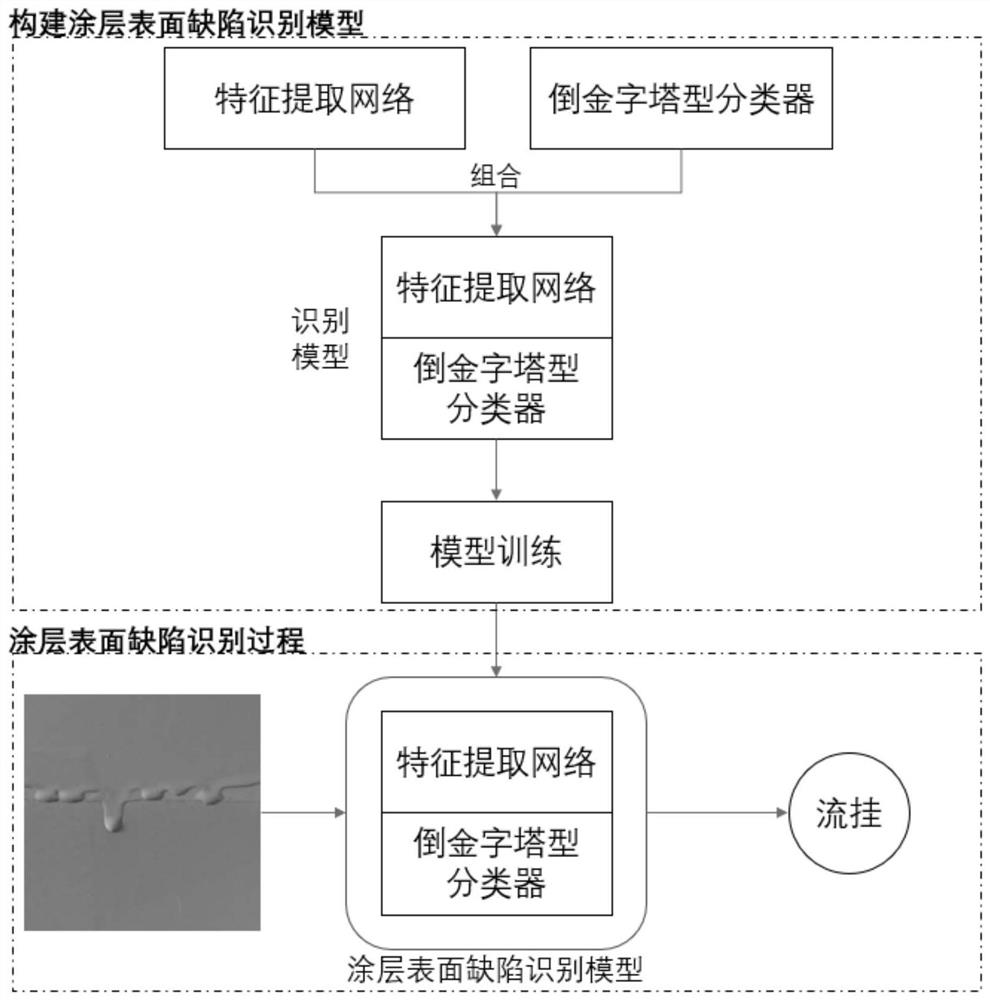

A Deep Learning-Based Coating Surface Defect Recognition Method

A defect recognition and deep learning technology, applied in neural learning methods, character and pattern recognition, image enhancement and other directions, can solve the problems of poor recognition accuracy and speed, and achieve the effect of fast and high-precision classification and recognition operations and fast extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

