Preparation method and application of self-supporting catalytic electrode

A catalytic electrode, self-supporting technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor process reliability, many preparation steps, and many types of chemicals, so as to achieve no pollutant emission, simple preparation process, and raw materials. Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare a self-supporting catalytic electrode as follows:

[0038] (1) The ferronickel foam with a mass ratio of nickel to iron of 5:5 was ultrasonically cleaned with an aqueous solution of hydrochloric acid at a concentration of 2 mol / L for 30 minutes to obtain the ferronickel foam after treatment.

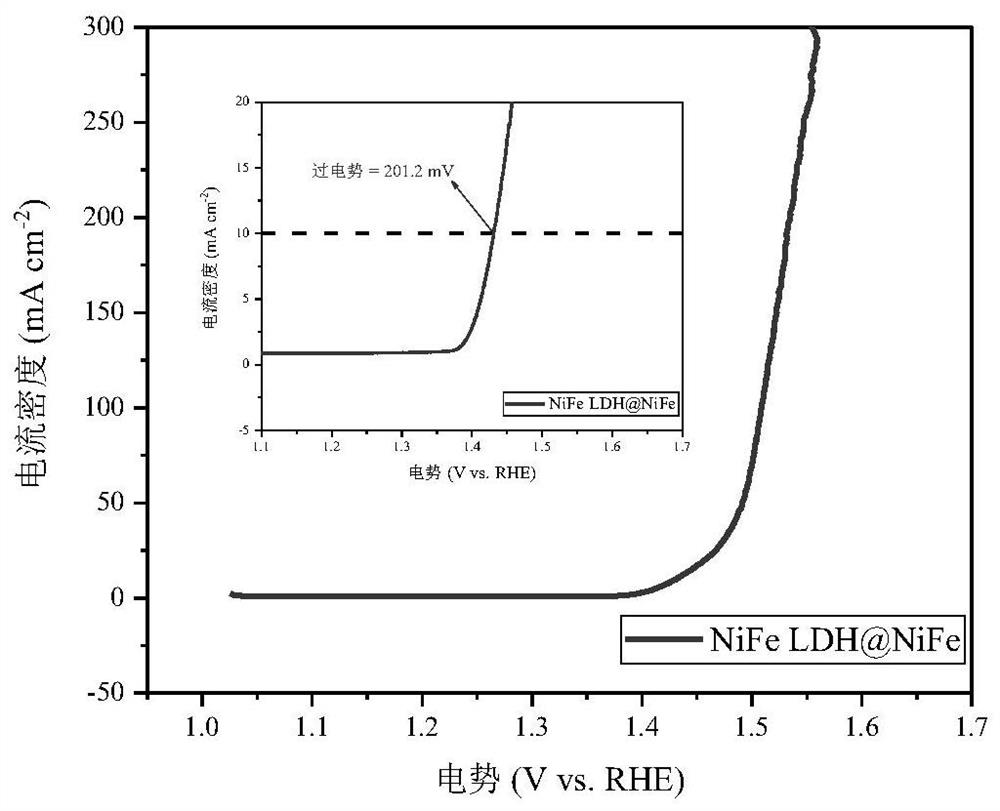

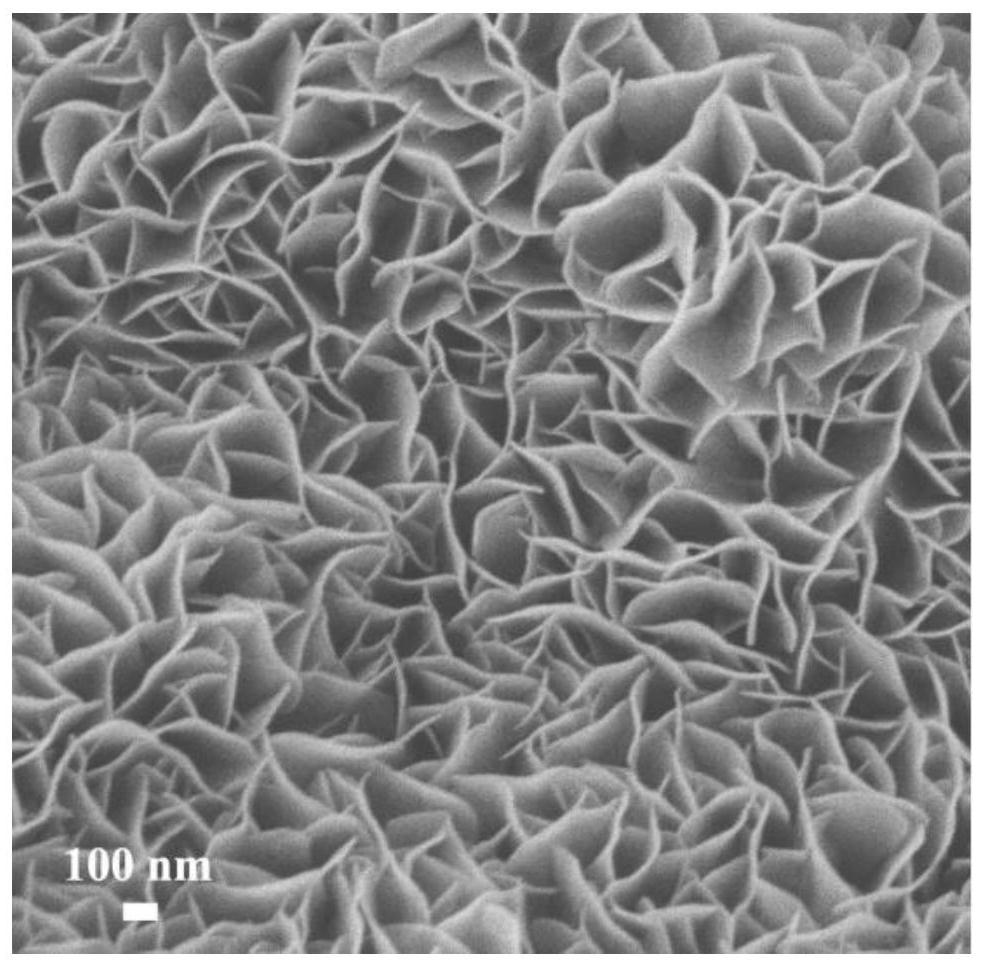

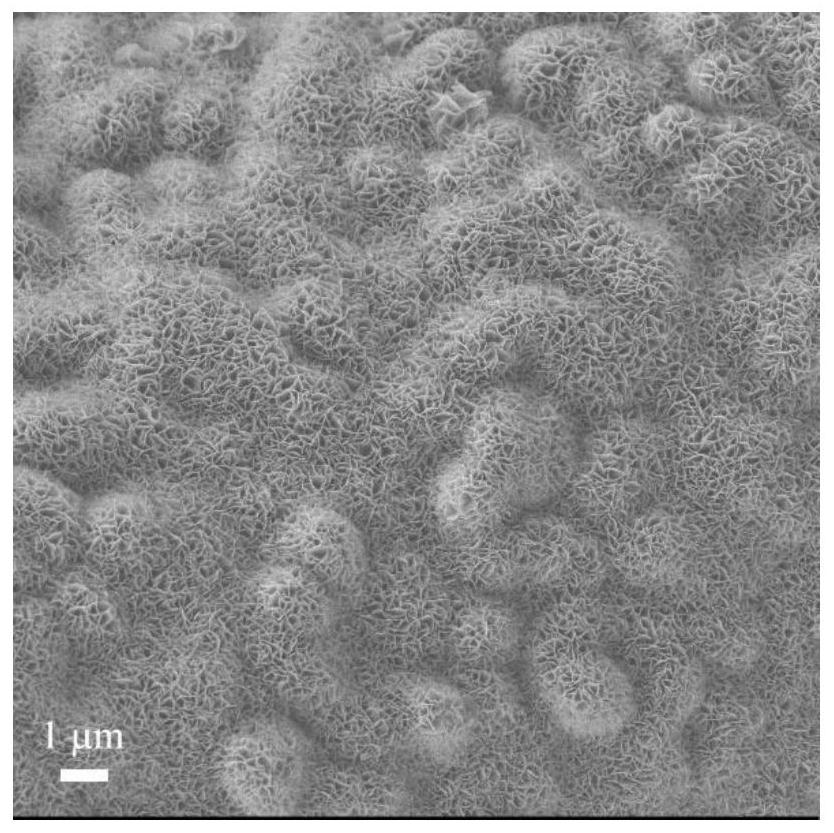

[0039] (2) preparation volume fraction is the ethylene glycol aqueous solution of 98%, mixes after adding the concentrated sulfuric acid wherein, the concentration of sulfuric acid in the solution reaches 2mol / L, obtains the sulfuric acid aqueous solution that contains ethylene glycol; Step (1) gained processing The final foamed nickel-iron was immersed in the sulfuric acid aqueous solution containing ethylene glycol for 15 hours, then cleaned with deionized water, and dried in the air to obtain a self-supporting catalytic electrode of nickel-iron layered double metal hydroxide loaded on nickel-iron alloy , recorded as nickel iron hydroxide / nickel iron catalytic electrod...

Embodiment 2

[0048] Prepare a self-supporting catalytic electrode as follows:

[0049] (1) Take nickel-iron foam with a mass ratio of nickel to iron of 5:5, and use 2mol / L concentration of aqueous hydrochloric acid to ultrasonically clean it for 30 minutes to obtain treated foam nickel-iron.

