A kind of electric gradient distribution silicon carbide fiber reinforced ceramic matrix ultra-broadband wave-absorbing composite material and its preparation method

A silicon carbide fiber and fiber reinforced technology, which is applied in the field of high-gradient distribution silicon carbide fiber reinforced ceramic-based ultra-broadband wave absorbing composite material and its preparation, can solve the problem of poor interlayer performance and overall performance, and poor high-frequency wave absorbing performance. Obviously, the problems of low interlayer performance, etc., achieve the effects of good thermophysical matching, strong designability, and excellent absorbing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

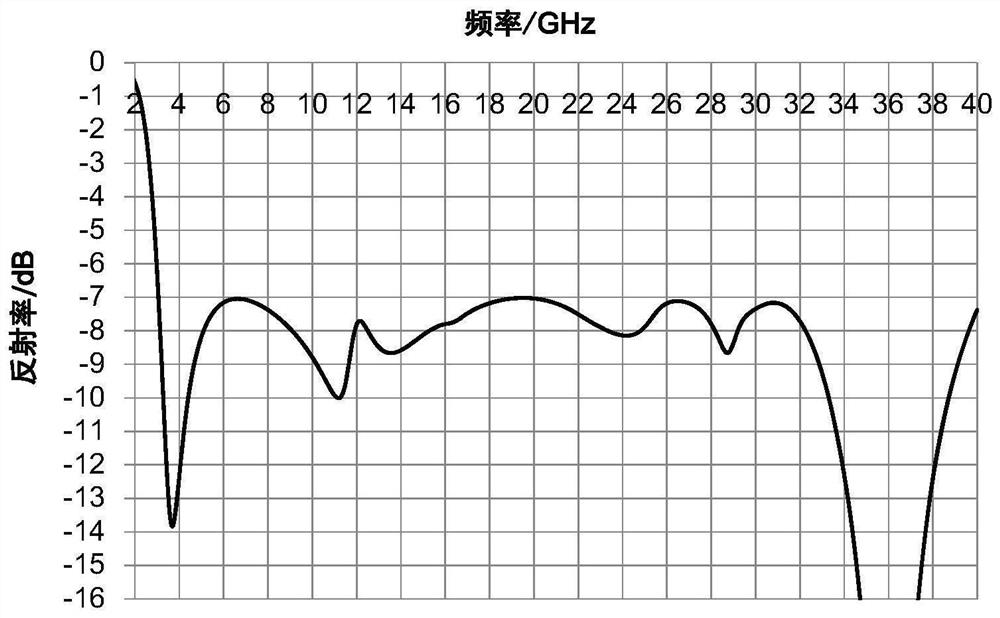

[0024] A silicon carbide fiber reinforced ceramic-based ultra-broadband wave-absorbing composite material with an elevator gradient distribution, starting from the incident direction of electromagnetic waves, sequentially comprises a first high-resistance silicon carbide fiber-reinforced ceramic-based composite material layer and a first lossy silicon carbide fiber array reinforced ceramics matrix composite material layer, second high resistance silicon carbide fiber reinforced ceramic matrix composite material layer, second lossy silicon carbide fiber array reinforced ceramic matrix composite material layer, third high resistance silicon carbide fiber reinforced ceramic matrix composite material layer, third A lossy silicon carbide fiber array reinforced ceramic matrix composite material layer and a fourth high resistance silicon carbide fiber reinforced ceramic matrix composite material layer. Among them, the resistivity of the silicon carbide fiber of the first, second, thir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com