Method for producing wavelength conversion sheet, phosphor protective film, wavelength conversion sheet with release film, and wavelength conversion sheet

A manufacturing method and wavelength conversion technology, applied in chemical instruments and methods, optics, optical filters, etc., can solve problems such as performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

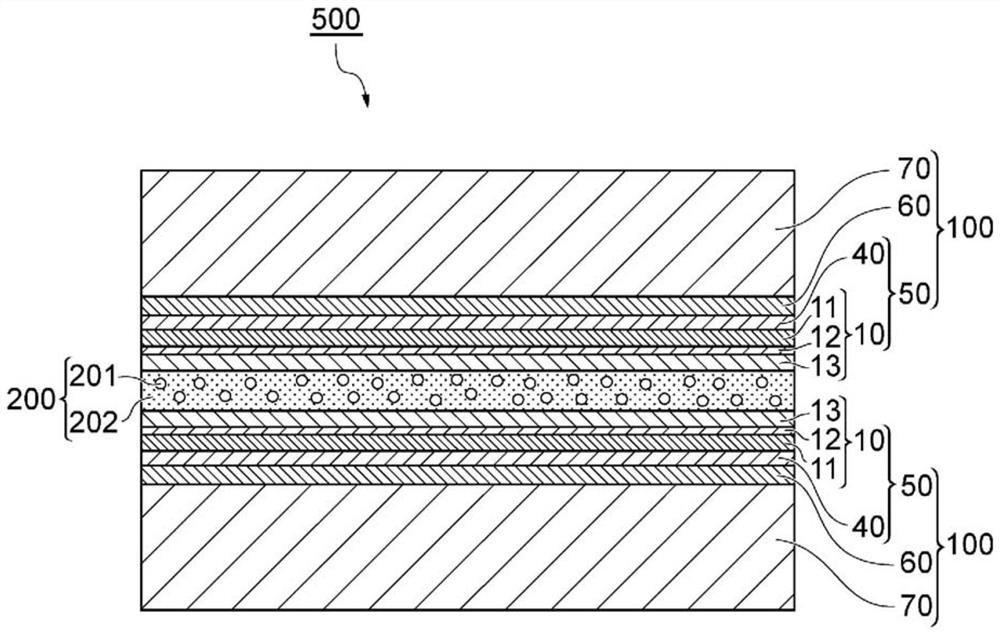

[0133] Barrier films were fabricated as described below. First, silicon oxide was provided as an inorganic thin film layer by a vacuum evaporation method on one side of a PET film as a barrier film base material, and a gas barrier coating layer was further formed on the inorganic thin film layer. This gas-barrier coating layer is formed by applying a coating solution obtained by mixing tetraethoxysilane and polyvinyl alcohol at a mass ratio of 1:1 by a wet coating method, and then heating and drying at 180°C for 1 minute. of. Thus, a barrier film in which the inorganic thin film layer and the gas barrier coating layer were provided on one surface of the substrate was obtained. It should be noted that the thickness of the barrier film was 12.5 μm, the thickness of the barrier film substrate was 12 μm, the thickness of the inorganic thin film layer was 30 nm, and the thickness of the gas barrier coating layer was 0.5 μm.

Embodiment 2 to 6

[0138] Phosphor protective films of Examples 2 to 6 were obtained in the same manner as in Example 1 except that the thickness of the barrier film and the thickness of the peeling film were changed to the thicknesses shown in Table 1, respectively. Here, when the thickness of the barrier film was set at 23.5 μm, the thicknesses of the inorganic thin film layer and the gas barrier coating layer did not change, and the thickness of the barrier film substrate was set at 23 μm.

Embodiment 7

[0140] Barrier films were fabricated as described below. First, silicon oxide was provided as an inorganic thin film layer by a vacuum evaporation method on one side of a PET film as a barrier film base material, and then a gas barrier coating layer was formed on the inorganic thin film layer. This gas barrier coating layer is formed by applying a coating solution obtained by mixing tetraethoxysilane and polyvinyl alcohol at a mass ratio of 1:1 by a wet coating method, followed by heating and drying at 180°C for 1 minute. . Thus, a barrier film in which the inorganic thin film layer and the gas barrier coating layer were provided on one surface of the substrate was obtained. It should be noted that the thickness of the barrier film was 12.5 μm.

[0141] Next, 100 parts by mass of an acrylic adhesive (manufactured by Cyden Chemical Co., Ltd., trade name: Cybinol OC-3405), 1 part by mass of an isocyanate curing agent ( Cyden Chemical Co., Ltd., trade name: Cybinol K-341), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com