Magnesium-based composite material and preparation method thereof

A composite material and magnesium alloy technology, which is applied in the preparation and application of non-ferrous metal materials, can solve problems such as poor mechanical properties and decreased mechanical properties, and achieve the effects of good wear resistance, high hardness and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

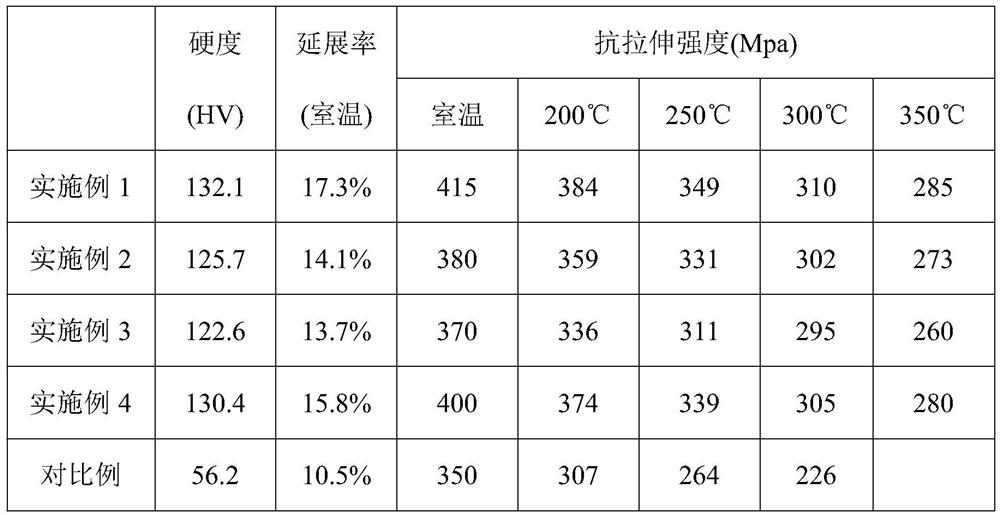

Examples

Embodiment 1

[0016] A preparation method of magnesium-based composite material:

[0017] (1) According to the molar ratio of 9:1, Al 2 o 3 and B 2 o 3 Mixed and ball milled in a ball mill for 8 hours, the ball mill speed was 300r / m, and the ball-to-material ratio (mass ratio) was 10:1 to obtain Al 18 B 4 o 33 Whisker preforms are available for use;

[0018] (2) Place the ZK60 magnesium alloy in a crucible furnace with gas shielding, heat up to 1100°C to melt and keep it warm, and the Al 18 B 4 o 33 The whisker preform is pressed into the ZK60 magnesium alloy melt through the graphite bell jar, Al 18 B 4 o 33 The mass ratio of the prefabricated body to the ZK60 magnesium alloy melt is 3:100, continue to stir and keep warm for 30 minutes, then cool the mixed melt to 720°C, and pour into shape after refining, degassing and slag removal;

[0019] (3) The magnesium-based composite material obtained in step (2) is subjected to T6 process treatment: solid solution at 530° C. for 6 hou...

Embodiment 2

[0021] A preparation method of magnesium-based composite material:

[0022] (1) According to the molar ratio of 7:3, Al 2 o 3 and B 2 o 3 Mix and mill in a ball mill for 9 hours, the ball mill speed is 300r / m, and the ball-to-material ratio (mass ratio) is 10:1 to obtain Al 18 B 4 o 33 Whisker preforms are available for use;

[0023] (2) Place the ZK60 magnesium alloy in a crucible furnace with gas shielding, heat up to 1200°C to melt and keep it warm, and the Al 18 B 4 o 33 The whisker preform is pressed into the ZK60 magnesium alloy melt through the graphite bell jar, Al 18 B 4 o 33 The mass ratio of the prefabricated body to the ZK60 magnesium alloy melt is 2:100, continue to stir and keep warm for 30 minutes, then cool the mixed melt to 740°C, and pour into shape after refining, degassing and slag removal;

[0024] (3) The magnesium-based composite material obtained in step (2) is subjected to T6 process treatment: solid solution at 530° C. for 6 hours, and agi...

Embodiment 3

[0026] A preparation method of magnesium-based composite material:

[0027] (1) According to the molar ratio of 9:3, Al 2 o 3 and B 2 o 3 Mixed and ball milled in a ball mill for 7h, the ball mill speed was 300r / m, and the ball-to-material ratio (mass ratio) was 10:1 to obtain Al 18 B 4 o 33 Whisker preforms are available for use;

[0028] (2) Place the ZK60 magnesium alloy in a crucible furnace with gas shielding, heat up to 1200°C to melt and keep it warm, and the Al 18 B 4 o 33 The whisker preform is pressed into the ZK60 magnesium alloy melt through the graphite bell jar, Al 18 B 4 o 33 The mass ratio of the prefabricated body to the ZK60 magnesium alloy melt is 5:100, continue to stir and keep warm for 30 minutes, then cool the mixed melt to 700°C, and pour into shape after refining, degassing and slag removal;

[0029] (3) The magnesium-based composite material obtained in step (2) is subjected to T6 process treatment: solid solution at 530° C. for 6 hours, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com