Novel vulcanization pressurizing plate, vulcanizer, rubber sheet for conveyor belt joint and conveyor belt connecting method

A pressurized plate and conveyor belt technology, applied in applications, household components, household appliances, etc., can solve problems that cannot be equal to vulcanization pressure, rubber extrusion, inconvenient vulcanization pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

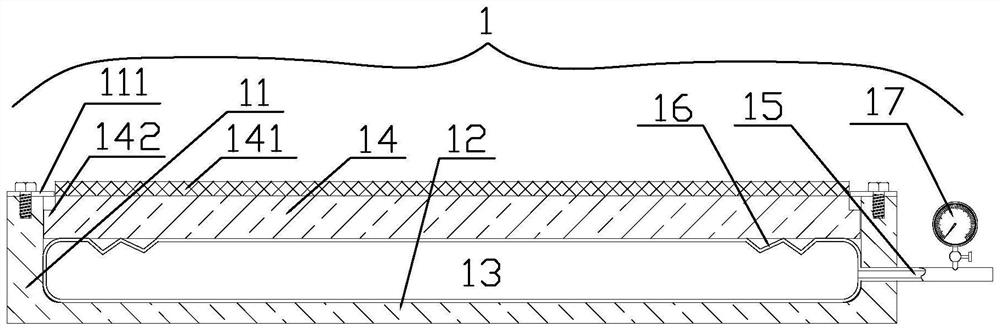

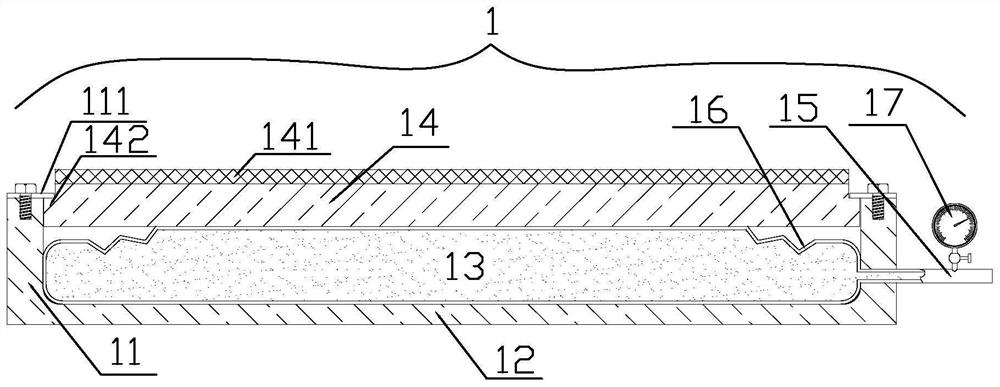

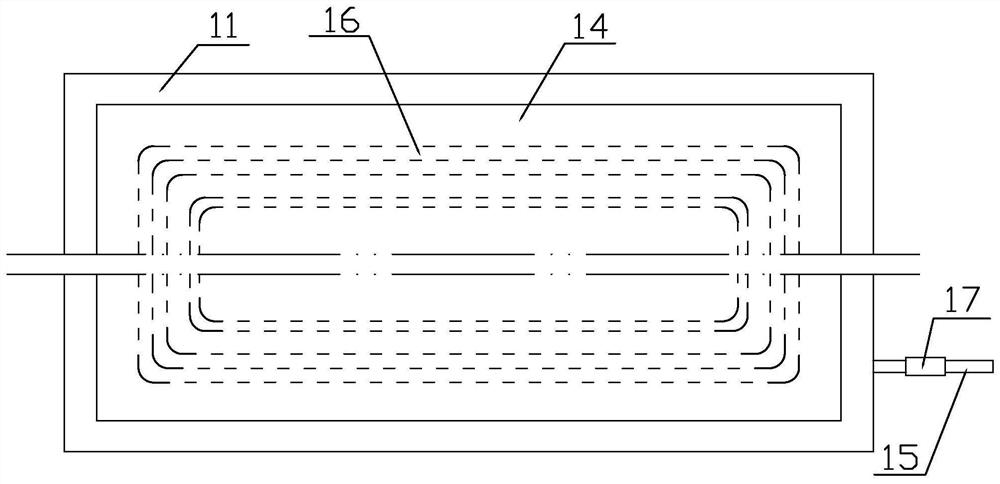

[0065] Implementation mode one: if Figure 1-4 As shown, the novel vulcanized pressurized plate 1 of the present invention comprises a square pressurized frame 11, a base plate 12, a stainless steel pressurized liner 13 and a lifting plate 14, and the base plate 12 is fixedly connected with the lower edge of the square pressurized frame 11 to form an open square pit, the stainless steel pressurized liner 13 is set in the square pit, the lower surface of the lifting plate 14 is pressed on the stainless steel pressurized liner 13, and the lower edge of the lifting plate 14 is embedded in the square pit. Pressure liner 13 is flat square, and stainless steel pressurization liner 13 side wall is also communicated with a pressurization tube 15, after this pressurization tube 15 outer ends pass through described square pressurization frame 11, and pass through valve (not shown in the figure) out) is connected with the matching high-pressure pump (not shown in the figure), and the top...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com