A kind of building concrete crushing and recycling equipment

A concrete and reuse technology, applied in sustainable waste treatment, grain treatment, solid waste management, etc., can solve the problems of land occupation, environmental pollution, omission of clearance, transportation and stacking, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

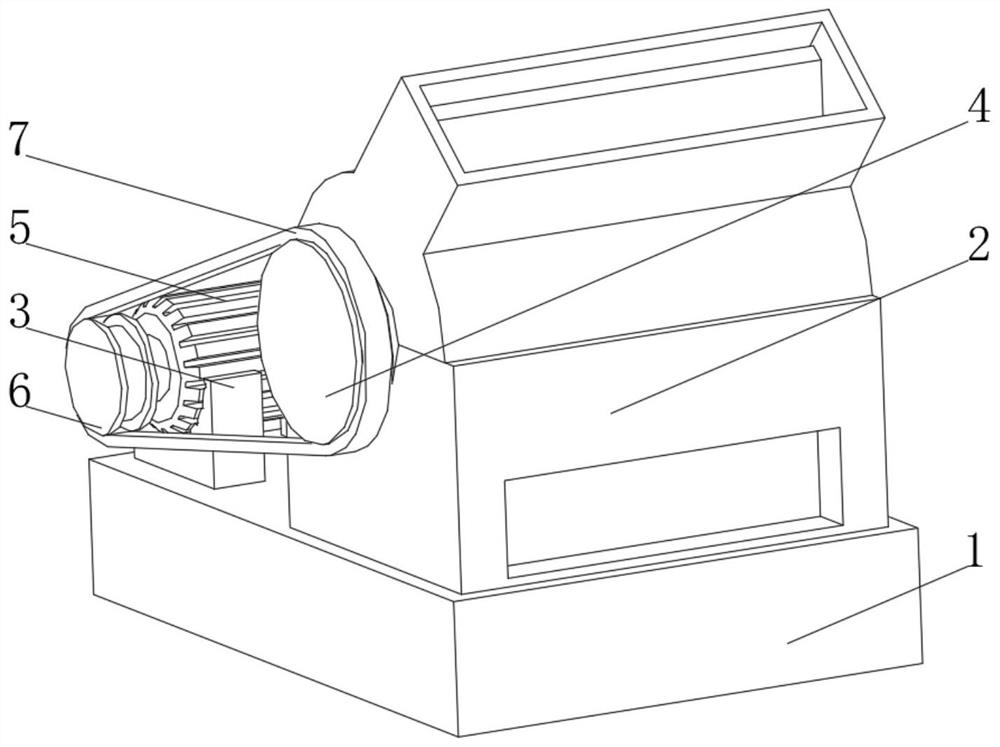

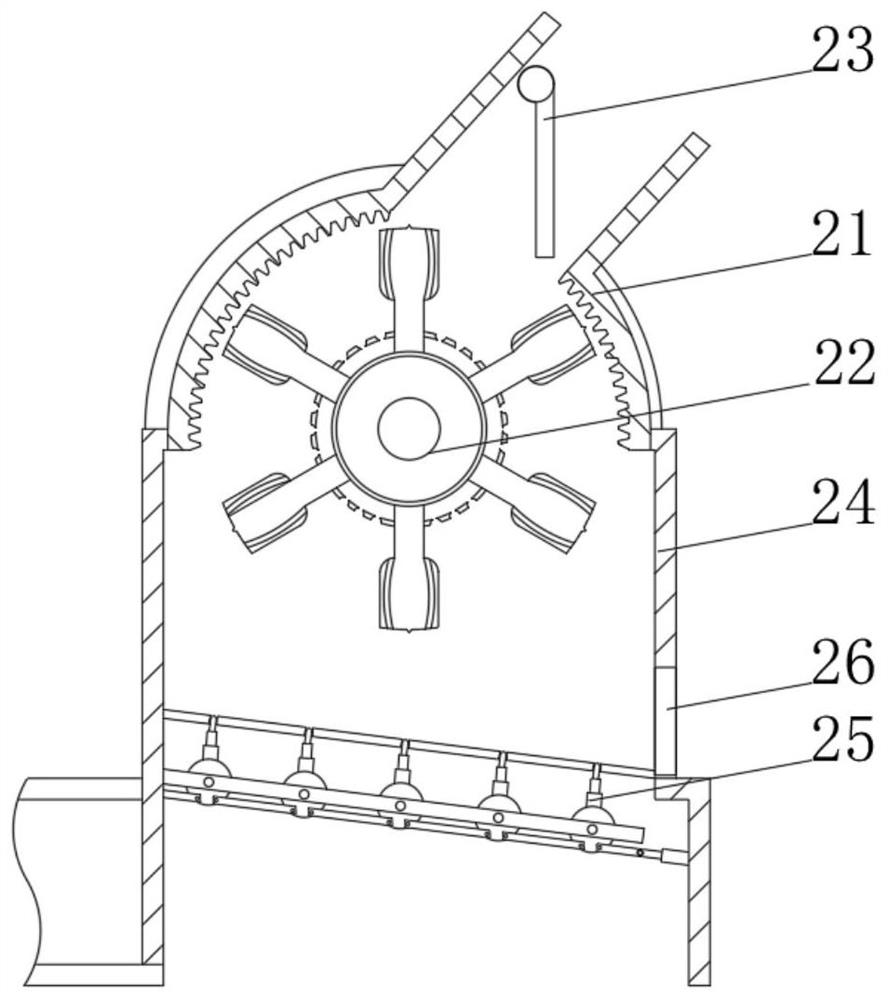

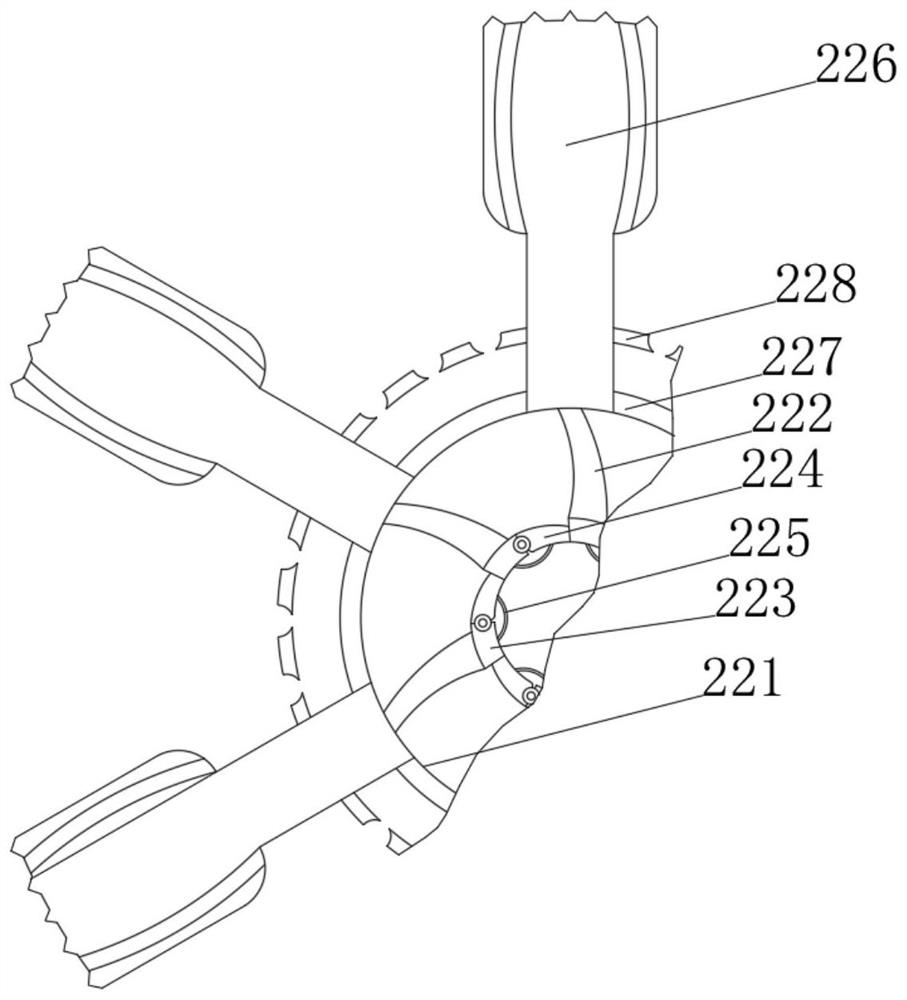

[0035] see Figure 1-3, the present invention provides a technical solution: a building concrete crushing and recycling equipment, including a fixed base 1, the top of the fixed base 1 is respectively provided with a crushing main body 2, a fixed shelf 3, and one side of the crushing main body 2 is provided with a first The power transmission wheel 4, the fixed placement frame 3 is provided with a motor 5 away from the side of the fixed base 1, and one end of the drive shaft of the motor 5 is fixedly connected with a second power transmission wheel 6, and one side of the second power transmission wheel 6 passes through the transmission belt 7 is rotationally connected with the first power transmission wheel 4, the crushing main body 2 includes a feed crushing shell 21, one side of the feed crushing shell 21 is rotatably connected with a crushing mechanism 22, and one end of the feed crushing shell 21 is provided with The curtain 23, the end of the feeding crushing shell 21 awa...

Embodiment 2

[0038] see Figure 2-6 , the present invention provides a technical solution on the basis of Embodiment 1: a kind of construction concrete crushing and reuse equipment, the coarse and fine orthopedic screening mechanism 25 includes a side of the screen plate 251 with a hole cleaning