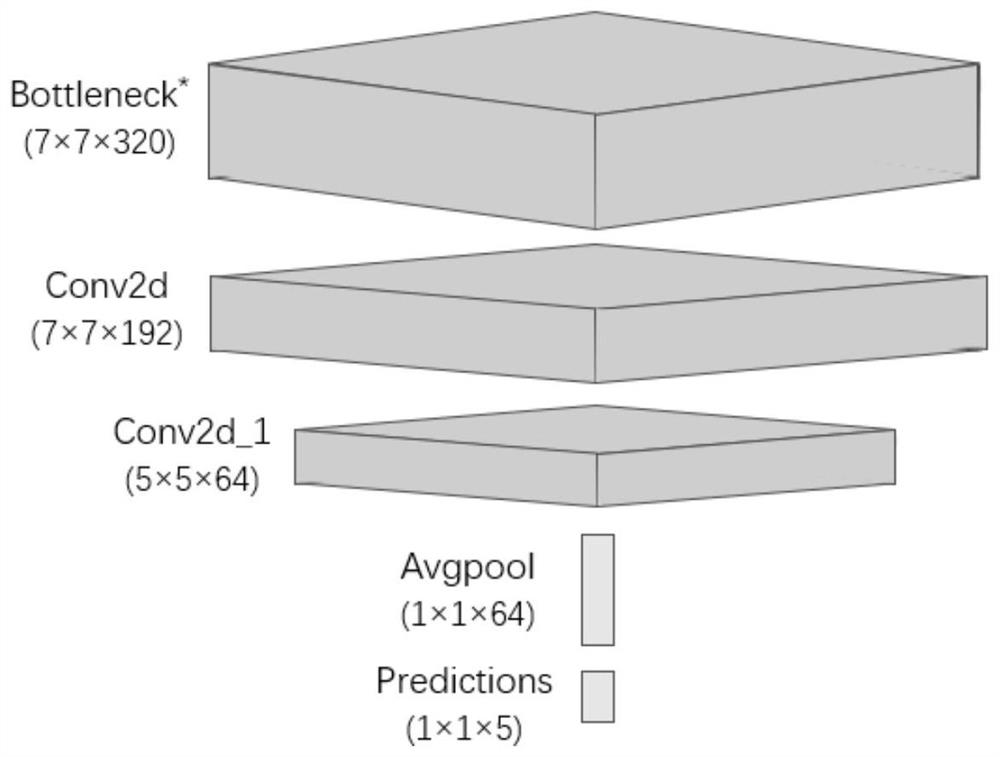

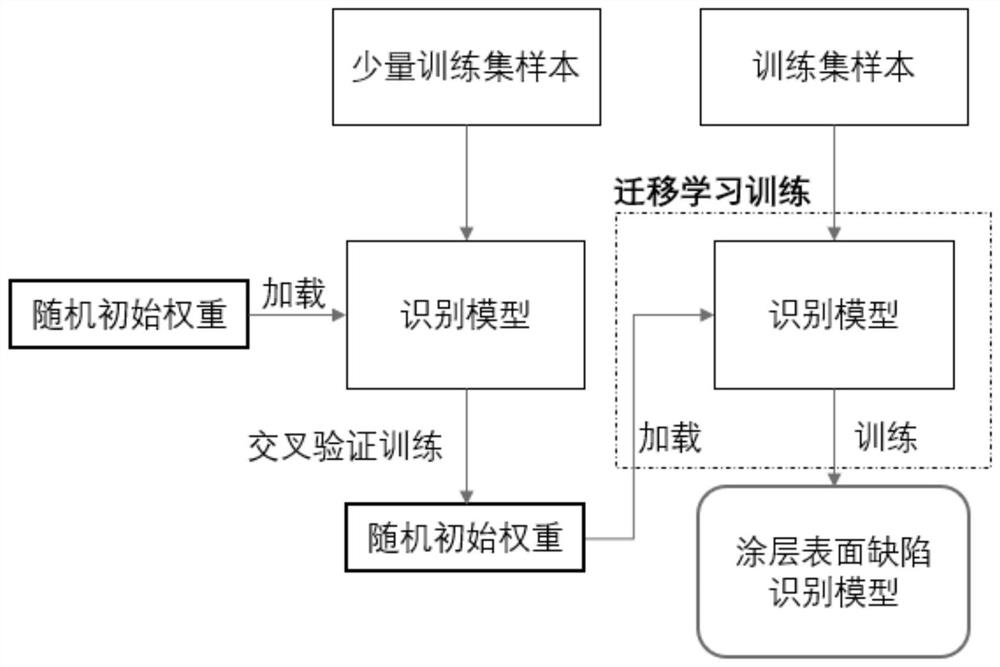

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0035] The present disclosure is capable of various embodiments, and adaptations and changes may be made therein. It should be understood, however, that there is no intention to limit the various embodiments of the present disclosure to the specific embodiments disclosed herein. Rather, the present disclosure should be understood to cover all modifications, equivalents, and / or alternatives falling within the spirit and scope of the various embodiments of the present disclosure.

[0036] The terminology used in the various embodiments of the present disclosure is for the purpose of describing particular embodiments only and is not intended to limit the various embodiments of the present disclosure. As used herein, the singular is intended to include the plural as well, unless the context clearly dictates otherwise. Unless otherwise def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com