Volcanic drift rock glaze as well as preparation method and application thereof

A volcanic flow and volcano technology, applied in the field of glaze, volcanic flow rock effect glaze and its preparation, can solve the problems such as the inability to achieve the flow color effect, the inability to obtain the high brightness effect of the volcanic flow rock, etc., and achieves simple application method and high transparency. , high transparency and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

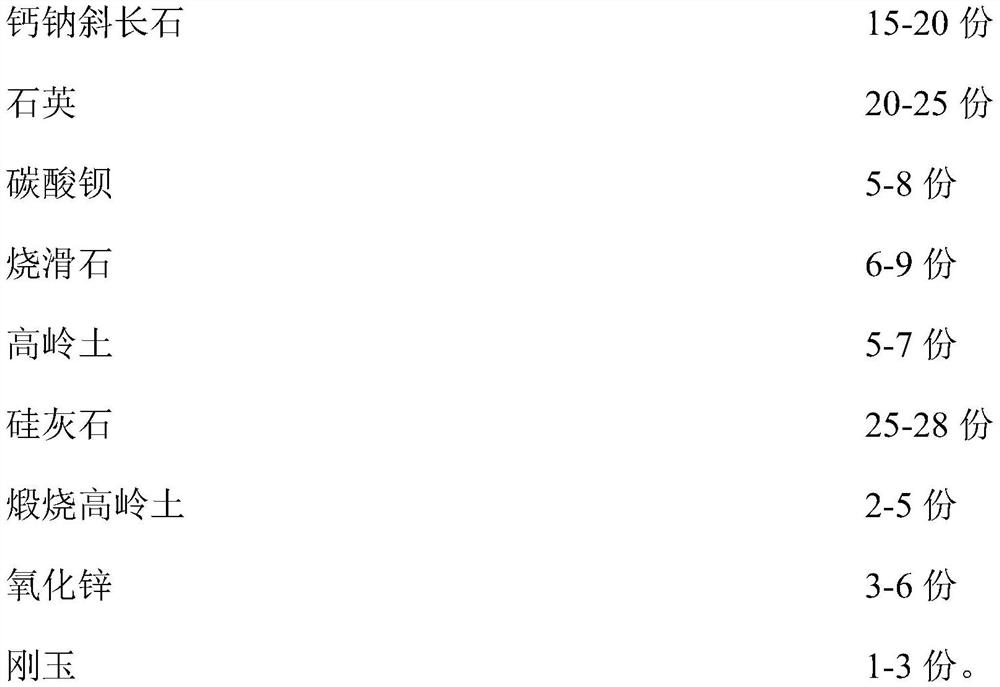

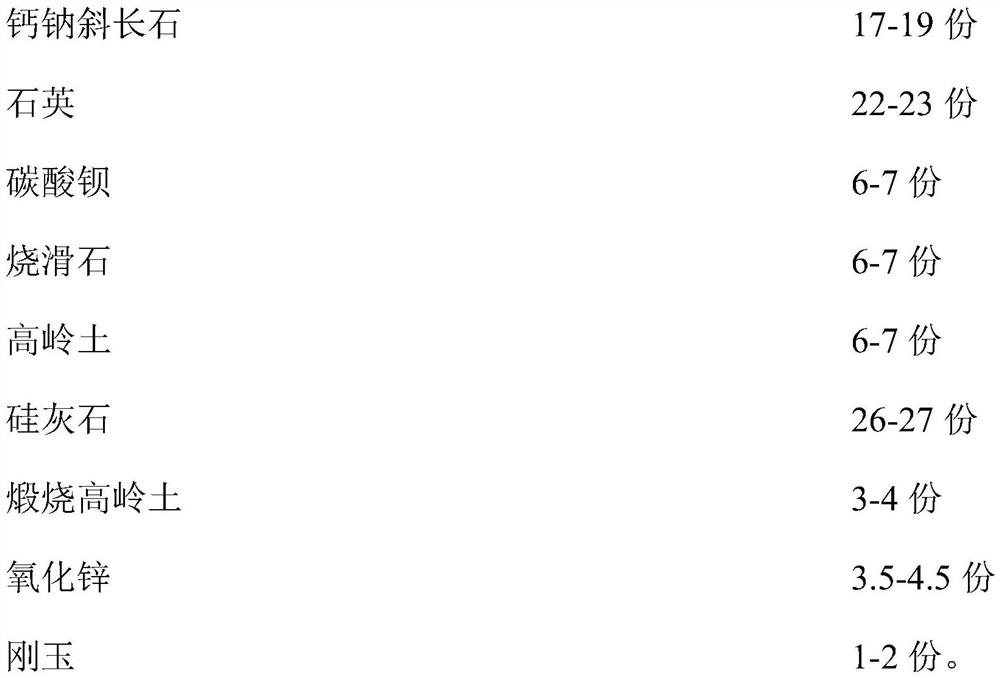

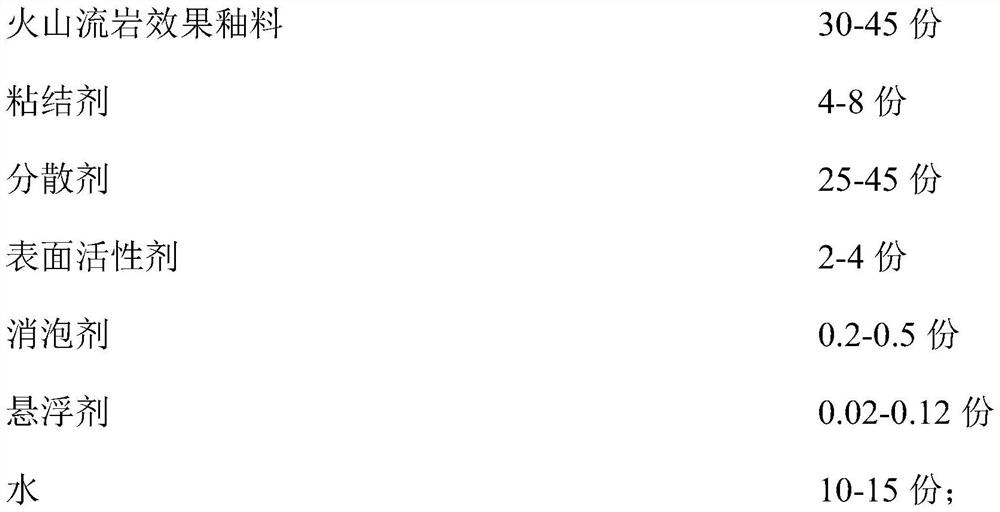

Method used

Image

Examples

Embodiment 1

[0091] This embodiment provides a method for preparing a volcanic flow rock effect glaze, the preparation method comprising the following steps:

[0092] (1) Mix raw materials by wet ball milling according to the formula amount, and use absolute ethanol to immerse the raw materials during wet ball milling to obtain a mixed material with an average particle size of 40 μm;

[0093](2) Dividing the mixed material obtained in step (1) into the first powder and the second powder, the mass ratio of the first powder and the second portion of material is 2:1; and the first powder and the second powder The two powders are subjected to wet ball milling respectively, and absolute ethanol is used to immerse the raw materials during wet ball milling; the average particle size of the first ball mill obtained from the first powder ball mill is 30 μm; the second ball mill obtained from the second powder ball mill The average particle size of the material is 15 μm;

[0094] (3) Uniformly mixi...

Embodiment 2

[0097] This embodiment provides a method for preparing a volcanic flow rock effect glaze, the preparation method comprising the following steps:

