A kind of ultra-low pressure membrane separation system and separation method

A separation system and separation method technology, applied in ultra-low pressure membrane separation system and separation field, can solve the problems of increased final benefit, increased adsorption effect and non-specific interception, reduced macroscopic filtration efficiency of membrane fluid, etc., to achieve improved separation efficiency , The effect of shortening the separation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Such as Figure 11 As shown, an ultra-low pressure membrane separation system includes an ultra-low pressure generating device, a membrane scaling control module, a flow rate control device, and a pressure detection device; the ultra-low pressure generating device is configured to provide The required ultra-low pressure, the ultra-low pressure is between 0.01KPa and 40KPa; the membrane scale control module is configured to keep the membrane scale layer in a single layer or loose state; the flow rate control device is configured to The flow rate of the sample to be filtered can be controlled, and the pressure detection device is configured to detect the pressure.

[0044] In some preferred modes, the ultra-low pressure generating device includes a filter membrane with low transmembrane resistance, a filter membrane packaging device, and a guide tube; the filter membrane is located between the package devices, and the guide tube 15 is connected to the package device. The...

Embodiment 2

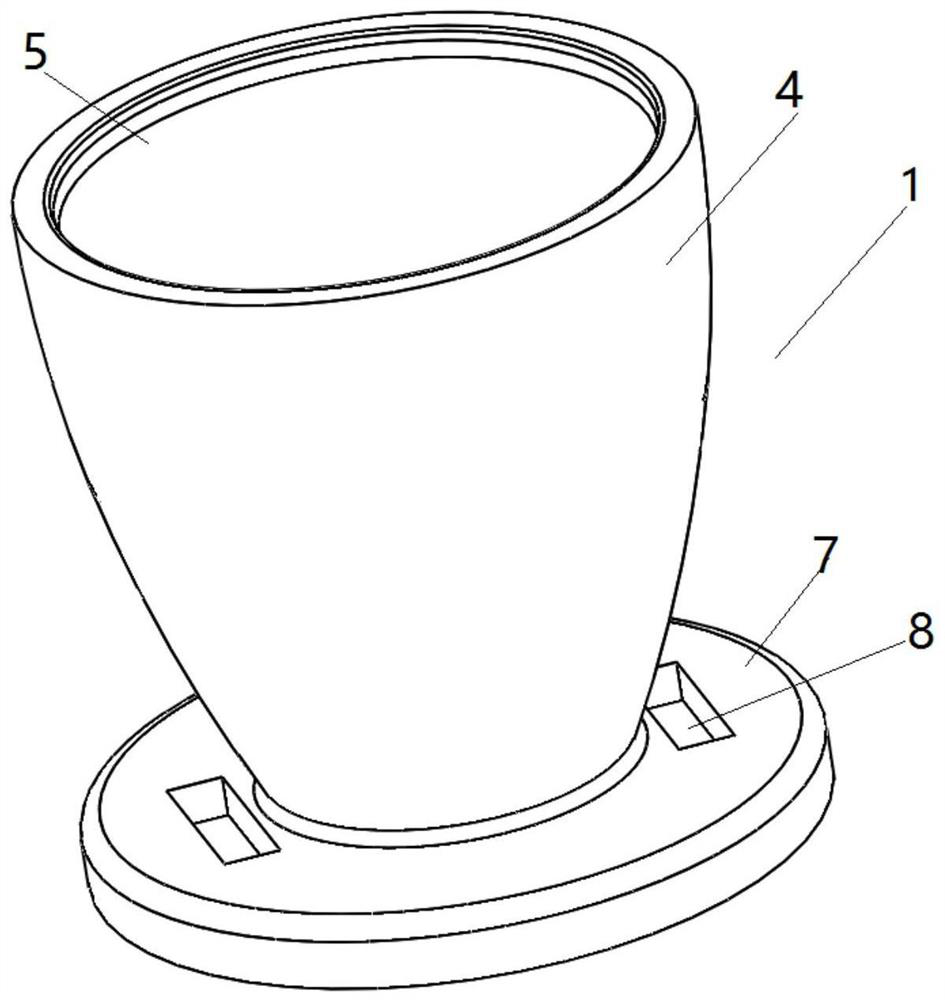

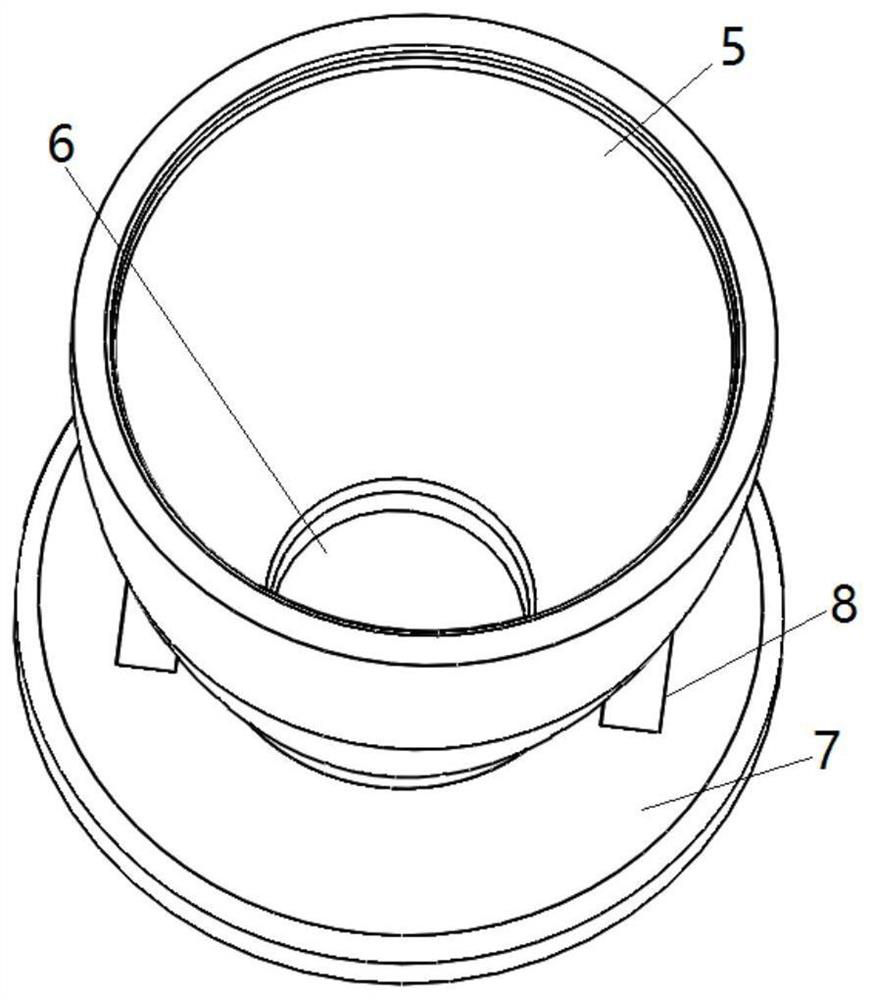

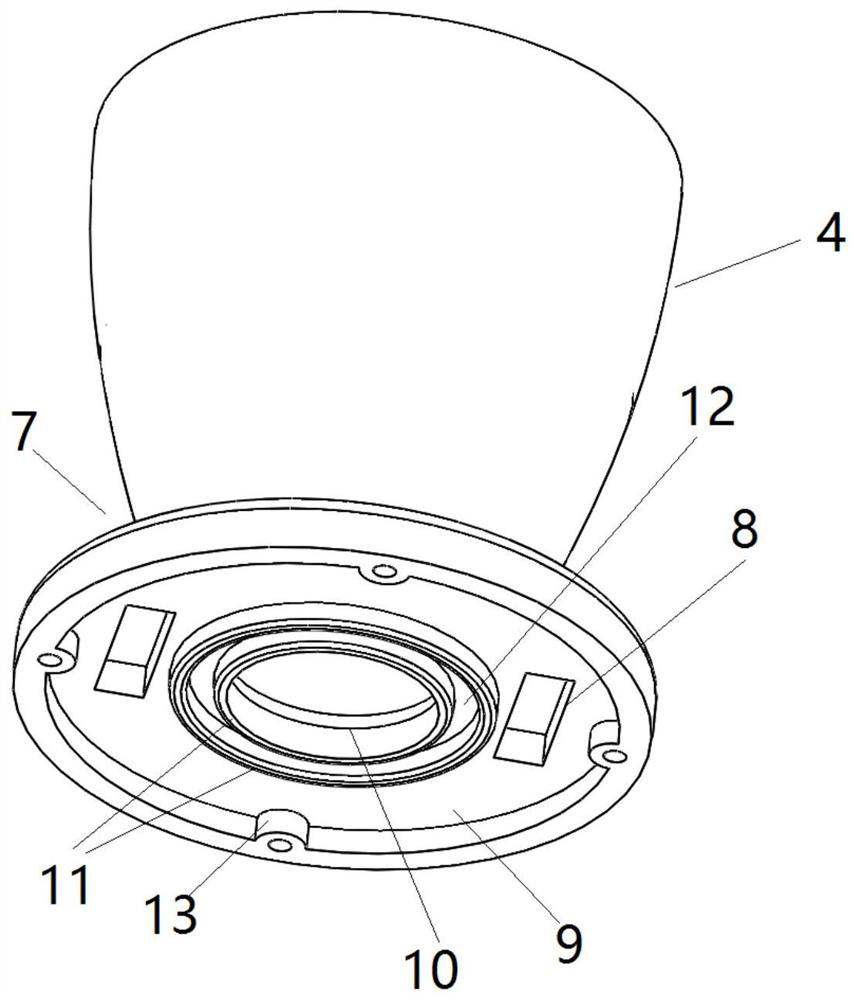

[0100] Embodiment 2, with reference to attached Figure 1-5 .

[0101] Specifically, in this embodiment, as Figure 1-5 As shown, the packaging device includes a first fixing part 1, a second fixing part 2 and a sealing part 3, and the first fixing part 1 and the second fixing part 2 are configured to be able to cooperate for fixing and packaging the filter membrane; the sealing The element 3 is an elastic sealing element 3, and the elastic sealing element 3 is located between the first fixing element and the second fixing element, and the elastic sealing element 3 is configured to be able to seal the device, so as to prevent the sample to be filtered from flowing out laterally during filtering, and, The elastic seal has elasticity and can be deformed. When the elastic seal contacts with the filter membrane, it will not stab or damage the filter membrane, which is beneficial to ensure the smoothness of the filter membrane surface. In some preferred manners, the sealing membe...

Embodiment 3

[0128] Embodiment 3 is with reference to attached Figure 6 ,8.

[0129] In this example, if Figure 6 As shown, the first fixing member includes a first cavity 4 and a base, and the shape of the first cavity is similar to that of a cone. In other embodiments, the shape of the first cavity 4 may be cuboid, cube, cylinder or other shapes, and the present invention does not limit the specific shape of the first cavity. The size and shape of the first cavity will not affect the negative pressure under the membrane, but the height of the liquid to be filtered on the filter membrane should not be too high, otherwise a non-negligible positive pressure will be generated.

[0130] In some preferred manners, the upper section of the first cavity 4 is provided with a mounting portion for mounting a corresponding cover. The installation part may be an outwardly protruding rib or an inwardly recessed groove or a screw thread or a snap-fit structure, or any other suitable structure fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com