Environment-friendly low-smoke halogen-free flame-retardant power cable

An environmentally friendly technology for power cables, applied in the field of environmentally friendly low-smoke, halogen-free, and flame-retardant power cables, can solve problems such as the anti-ultraviolet layer has no good anti-aging ability, the outer sheath layer does not have flame-retardant effects, and rescue work is difficult. Effects of increasing glass transition temperature, reducing crosslink density, and strong tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

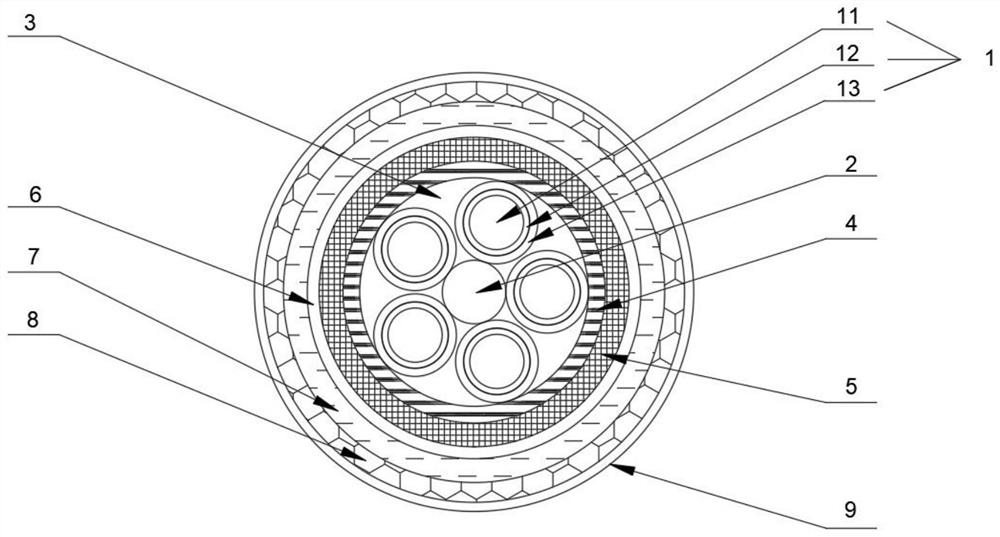

[0044] Such as figure 1 As shown, an environmentally friendly low-smoke halogen-free flame-retardant power cable provided in this embodiment includes a core assembly 1 and a central filling rope 2 from the inside to the outside. The core assembly 1 is twisted in the same direction around the central filling rope 2. The wire core assembly 1 includes a wire core body 11. The outer surface of the wire core body 11 is covered with an inner shielding layer 12. The outer surface of the inner shielding layer 12 is covered with an insulating layer 13. The outer surface of the insulating layer 13 is fixedly connected to the outer shielding layer 4. The outer shielding layer Fireproof filler 3 is filled between layer 4 and insulating layer 13, the outer surface of outer shielding layer 4 is fixedly connected with inner sheath layer 5, and the outer surface of inner sheath layer 5 is sequentially connected with armored layer 6, fireproof layer 7, and outer sheath layer 8 and UV protectio...

