Industrialized prefabrication production line system and method for embossed airport assembled pavement slabs

A technology of production line and control method, which is applied in the direction of manufacturing tools, ceramic molding machines, climate change adaptation, etc., can solve problems such as unfavorable cost control, insufficient texture durability, and excessive surface laitance, so as to optimize the production process and increase density. Strength and strength, increased durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

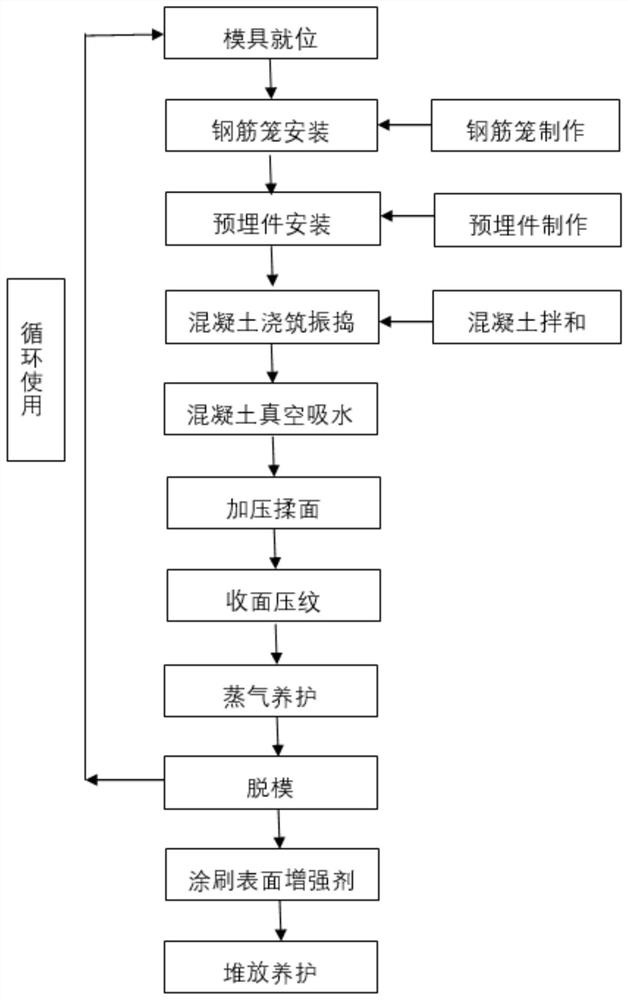

[0053] combine figure 1 , embossed airport assembly road panel factory prefabrication production line system and method, sequentially through the mold in place, steel cage installation, embedded parts installation, concrete pouring vibration, concrete vacuum water absorption, pressurized dough, surface embossing, Steam curing and panel demoulding realize the fast and safe processing of the assembled panel, and the precise processing and maintenance of the assembled panel can be realized by brushing and stacking maintenance on the panel surface.

[0054]The control method of the mold in place includes as follows: step A1, the prefabricated panel mold in the mold in place is processed and formed on a CNC machine tool with high-quality steel; step A2, using special lifting tools and equipment to complete the lifting and transportation of the prefabricated panel mold , to prevent deformation of the prefabricated panel mold.

[0055] In step A3, after the prefabricated panel mold ...

Embodiment 2

[0075] Embossed airport assembly road panel factory prefabrication production line system and method, sequentially through the mold in place, steel cage installation, embedded parts installation, concrete pouring vibration, concrete vacuum water absorption, pressurized dough, concrete surface and embossing , steam curing and panel demoulding to realize the fast and safe processing of the assembled panel, and to realize the precise processing and maintenance of the assembled panel by brushing and stacking the reinforcing agent on the surface of the panel. This system method effectively discharges the excess water in the concrete, makes the concrete more dense, improves the flexural and flexural tensile strength of the slab, and reduces the decrease in surface strength caused by vibration; the pressurized kneading process makes the concrete on the surface of the slab The density is better, which improves the durability of concrete; the embossing process is used to make the surfac...

Embodiment 3

[0077] combine figure 1 , Embossed airport assembly road panel factory prefabrication production line system and method, including mold in place, steel cage installation, embedded parts installation, concrete pouring vibration, concrete vacuum water absorption, pressurized dough kneading, surface embossing, steam Curing, demoulding, brushing surface enhancer, stacking and curing.

[0078] The mold positioning control method includes the following: the mold is processed and formed on a CNC machine tool with high-quality steel, the main body of the mold consists of a base, a bottom mold, a side formwork, and an end formwork, and the mold base is a welded integral steel structure bracket, which is a self-supporting system. It is cut and processed from the whole high-quality steel plate, and the four sides and the bottom are all welded by reinforced plates.

[0079] The installation accuracy of the surrounding formwork on the bottom plate is guaranteed by the positioning pins / hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com