Novel anti-seepage paper cup

A paper cup, a new type of technology, applied in the field of paper cups, can solve the problems of unreliable anti-seepage performance of the coating layer, easy softening of paper cups, and difficulty in use, etc., to achieve stable and reliable anti-seepage performance, convenient handling and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

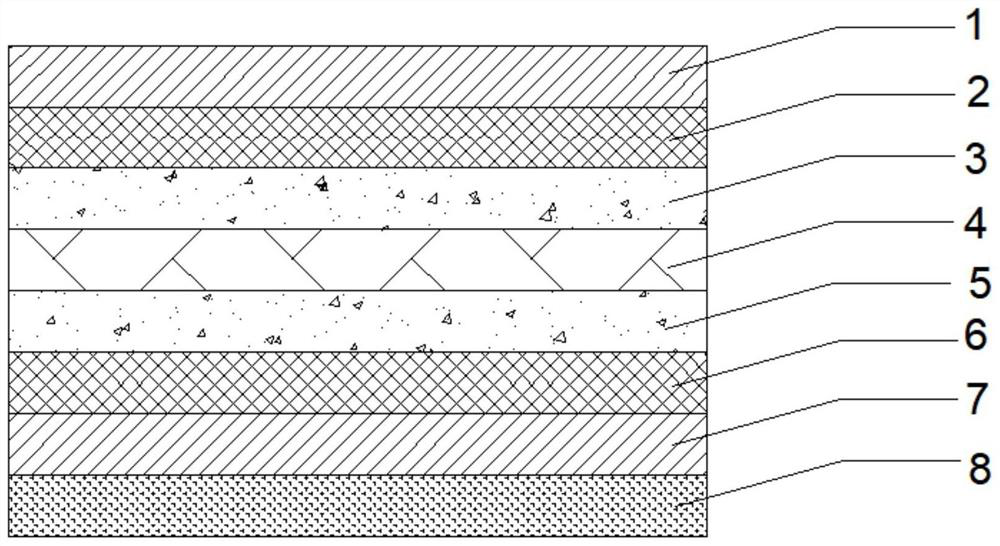

[0026] Reference attached figure 1 , a new anti-seepage paper cup, including a first waterproof layer 1, a first heat insulation layer 2, a first reinforcement layer 3, a fan-shaped paper sheet 4, a second reinforcement layer 5, a second heat insulation layer 6, a second waterproof layer 7 and printing layer 8, the first waterproof layer 1, the first heat insulation layer 2, the first reinforcement layer 3, the fan-shaped paper sheet 4, the second reinforcement layer 5, the second heat insulation layer 6, and the second waterproof layer 7 and the printing layer 8 are sequentially stacked from the inside to the outside, and the first reinforcement layer 3 and the second reinforcement layer 5 are a polymer layer formed by bonding two layers of polymer materials and a fabric layer evenly arranged in the polymer layer, so The fabric layer is woven from warps and wefts, the warps are cotton fibers, the wefts are blended polylactic acid fiber yarns and cotton fibers, and the polymer...

Embodiment 2

[0036] A new anti-seepage paper cup, including a first waterproof layer 1, a first heat insulation layer 2, a first reinforcement layer 3, a fan-shaped paper sheet 4, a second reinforcement layer 5, a second heat insulation layer 6, and a second waterproof layer 7 And the printing layer 8, the first waterproof layer 1, the first heat insulation layer 2, the first reinforcement layer 3, the fan-shaped paper sheet 4, the second reinforcement layer 5, the second heat insulation layer 6, the second waterproof layer 7 and The printing layer 8 is stacked sequentially from the inside to the outside. The first reinforcement layer 3 and the second reinforcement layer 5 are a polymer layer formed by bonding two layers of polymer materials and a fabric layer evenly arranged in the polymer layer. The fabric layer is woven from warps and wefts, the warps are cotton fibers, the wefts are polylactic acid fiber yarns blended with cotton fibers, and the polymer layer is a thermoplastic polyuret...

Embodiment 3

[0039] The paper cup paper made by the above method is formed on the paper cup forming equipment, and the formed paper cup is sterilized by high-temperature steam at 120-130°C, and the sterilized paper cup is sealed and packed in a plastic bag, and then packed into a carton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com