Preparation method of multi-component new alloy and component gradient alloy material part

A technology of alloy materials and composition gradients, which is applied in the field of additive manufacturing, can solve problems affecting the uniformity of formed parts, differences in mixed components, and severe material evaporation, so as to eliminate composition segregation, reduce the probability of forming defects, and improve material utilization. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a multi-component new alloy material piece, comprising the steps of:

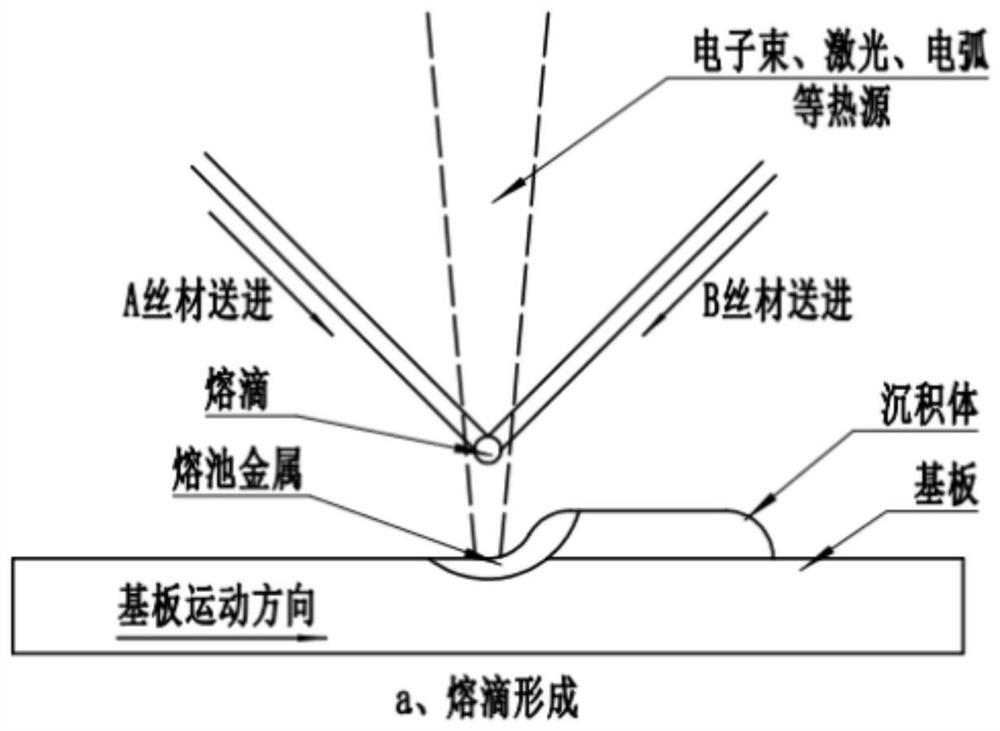

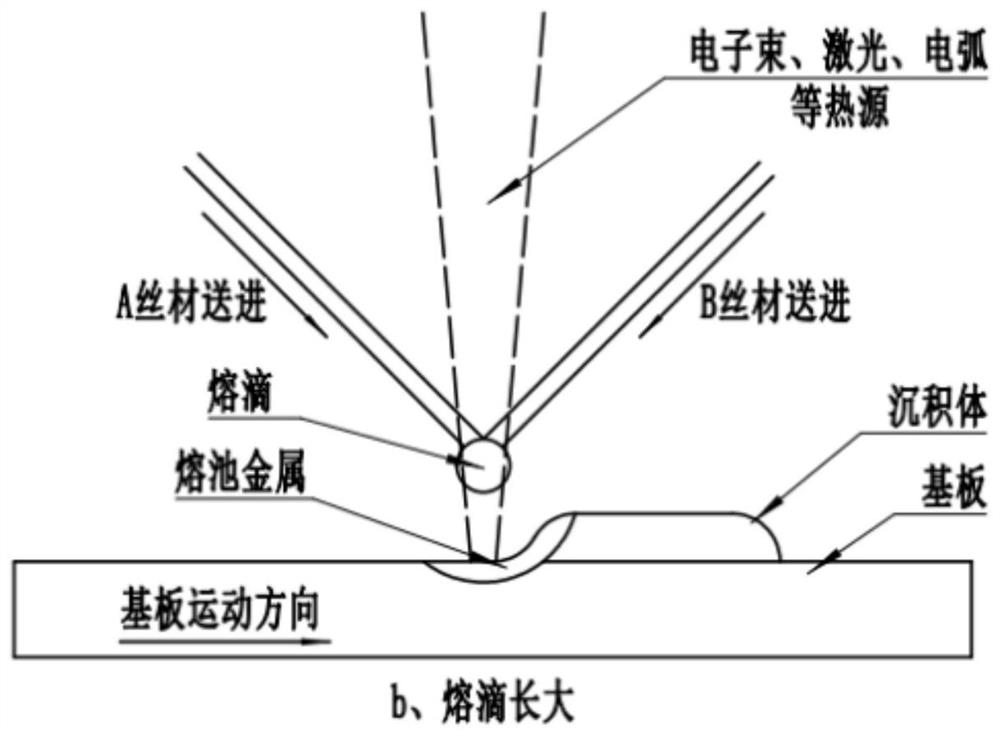

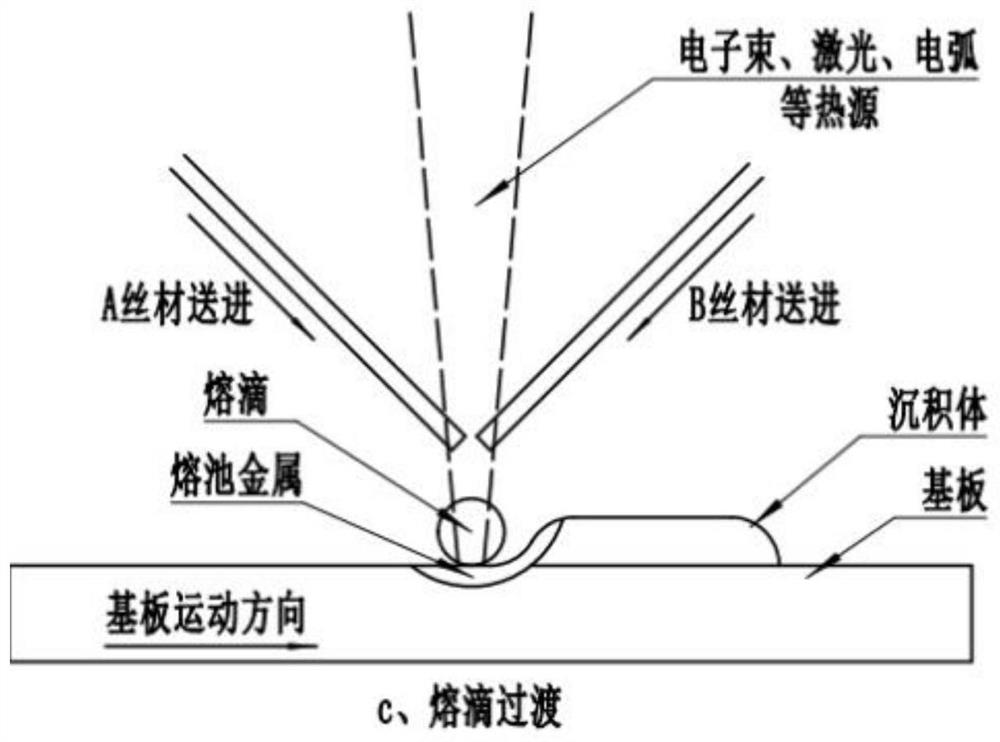

[0031] (1) Send two or more wires with different metal components into the fuse additive equipment at the same time, and form a molten pool on the substrate through a heat source;

[0032] (2) On the basis of the pre-composition group design and the analysis of the physical characteristics of various metal wires, by controlling the diameter range of different component wires, the distance between various wires, the distance between the wire and the substrate, and the The feed speed of the wire material is controlled by the parameter program of the forming process, so that the high melting point component wire is used as the main object of the heat source melting, and a molten drop is formed first, and is attached to the tip of the wire through surface tension, while a relatively low melting point is used. The tip of the wire material of the component contacts the droplet of the...

Embodiment 2

[0039] (1) Install the aluminum wire, titanium wire and niobium wire in the three wire feeding channels of the additive manufacturing machine, and adjust the phase relationship of the three wires so that the aluminum wire is placed at the bottom and the niobium wire is placed at the top. The titanium wire is placed between the aluminum wire and the niobium wire, and the distance between the aluminum wire and the titanium wire and between the titanium wire and the niobium wire does not exceed the diameter of the wire;

[0040] (2) Install the titanium alloy substrate, adjust the height of the substrate so that the distance between the end of the lowest aluminum wire and the substrate is 2-5 times the diameter of the wire;

[0041] (3) When the vacuum reaches the set value, electrons are emitted from the electron gun to irradiate the titanium substrate to form a local molten pool;

[0042] (4) Feed niobium wire, titanium wire and aluminum wire at the same time. The feeding speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com