Rubber tire cord fabric

A technology of rubber tires and cord fabrics, applied in special tires, tire parts, warp knitting, etc., can solve the problems of rubber losing elasticity, affecting safety, and not being able to effectively dissipate heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object of the present invention, the present invention will be further described below with reference to the accompanying drawings and examples below:

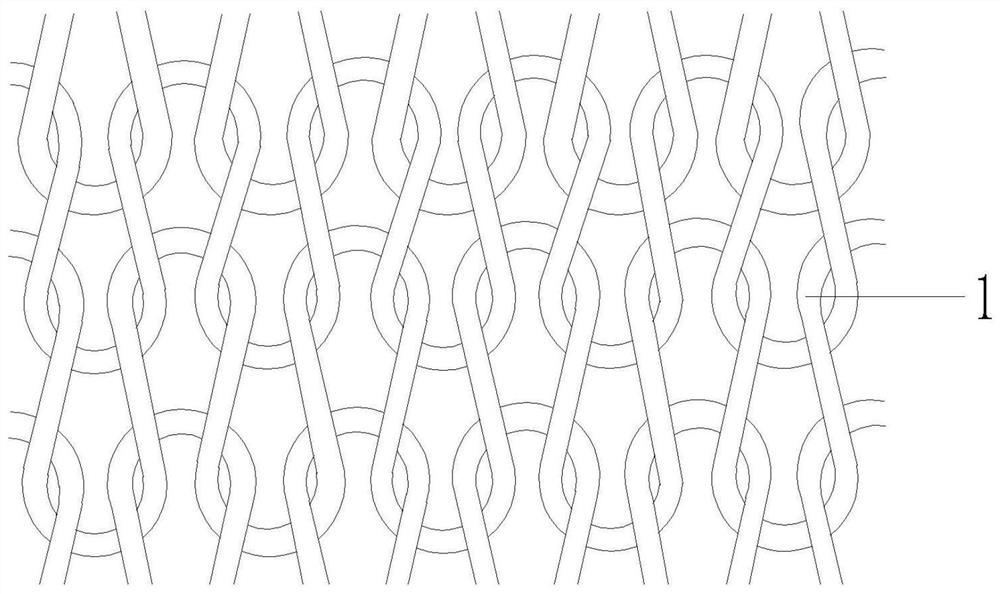

[0014] A rubber tire curtain fabric comprising yarn 1, which is woven from several of the yarns; the yarn is a high-mode low-shrinkage; several of the yarns have a certain elastic knitted knitted knit Woven fabric.

[0015] Preferably, if figure 1 In the case, several of the yarns form a weft fabric.

[0016] Preferably, several of the yarns form a braid (not shown in the figure).

[0017] Preferably, the yarn is a monofilament of 0.05 to 0.5 mm, or a multilayer that is twisted for a plurality of monofilaments of 0.05-0.5 mm, or a wire bundle formed of a plurality of squares of 0.006-0.1 mm.

[0018] Preferably, the yarn is a glass fiber, or is a basalt fiber, or is carbon fiber, or a aramid fiber, or a steel fiber, or a steel wire, or a copper alloy, or a polyester wire, Or is nylon.

[0019] When manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com