Automobile accessory box

An auto parts and box technology, applied in the field of auto parts and auto repair, can solve the problems of brittleness, corrosion, loss of sliding function of rubber slide rails and rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

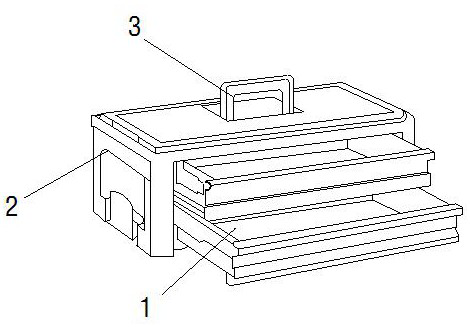

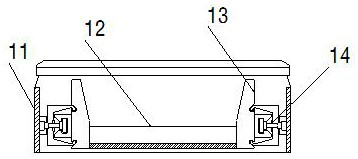

[0024] as attached figure 1 to attach Figure 4 Shown:

[0025] The present invention provides an auto parts box, the structure of which includes a storage layer 1, a box body 2, and a handle 3. The storage layer 1 is inlaid and mounted on the inner end surface of the box body 2, and the upper end of the box body 2 is movable at the center. The handle 3 is snap-connected, and the handle 3 is located in the storage layer 1: the storage layer 1 includes an inlay block 11, a placement table 12, a protective plate 13, and a sliding mechanism 14, and the inlay block 11 is embedded and installed in the storage layer. The inner end surface of the material layer 1 is attached to the sliding mechanism 14. The left and right sides of the placement table 12 are embedded with the protective plate 13, and the outer end surface of the protective plate 13 is embedded and connected with the sliding mechanism 14. The sliding mechanism 14 is provided with two and symmetrically installed on th...

Embodiment 2

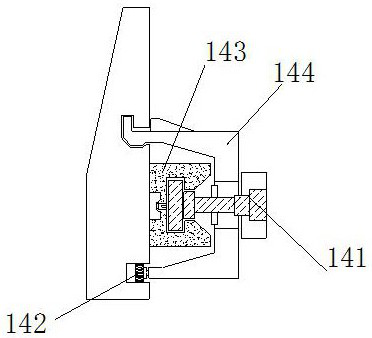

[0031] as attached Figure 5 to attach Figure 7 As shown: the embedded block 141 includes a supporting mechanism 1a, a connecting block 1b, an inlaying tooth 1c, and a supporting ring 1d. The supporting mechanism 1a is embedded and installed on the left end surface of the connecting block 1b. 1d is directly to the right, and is connected with the mosaic block 11. The mosaic teeth 1c are located on the left side of the support ring 1d, and are inlaid and engaged with the left end of the support mechanism 1a. The support ring 1d is movably mounted on the support On the outer end face of the mechanism 1a, the diameter of the outer ring of the support ring 1d is slightly smaller than the diameter of the inner end of the rubber slide rail 143. When the rubber slide rail 143 is squeezed or shrunk, the support ring 1d can be used as a supporting force to maintain its shape.

[0032] Wherein, the support mechanism 1a includes a shaft center 1a1, a short transverse pinion shaft 1a2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com