[0098] (1) Mix raw materials by wet ball milling according to the formula amount, and use absolute ethanol to immerse the raw materials during wet ball milling to obtain a mixed material with an average particle size of 30 μm;

[0099] (2) Dividing the mixed material obtained in step (1) into the first powder and the second powder, the mass ratio of the first powder and the second portion of material is 3:1; and the first powder and the second powder The two powders are subjected to wet ball milling respectively, and absolute ethanol is used to immerse the raw materials during wet ball milling; the average particle size of the first ball mill obtained from the first powder ball mill is 20 μm; the second ball mill obtained from the second powder ball mill The average particle size of the material is 10 μm;

[0100] (3) Uniformly mix...

Embodiment 3

[0103] This embodiment provides a method for preparing a volcanic flow rock effect glaze, the preparation method comprising the following steps:

[0104] (1) Mix raw materials by wet ball milling according to the formula amount, and use absolute ethanol to immerse the raw materials during wet ball milling to obtain a mixed material with an average particle size of 50 μm;

[0105] (2) Dividing the mixed material obtained in step (1) into the first powder and the second powder, the mass ratio of the first powder and the second portion is 1:1; and the first powder and the second powder The two powders are subjected to wet ball milling respectively, and absolute ethanol is used to immerse the raw materials during wet ball milling; the average particle size of the first ball mill obtained from the first powder ball mill is 40 μm; the second ball mill obtained from the second powder ball mill The average particle size of the material is 20 μm;

[0106] (3) Uniformly mixing the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com