Briquette coal pellet cooling device and briquette coal production system

A production system and cooling device technology, applied in the fuel, solid fuel, petroleum industry and other directions, can solve the problems of increased briquettes smash rate, impact on output, large dust, etc., to reduce landing speed, increase output, reduce The effect of broken ball rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

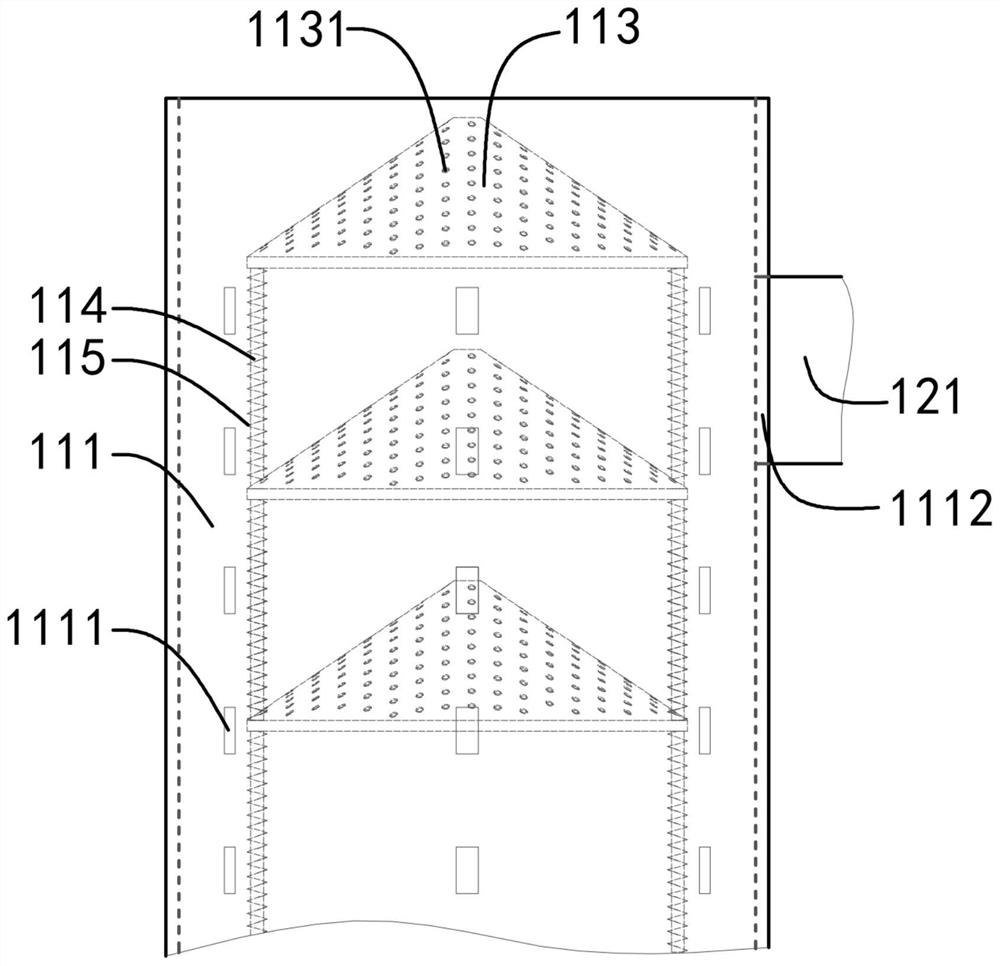

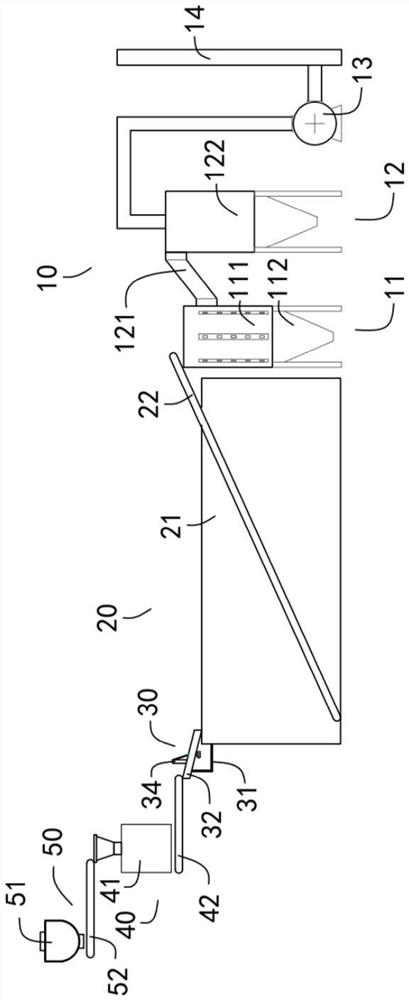

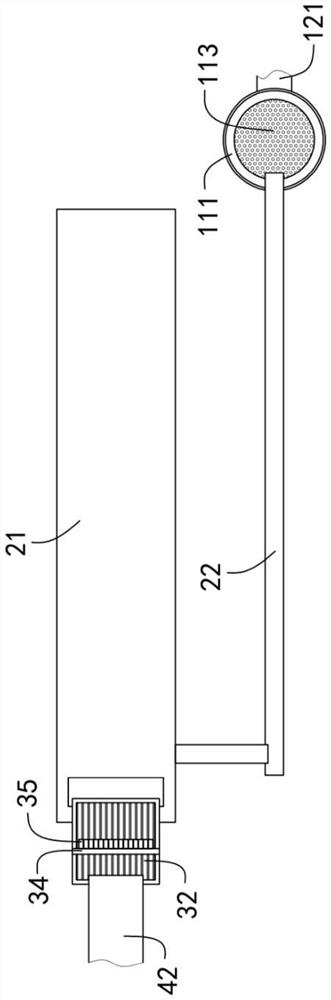

[0025] see Figure 1 to Figure 5 , the embodiment of the present invention provides a briquette pellet cooling device 10, including a cooling tower body 11, a cyclone dust collector 12, the cooling tower body 11 includes a storage bin 111, a discharge bin 112, a buffer umbrella 113, a storage bin 111 is a cylindrical barrel with openings at both ends. The discharge bin 112 is a hollow cone with an opening at the top. The buffer umbrella 113 is umbrella-shaped. The buffer umbrella 113 is densely covered with air holes 1131. A pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com