Ultrathin unequal-thickness glass as well as production method and application thereof

A production method and ultra-thin glass technology, applied in the field of display screens, can solve problems such as wrinkles and excessive bending times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

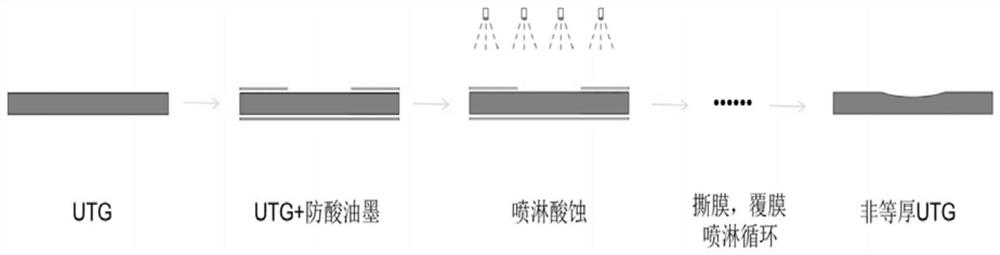

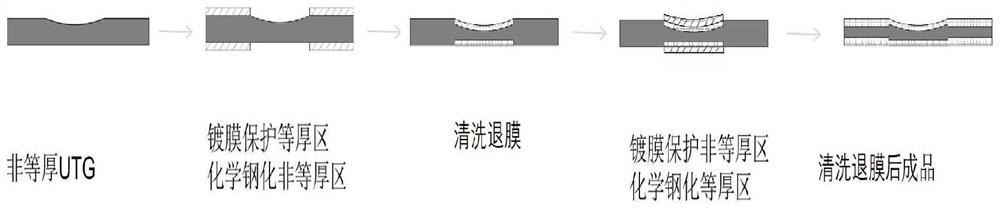

[0039] A method for producing ultra-thin non-equal-thickness glass, comprising the following steps:

[0040] 1) Acid etching the folding area of ultra-thin glass to reduce the thickness of the folding area:

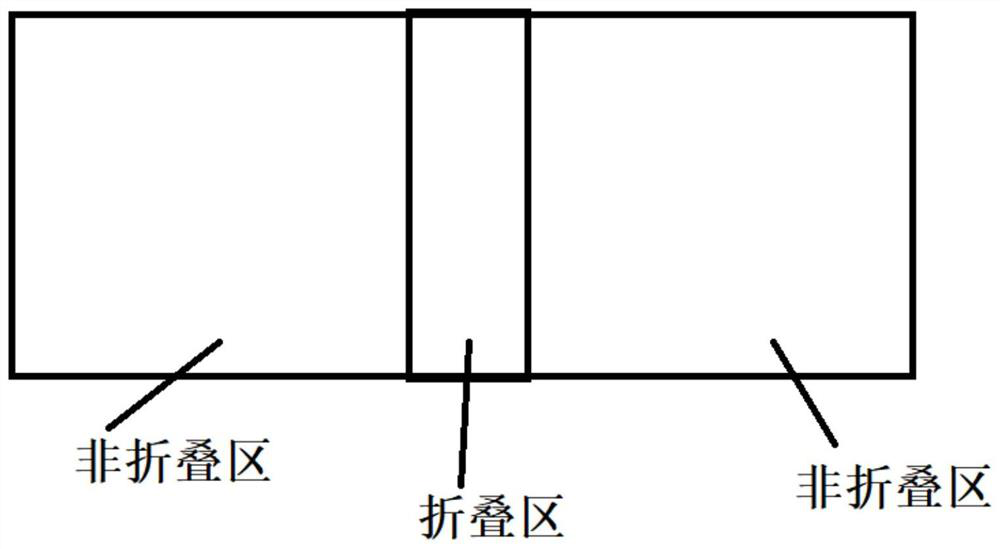

[0041] The size of the ultra-thin glass described in the patent of the present invention is between 70×70-200×200mm, and the thickness is 150-200μm. The 20-40mm wide area in the middle of one surface is the folding area. Except for this folding area, other areas of this surface It is a non-folding area, and the top view is as follows image 3 As shown; the other surface of the ultra-thin glass is the back, and the back and the non-folding area are covered with polyurethane UV film, and then the folding area is sprayed and etched. The temperature of the acid etching process is controlled at 30-40 ° C. The rate is controlled at 1-2μm / min, the spray flow rate is 400-600L / min, and after the first acid etching amount is 10-15μm, use 200-300mJ / cm 2 Ultraviolet light irradiat...

Embodiment 2

[0048] A method for producing ultra-thin non-equal-thickness glass, comprising the following steps:

[0049] 1) Acid etching the folding area of ultra-thin glass to reduce the thickness of the folding area:

[0050] The size of the ultra-thin glass described in the patent of the present invention is between 100×100 mm and the thickness is 150 μm. The 40 mm wide area in the middle of one surface is a folding area. Except for this folding area, other areas of this surface are non-folding areas. The top view is as follows: image 3 As shown; the other surface of the ultra-thin glass is the back, and the back and the non-folding area are covered with polyurethane UV film, and then the folding area is sprayed and etched. The temperature of the acid etching process is controlled at 35 ° C, and the etching rate is controlled At 1-2μm / min, the spray flow rate is 500L / min, and after the first acid etching amount is 15μm, use 200-300mJ / cm 2 Ultraviolet light irradiation, gently peelin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com