Functional fiber-grade polypropylene production method

A functional fiber and production method technology, applied in the field of polypropylene processing, can solve problems such as product quality problems, difficulty in feeding and mixing uniformly, uneven degradation of polypropylene, etc., and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

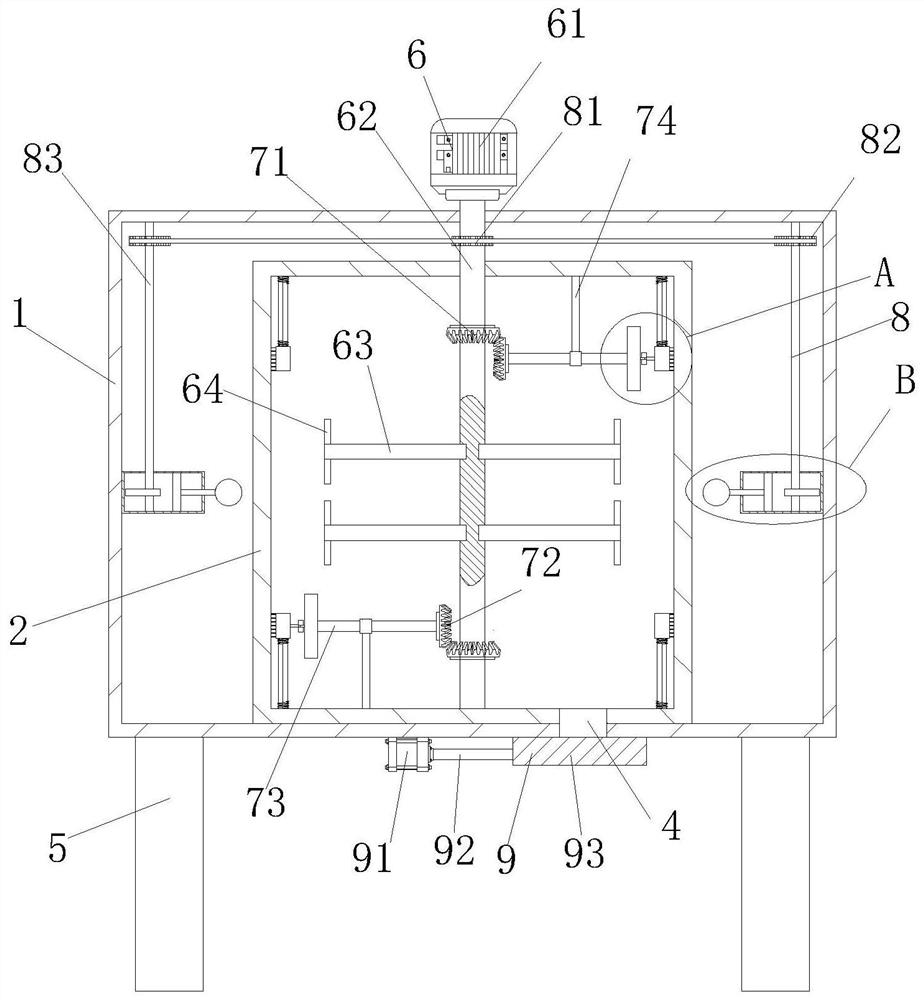

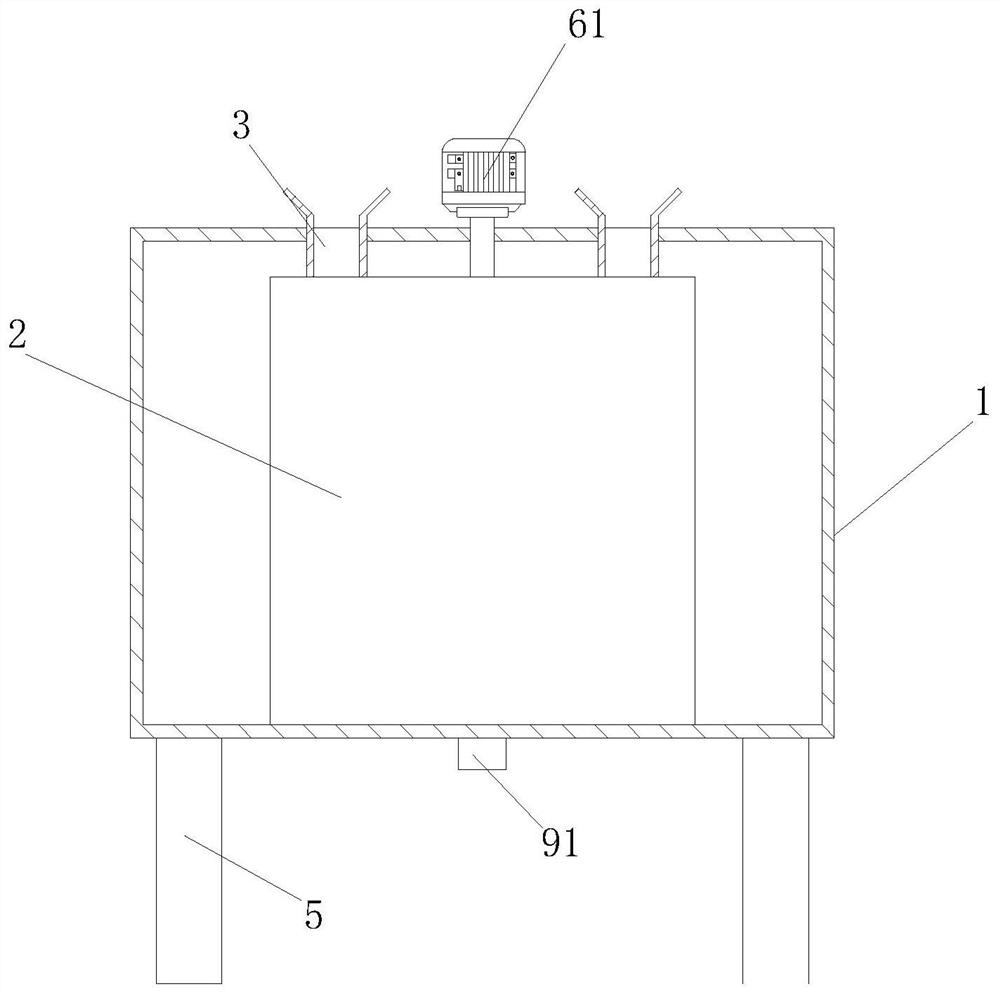

[0039] As an embodiment of the present invention, the transmission assembly 75 includes a disk 751; the disk 751 is fixed on the end of the second rotating shaft 73 away from the second bevel gear 72; the disk 751 is close to the edge There is a revolving pin 752 connected to it in rotation; the side wall of the annular brush plate 76 away from the brush 77 is fixedly connected with a moving plate 753 through a connecting column 755; a chute 754 is provided on the moving plate 753; the revolving pin 752 Slidingly connected in the chute 754; during work, when the disc 751 rotates, the movement of the rotating pin 752 in the chute 754 drives the moving plate 753 to move, and the moving plate 753 moves through the connecting column 755 to drive the annular brush plate 76 to move up and down. To clean the powder bonded in the mixing tank 2.

[0040] As an embodiment of the present invention, a group of vibrating mechanisms 8 are provided on the inner wall of the housing 1; the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com