A hybrid integrated circuit fixed structure for rotary vacuum vapor phase cleaning

A hybrid integrated circuit and fixed structure technology, applied in secondary processing of printed circuits, assembling printed circuits with electrical components, cleaning/polishing of conductive patterns, etc., to achieve the effect of improving fixability, ensuring stability, and avoiding circuit fixation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

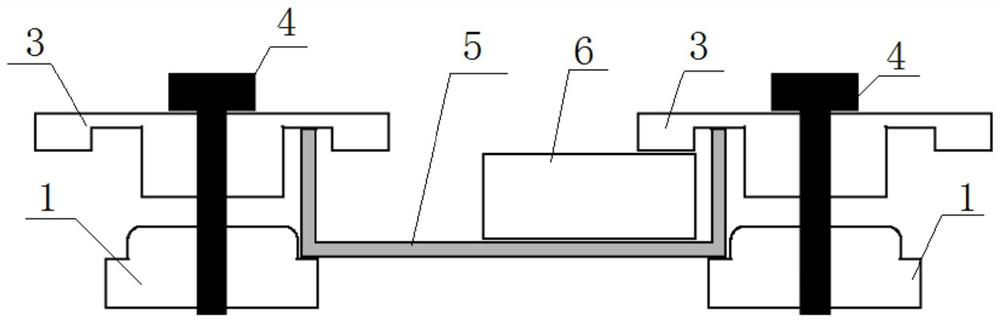

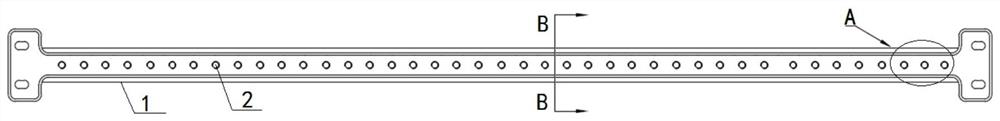

[0033] The invention provides a hybrid integrated circuit fixing structure for rotary vacuum vapor phase cleaning, such as figure 1 and figure 2 As shown, it includes a circuit case 5, a frame body 7, and several beams 1 and pressing blocks 3; the two ends of several beams 1 are respectively fixed on the frame body 7, and the circuit case 5 is in the shape of a hybrid integrated circuit. It is fixed inside the circuit case 5, and the two sides of the bottom of the circuit case 5 are placed on the beam wall of the adjacent beam 1. The inside of the circuit case 5 is exposed to the outside, and several pressing blocks 3 are fixedly connected to the beam 1. And the two sides of the briquetting block 3 are respectively pressed on the two sides of the top of the circuit case 5 to realize the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com