Bearing machining and grinding method

A bearing processing and bearing technology, applied in the field of bearing processing, can solve the problems of excessive dust accumulation, damage to employees and equipment, affecting the grinding and fixing accuracy of equipment, etc., and achieve the effect of increasing the safety of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

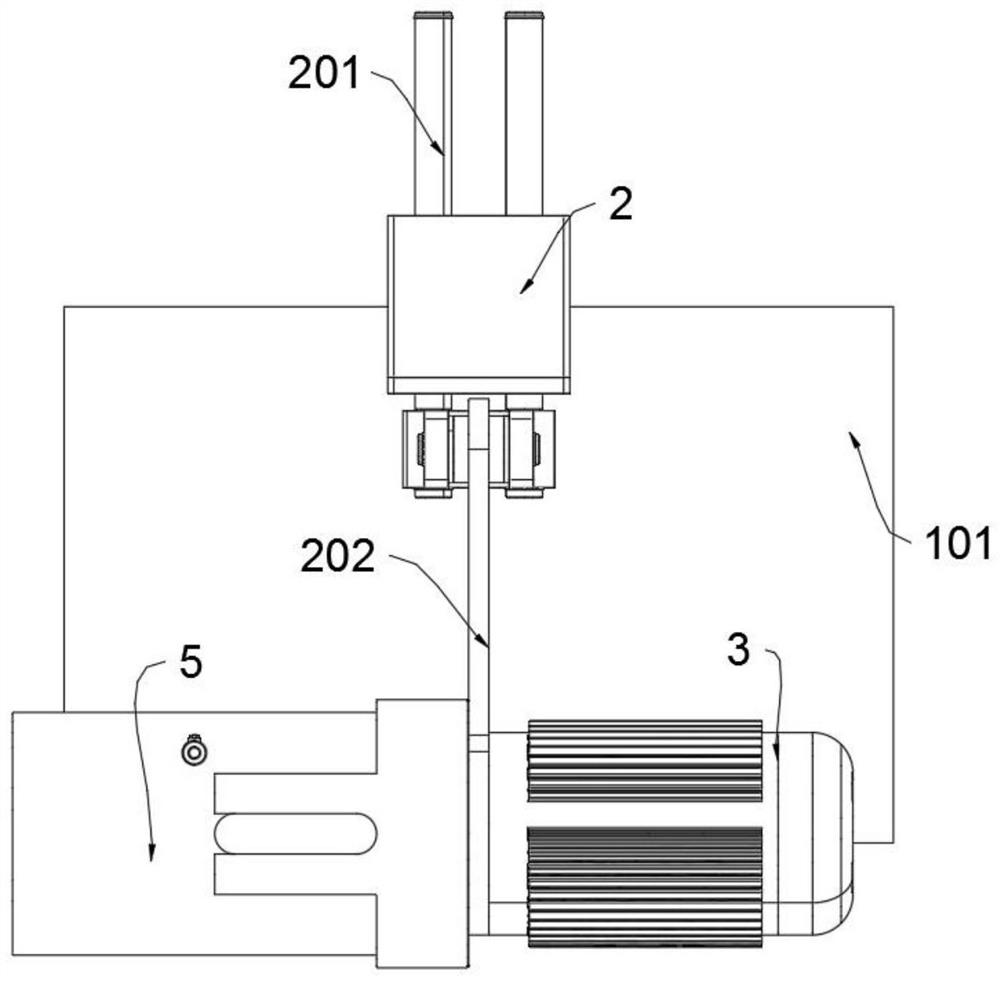

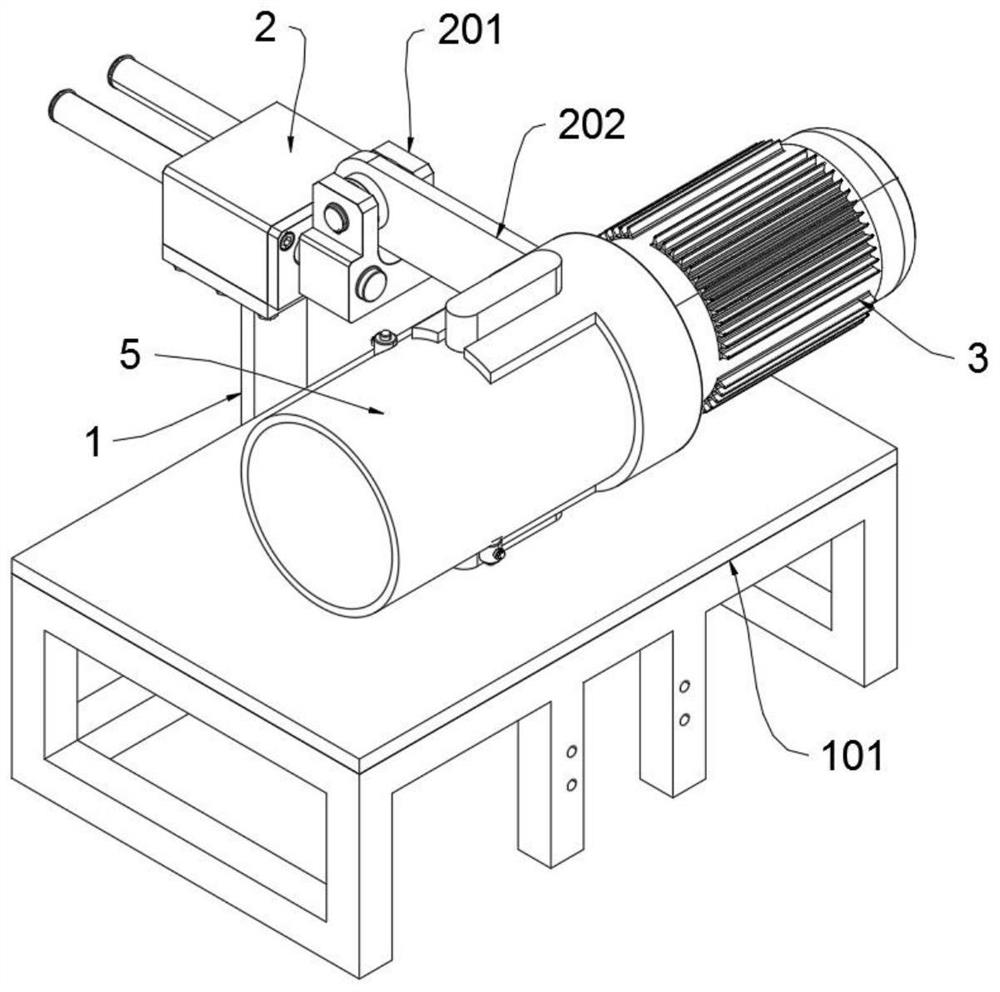

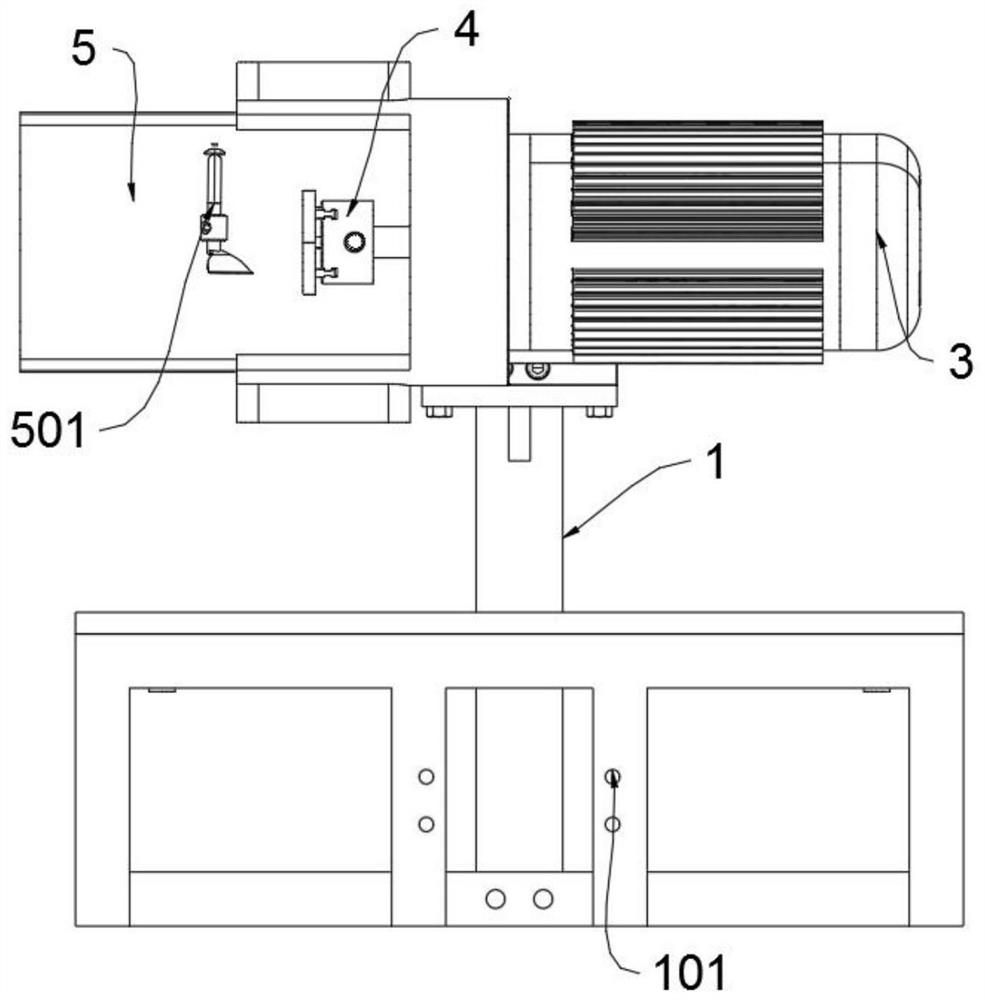

[0030] as attached figure 1 To attach Figure 8 Shown:

[0031] The present invention provides a bearing processing and grinding method. The bearing processing and grinding method uses a bearing processing and grinding device to complete the bearing processing and grinding device; the bearing processing and grinding device includes: a support mechanism 1; the top of the support mechanism 1 is in a square shape, The side of the support mechanism 1 is a T-shaped vertical rod, and the front and rear ends of the square plate of the support mechanism 1 are provided with triangular plates, and the front end of the lower position of the support mechanism 1 is provided with threaded holes. The top position of the support mechanism 1 and the bottom position of the extension mechanism 2 are fixed. Connection; the support mechanism 1 includes: a base 101, the base 101 is a rectangular shape, the top of the base 101 is a rectangular plane, the middle position of the rear end of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com