Embodiment 2

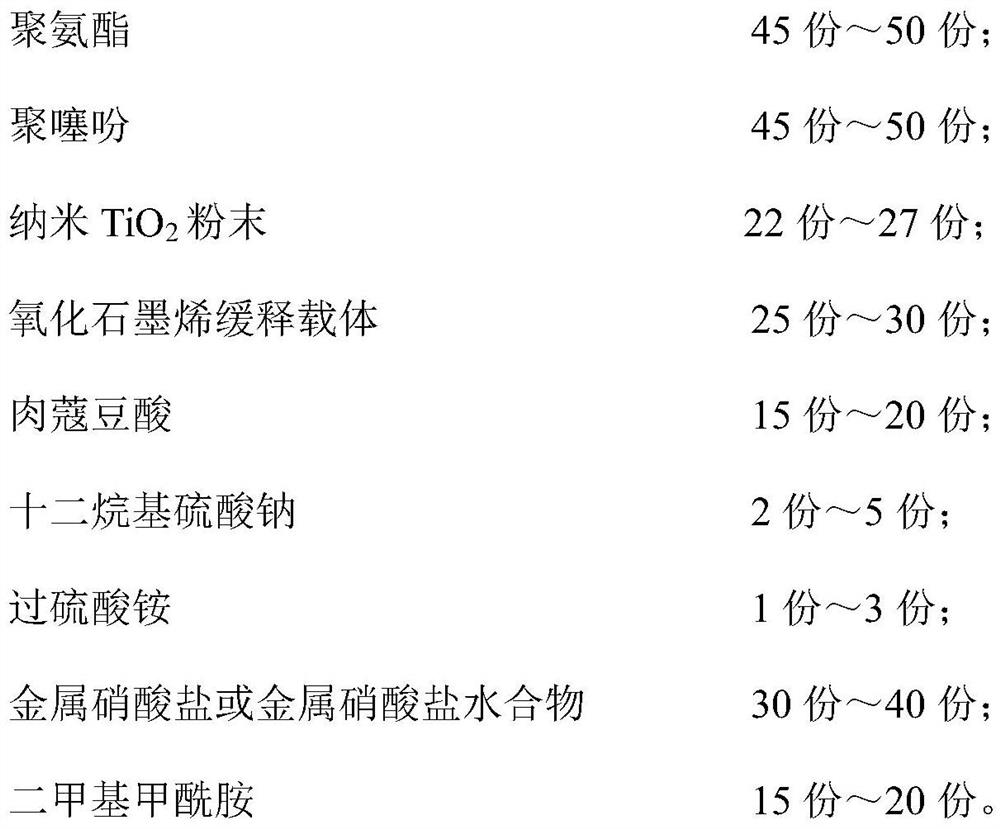

[0073] The difference between this embodiment and embodiment 1 is that the material of the UV protection layer includes the following components by weight components:

[0074]

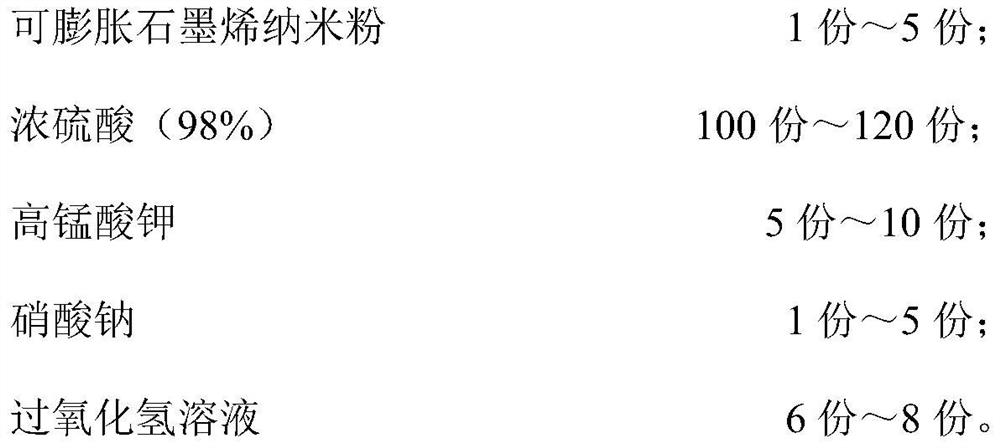

[0075] Wherein, the preparation material of graphene oxide slow-release carrier, by weight component, includes the following components:

[0076]

[0077] The preparation method of graphene oxide slow release carrier, comprises the following steps:

[0078] 1) 4 parts of expandable graphene nanopowders are dissolved in 110 parts of mass fraction as 98% concentrated sulfuric acid, stirred at 62.5rpm for 1.25h, then 7.5 parts of potassium permanganate and 3 parts of sodium nitrate are added , stirred at 125rpm for 18h;

[0079] 2) After adding 750ml of distilled water to the mixture obtained in step 1), add 7 parts of hydrogen peroxide solution to terminate the oxidation reaction to obtain a graphene oxide mixture;

[0080] 3) After the graphene oxide mixture obtained in step 2) was left to stand...

Embodiment 3

[0090] The difference between this embodiment and embodiment 1 and embodiment 2 is that the material of the UV protection layer includes the following components by weight components:

[0091]

[0092] The preparation material of graphene oxide sustained-release carrier, by weight component, includes the following components:

[0093]

[0094] The preparation method of graphene oxide slow release carrier, comprises the following steps:

[0095] 1) 5 parts of expandable graphene nanopowders are dissolved in 120 parts of massfraction in the concentrated sulfuric acid of 98%, stir 1.5h with 75rpm rotating speed, then add 10 parts of potassium permanganate and 5 parts of sodium nitrate, Stir at 150rpm for 24h;

[0096] 2) After adding 850ml of distilled water to the mixture obtained in step 1), add 8 parts of hydrogen peroxide solution to terminate the oxidation reaction to obtain a graphene oxide mixture;

[0097] 3) After the graphene oxide mixture obtained in step 2) wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com