Array type inner supporting clamp for large spherical crown type thin-walled workpiece and flexible clamping method

A technology for internal support fixtures and thin-walled parts, applied in the direction of clamping devices, clamping, positioning devices, etc., can solve the problem of difficult adaptation, inability to fit the inner surface of parts closely, and the array of large-scale spherical crown thin-walled parts. Type inner support fixture and flexible clamping method and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

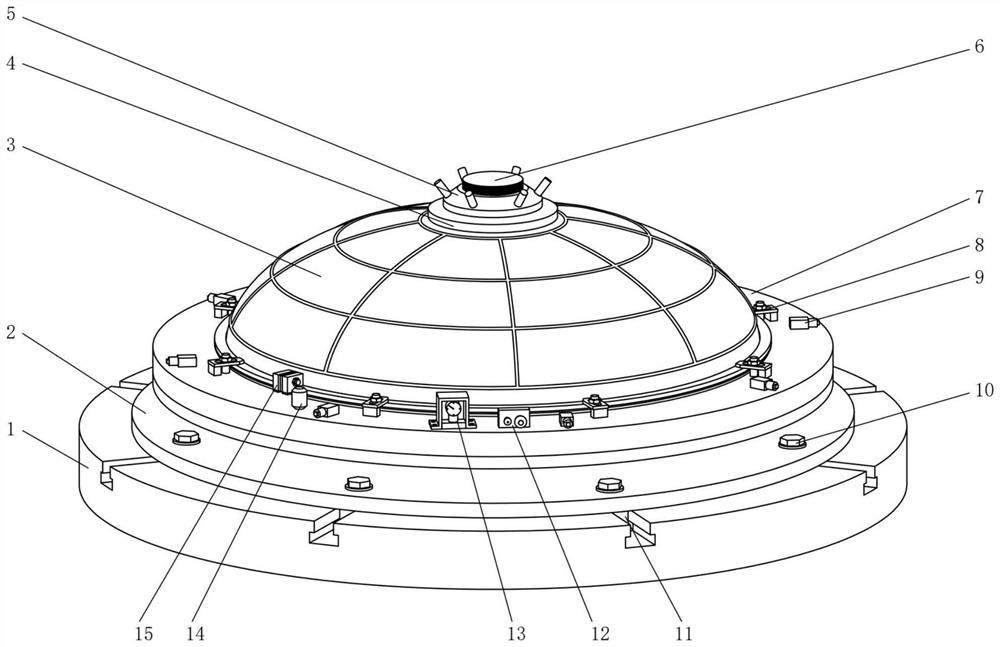

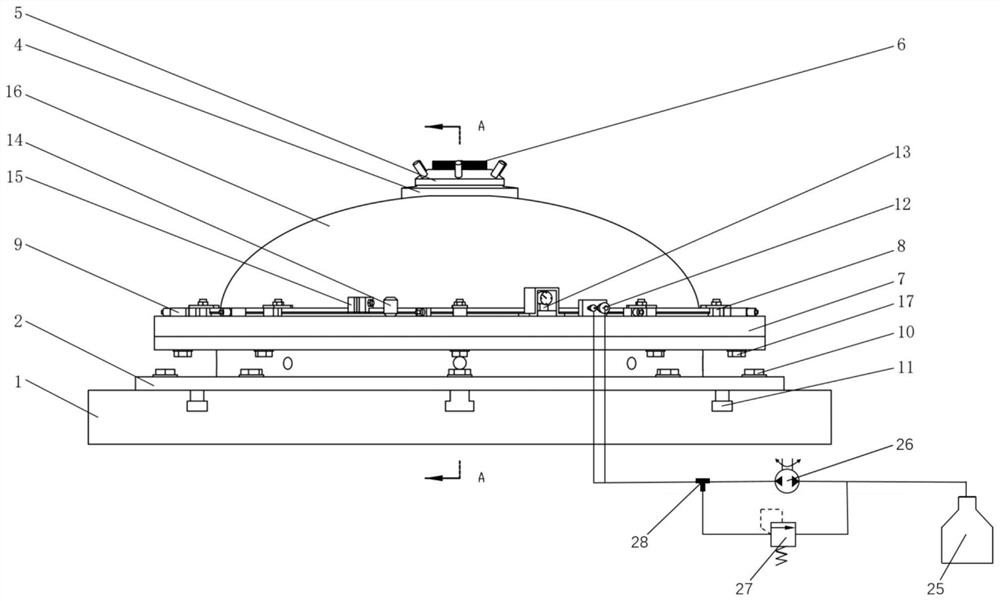

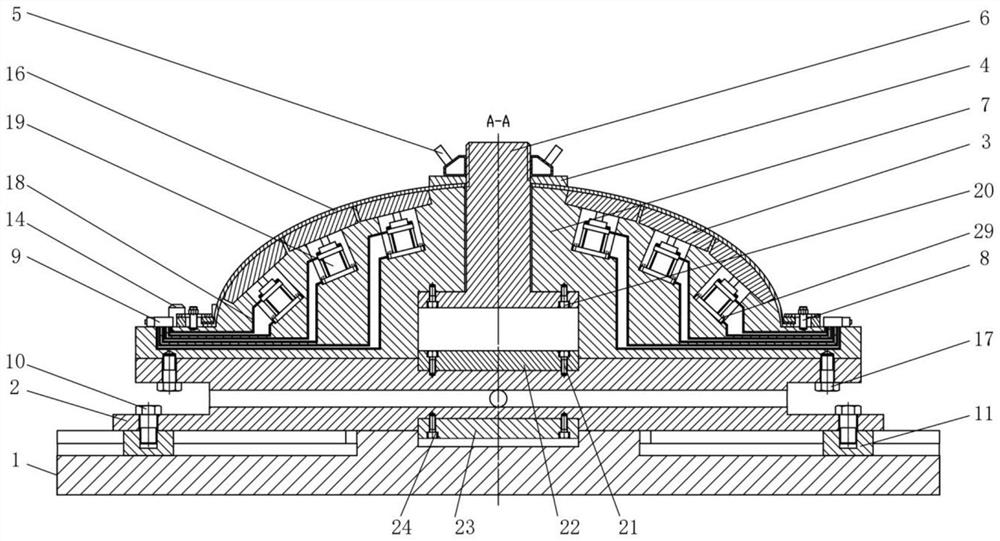

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

[0020] In the embodiment, the spherical crown thin-walled part 16 is integrally formed by stamping and stretching of an aluminum alloy plate, the upper small end has an aperture diameter of 420mm, the lower large end has an outer diameter of 3350mm, and a height of about 900mm. The wall thickness of the workpiece varies from 28mm (small end) to 15mm (big end) along the direction of the generatrix.

[0021] First, assemble the automatic inner support fixture rig, such as figure 1 and figure 2 , consists of positioning clamping device, auxiliary device and hydraulic drive system.

[0022]During installation, the mandrel 6 is installed in the middle part of the inner tire film 7, and is fixedly connected with it by the inner bolt 20 of the mandrel; The hydraulic cylinder 19 is embedded in the inner tire membrane 7, and is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com