mechanism 252, and the hole cleaning mechanism 252 One end is provided with telescoping device 253, clearing hole mechanism 252 comprises connecting bracket 521, and the inner wall side of connecting bracket 521 is connected with clearing device 522 by rotating shaft rotation, and clearing device 522 is provided with several groups, and clearing device 522 comprises fixed connecting rod a1, the side of the fixed connecting rod a1 is respectively provided with a hole cleaner connecting groove a2 and a rotating connecting groove a3, and the inside of the hole cleaner connecting groove a2 is rotatably connected with a hole cleaner a4 through a rotating pin and a rotating compression spring, and the rot...

Embodiment 3

[0041] see Figure 4-7 , the present invention provides a technical solution on the basis of Embodiment 2: a kind of construction concrete crushing and reuse equipment, the hole cleaner a4 includes a connecting shell a41, the bottom of the inner wall of the connecting shell a41 is provided with a first magnet a42, connected The end of the shell a41 far away from the first magnet a42 is provided with a second magnet a43, and the side of the second magnet a43 far away from the first magnet a42 is fixedly connected with a moving rod a44, and the end of the moving rod a44 far away from the second magnet a43 runs through the connecting housing a41 is also provided with a mounting groove a45, the bottom of the inner wall of the mounting groove a45 is fixedly connected with a compressed airbag a46, and the end of the compressed airbag a46 away from the mounting groove a45 is fixedly connected with a rotating plate a47, and the rotating plate a47 is rotationally connected with the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com