[0050] (2) preparation volume fraction is the ethylene glycol aqueous solution of 98%, after adding concentrated sulfuric acid therein, mix evenly, the concentration of sulfuric acid in the solution reaches 1mol / L, 2mol / L, 5mol / L respectively, obtains containing ethylene glycol different Aqueous solution of sulfuric acid concentration; the ferronickel foam after the treatment obtained in step (1) was immersed in the sulfuric acid aqueous solution containing ethylene glycol for 15 hours, then after cleaning with deionized water, air-dried to obtain a self-supporting catalytic electrode.

[0051] The self-supporting catalytic electrode prepared by the aqueous solution of different sulfuric acid concent...

Embodiment 3

[0053] Prepare a self-supporting catalytic electrode as follows:

[0054] (1) Get nickel-iron foam with a mass ratio of nickel to iron of 5:5, and use 2mol / L concentration of aqueous hydrochloric acid to ultrasonically clean it for 30 minutes to obtain treated foam nickel-iron.

[0055] (2) preparation volume fraction is the ethylene glycol aqueous solution of 98%, mixes after adding the concentrated sulfuric acid wherein, the concentration of sulfuric acid in the solution reaches 2mol / L, obtains the aqueous solution of the different sulfuric acid concentration that contains ethylene glycol; Step (1 ) The foamed ferronickel after the resulting treatment is immersed in the sulfuric acid aqueous solution containing ethylene glycol for 5 hours, 10 hours, 15 hours, and 25 hours respectively, then after cleaning with deionized water, dry in air to obtain a self-supporting catalytic electrode.

[0056] The self-supporting catalytic electrode prepared from the aqueous solution of dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com