Material receiving mechanism in landscaping waste sorting system

A sorting system and landscaping technology, applied in the field of receiving mechanisms, can solve the problems of heavy weight and unsatisfactory sorting effect, and achieve the effects of ingenious structure, wide sorting types, and lower use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

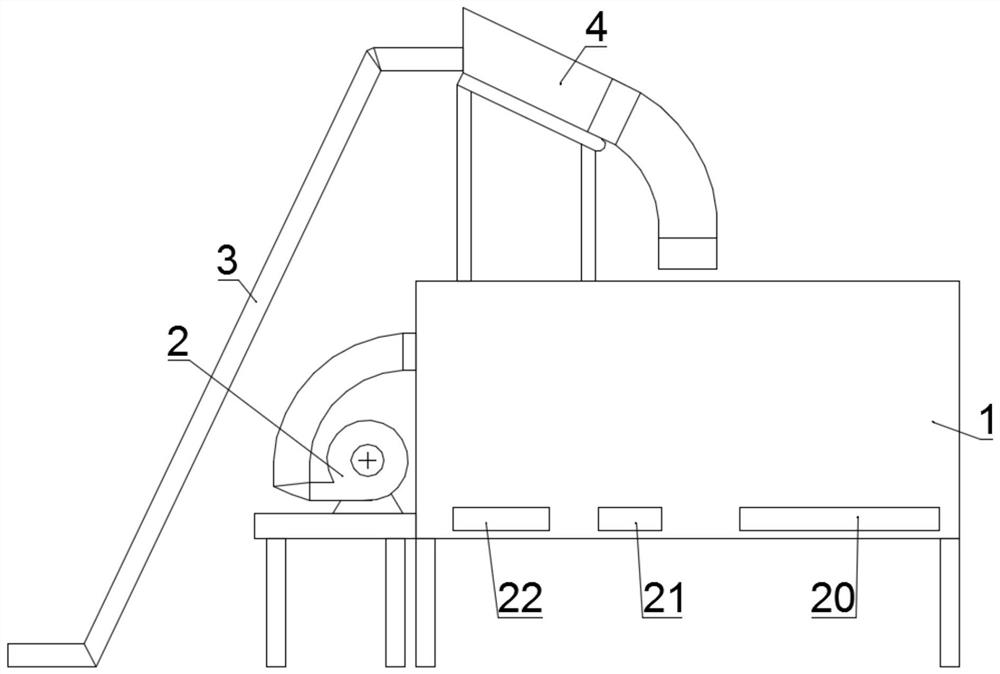

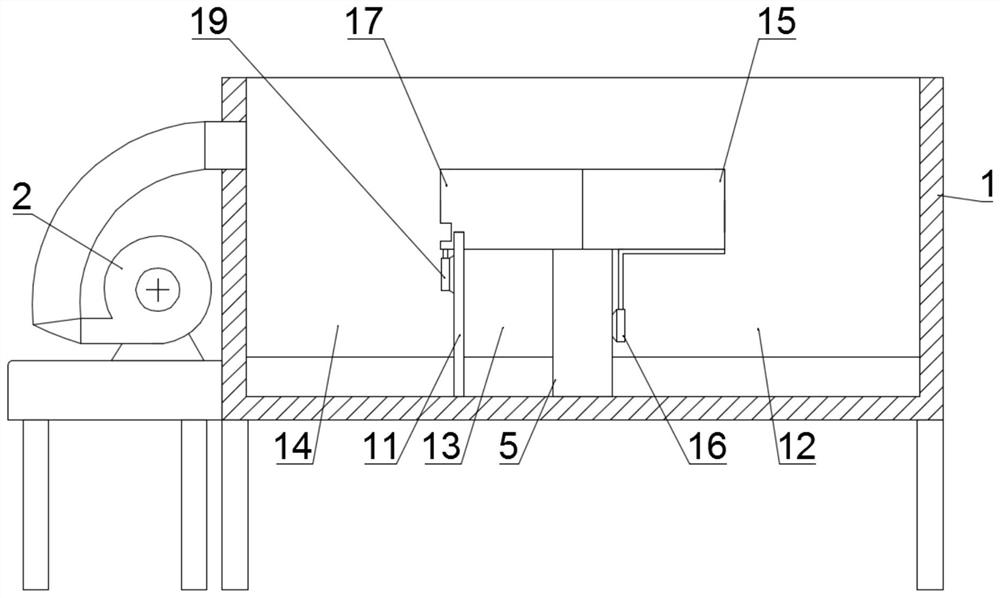

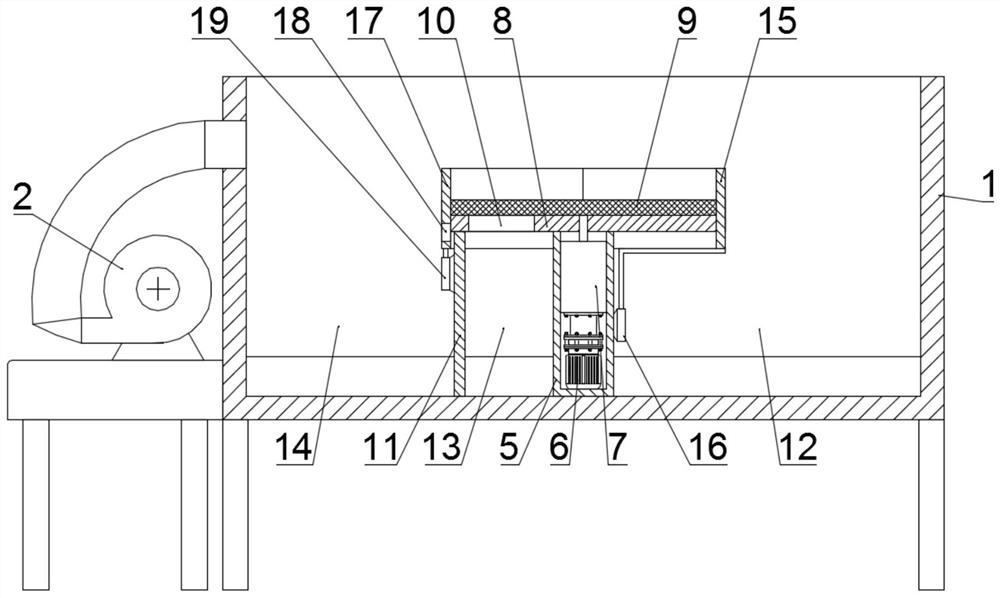

[0036] Such as Figure 1-5 As shown, a material receiving mechanism in a landscaping waste sorting system includes an installation box 5 installed in the sorting box 1, the upper part of the installation box 5 is fixedly connected with a fixed disc 8, and the fixed disc 8 The upper part is provided with the same shape as the fixed disc 8 and coaxially arranged screen 9, such as Figure 3-5 As shown, the fixed disc 8 and the screen cloth 9 are overlapped up and down, and the inside of the installation box 5 is equipped with a rotating drive device, and an output end of the rotating drive device is fixedly connected with the screen cloth 9 coaxially. The fixed disc 8 The lower part of the box is fixedly connected with a partition 11, and the partition 11 and the installation box 5 sequentially divide the inside of the sorting box 1 into a large particle material chamber 14, a small particle material chamber 13 and a recyclable material chamber 12 ,Such as Figure 3-5 As shown,...

Embodiment 2

[0042] On the basis of Example 1, such as Figure 6-9 As shown, the large particle material chamber 14 is provided with a first rotating shaft 23, the first rotating shaft 23 is connected to an output end of the rotating drive device, and at least two fixed rods 24 are fixedly connected to the first rotating shaft 23 along the circumferential direction , the other end of the fixed rod 24 is connected with an arc magnet 25 through a detachable structure, and the inner wall of the large particle material chamber 14 is equipped with a scraper 28, which can be scraped by the scraper 28 when the arc magnet 25 rotates around the first rotating shaft 23 Remove the sundries that are magnetically attracted on the arc magnet 25.

[0043] After the rotation driving device is started, the arc magnet 25 is rotated around the first rotating shaft 23 through the transmission effect of the first rotating shaft 23. Finally, the metal blocks etc. are magnetically attracted on the arc magnet 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com