A kind of preparation method and application of polymer-containing nanowire composite film material

A composite thin film and nanowire technology, applied in structural parts, secondary battery repair/maintenance, electrical components, etc., can solve problems such as reducing the cycle stability of solid-state batteries, achieve short synthesis time, improve transmission efficiency, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

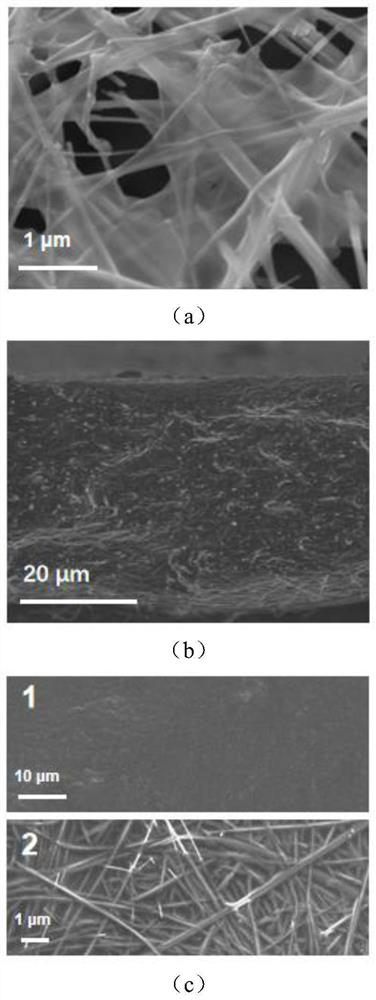

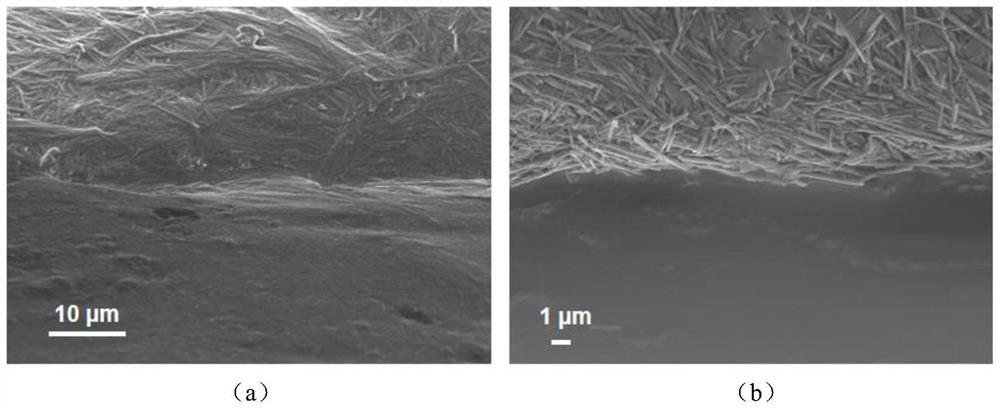

[0054] A polymer-containing nanowire composite thin film material, which sequentially includes a polymer layer, a composite layer and a functional interface layer from top to bottom, and the thickness of the polymer-containing nanowire composite thin film material is 35 μm.

[0055] in,

[0056] The composite layer includes a framework structure composed of graphene and nanowires, and the voids of the framework structure are filled with polymers;

[0057] The functional interface layer is composed of a framework structure composed of graphene and nanowires.

[0058] The content of polyethylene oxide in the composite layer is 40wt% of the composite layer; the thickness is 25 μm;

[0059] The nanowires have a diameter of 100 mm and a length of 5 μm.

[0060] The preparation method of the above-mentioned polymer-containing nanowire composite thin film material comprises the following steps:

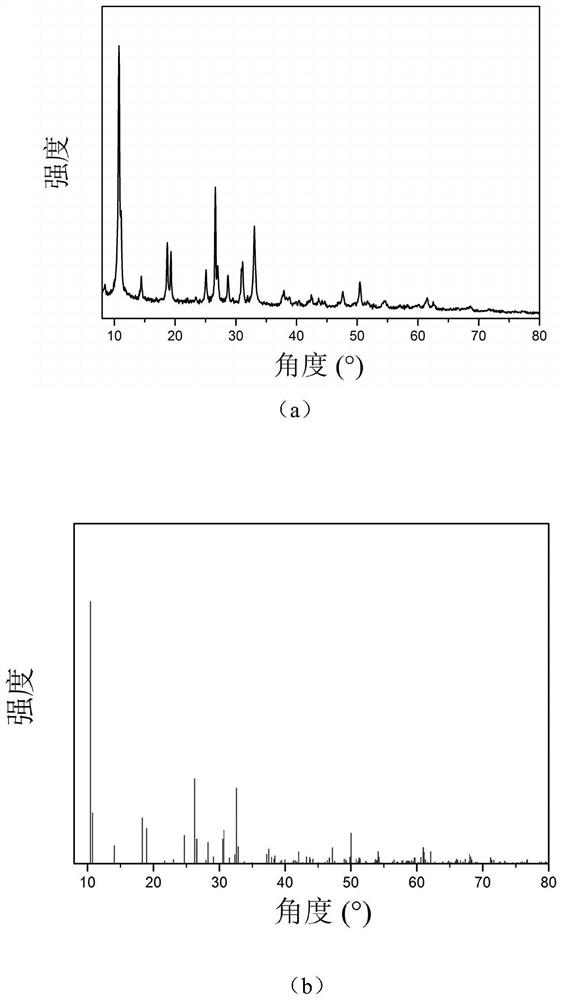

[0061] S1. the composite material (graphene accounts for 3wt% of composite material) ...

Embodiment 2

[0073] A polymer-containing nanowire composite thin film material, which sequentially includes a polymer layer, a composite layer and a functional interface layer from top to bottom, and the thickness of the polymer-containing nanowire composite thin film material is 37 μm.

[0074] in,

[0075] The composite layer includes a framework structure composed of graphene and nanowires, and the voids of the framework structure are filled with polymers;

[0076] The functional interface layer is composed of a framework structure composed of graphene and nanowires.

[0077] The content of polyethylene oxide in the composite layer is 45wt% of the composite layer; the thickness is 30 μm;

[0078] The nanowires have a diameter of 150 mm and a length of 6 μm.

[0079] The preparation method of the above-mentioned polymer-containing nanowire composite thin film material comprises the following steps:

[0080] S1. the composite material (graphene accounts for 3wt% of composite material) ...

Embodiment 3

[0084] A polymer-containing nanowire composite film material, which sequentially includes a polymer layer, a composite layer and a functional interface layer from top to bottom, and the thickness of the polymer-containing nanowire composite film material is 40 μm.

[0085] in,

[0086] The composite layer includes a framework structure composed of graphene and nanowires, and the voids of the framework structure are filled with polymers;

[0087] The functional interface layer is composed of a framework structure composed of graphene and nanowires.

[0088] The content of polyethylene oxide in the composite layer is 50wt% of the composite layer; the thickness is 35 μm;

[0089] The nanowires have a diameter of 170 mm and a length of 8 μm.

[0090] The preparation method of the above-mentioned polymer-containing nanowire composite thin film material comprises the following steps:

[0091] S1. the composite material (graphene accounts for 3wt% of composite material) of the nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com