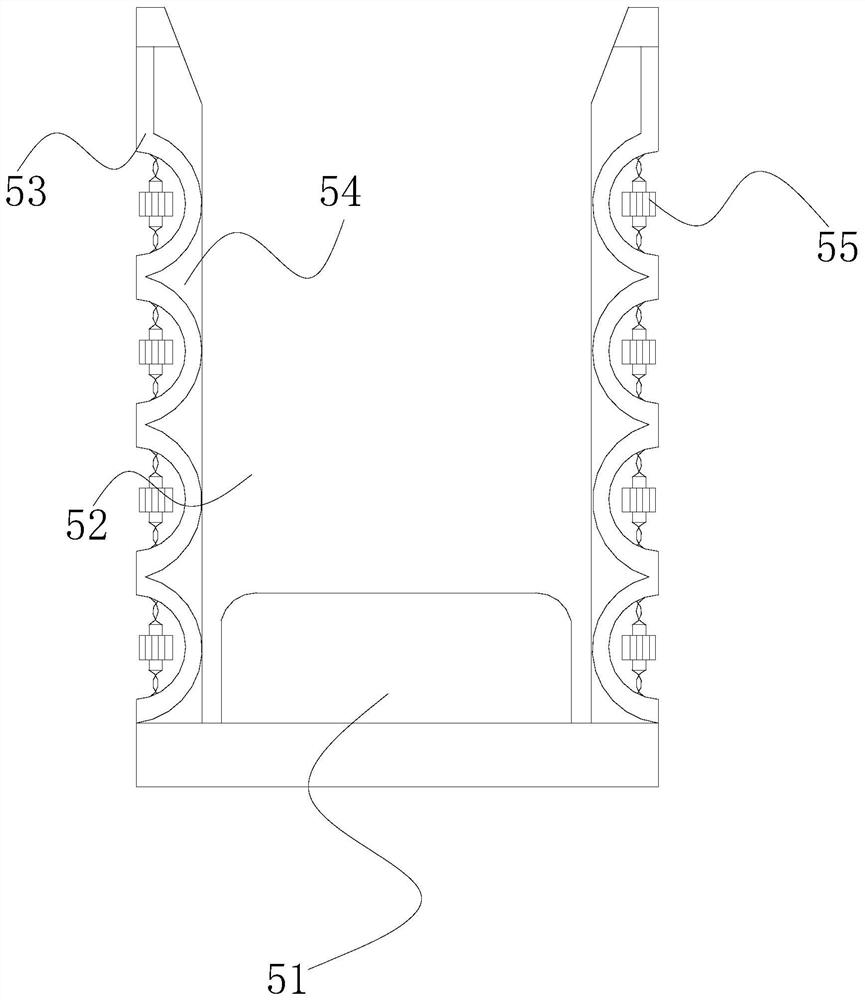

[0032] see figure 2 , the protective device 5 includes a limiting component 51, a placement cavity 52, a connecting plate 53, a guide 54, and a dehumidifying component 55. Both sides of the limiting component 51 are provided with guides 54 connected thereto. The guide 54 is in communication with the connection plate 53, and the end of the connection plate 53 away from the guide 54 is fastened to the dehumidification assembly 55. There are eight dehumidification assemblies 55, and the eight ...

Embodiment 2

[0042] see figure 1 , the present invention provides a technical solution: a high temperature resistant dry capacitor, its structure includes a base 1, a capacitor core 2, an electrode 3, a body 4, and a protective device 5, the base 1 is installed on the protective device 5, the The protection device 5 is provided with a main body 4 connected thereto, and the main body 4 is provided with a capacitor core 2 inside, and the capacitor core 2 is electrically connected to the electrode 3 .

[0043] see figure 2 , the protective device 5 includes a limiting component 51, a placement cavity 52, a connecting plate 53, a guide 54, and a dehumidifying component 55. Both sides of the limiting component 51 are provided with guides 54 connected thereto. The guide 54 is in communication with the connection plate 53, and the end of the connection plate 53 away from the guide 54 is fastened to the dehumidification assembly 55. There are eight dehumidification assemblies 55, and the eight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com