Lithium ion battery composite membrane, preparation method thereof and lithium ion battery

A lithium-ion battery and composite diaphragm technology, which is applied in secondary batteries, battery pack components, secondary battery repair/maintenance, etc., can solve the problem of decreased energy density of battery systems, difficulty in ensuring uniform thickness, and cumbersome coating process and other problems, to achieve excellent thermal stability, avoid further expansion of thermal runaway, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

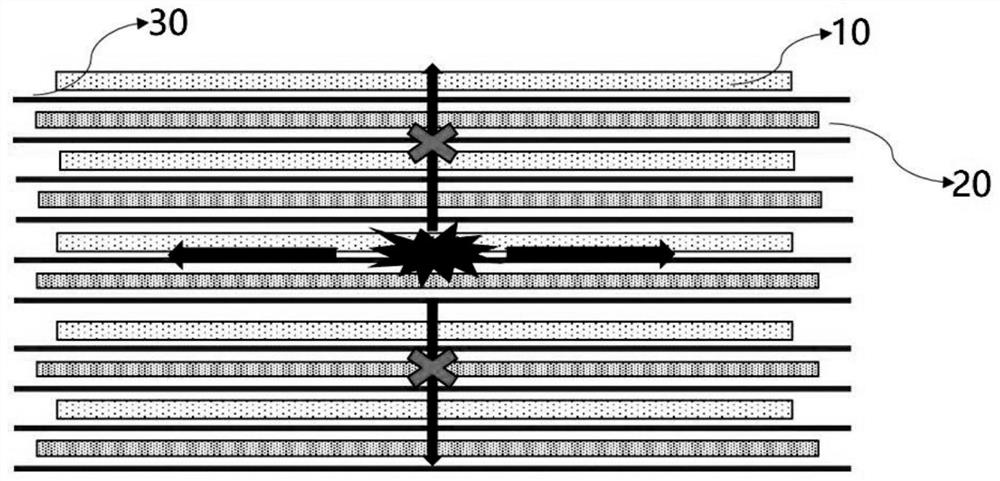

[0034] A second aspect of the present invention provides a method for preparing a lithium-ion battery composite diaphragm as described in any one of the first aspect of the present invention, comprising the following steps:

[0035] Dissolving the exfoliated Boron Nitride nanosheets in an organic solvent to obtain a first solution;

[0036] Dissolving P(VDF-HFP) powder in an organic solvent to obtain a second solution;

[0037] After the first solution and the second solution are uniformly mixed, they are coated on the surface of the base film and dried to obtain a lithium-ion battery composite separator.

[0038] The preparation method adopts the method of oil-based mixed coating, and the process is simple, does not require multiple coatings, and is easy to realize industrialization.

[0039] Further, the selection of the organic solvent in the first solution and the second solution in the present invention is not particularly limited, as long as it meets the purpose of diss...

Embodiment 1

[0047] Add 0.6kg of stripped Boron Nitride nanosheets (thickness 1-10nm, size 100-500nm) into 200kg NMP to dissolve, fully stir and dissolve to obtain the first solution;

[0048] Add 20kg of P(VDF-HFP) powder into 200kg of NMP to dissolve, fully stir and dissolve to obtain the second solution;

[0049] After mixing the first solution and the second solution, fully stir them evenly, and apply them on the surface of the PE base film with a micro-gravure roller to prepare a lithium-ion battery composite separator. The thickness of the coating layer is 1 μm, and the surface density is 0.5g / m 2 .

Embodiment 2

[0051] Add 0.6kg of stripped Boron Nitride nanosheets (thickness 1-10nm, size 100-500nm) into 200kg acetone to dissolve, fully stir and dissolve to obtain the first solution;

[0052] Add 60kg of P(VDF-HFP) powder into 200kg of acetone to dissolve, fully stir and dissolve to obtain the second solution;

[0053] After mixing the first solution and the second solution, stir well and apply it on the surface of the PP separator with a micro-concave roller to prepare a lithium-ion battery composite separator. The thickness of the coating layer is 5 μm, and the surface density is 3.5 g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com