High-strength drawing magnetic slot wedge and manufacturing method

A technology for magnetic slot wedges and manufacturing methods, which is applied in the direction of inductance/transformer/magnet manufacturing, magnetic materials, magnetic objects, etc., and can solve the problems of mixing state of iron powder and glue, when adding iron powder, and iron powder. The powder is easy to loose and fall off, so as to avoid cutting defects, stabilize magnetic properties, and increase mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

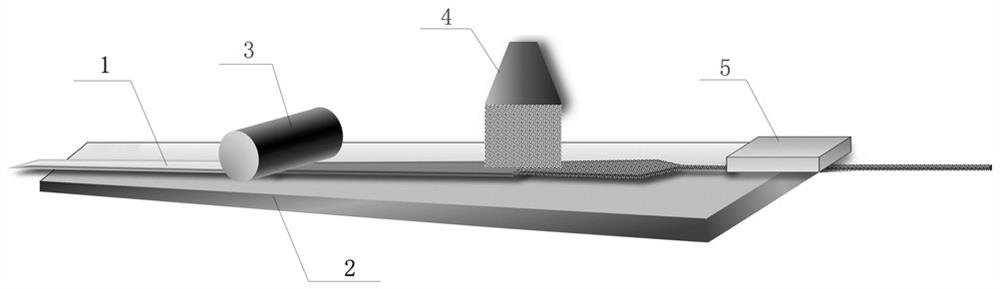

[0023] A method for manufacturing a high-strength pull-out magnetic slot wedge, comprising the following steps: figure 1 as shown,

[0024] (1) Preparation of adhesive: Mix base resin and curing agent to make adhesive, take 20 parts of epoxy resin and 10 parts of anhydride curing agent to make adhesive.

[0025] (2) Glass fiber cloth gluing: flatten and straighten a layer of glass fiber cloth 1 so that it can pass through the conveying device 2 smoothly, and add bundles of 15mm alkali-free glass fibers on it, and pass through the gluing machine 3 to give Glass fiber cloth 1. E-glass fiber gluing. The thickness of the glass fiber cloth used is 0.15 mm, and the hole diameter is <1 mm.

[0026] (3) Powdering: Sprinkle 200-mesh iron powder evenly on the glass fiber cloth 1 to make it adhere to the glass fiber cloth; use the powder meter 4 to control the powder falling speed, so that the powder falling The mass of iron powder is about 4 times the mass of the adhesive on the glas...

Embodiment 2

[0029] Steps (2)-(4) in Example 2 are the same as in Example 1, the only difference is that the curing agent in step (1) is replaced by 20 parts of amine curing agent.

Embodiment 3

[0031] Steps (2)-(4) in Example 3 are the same as in Example 1, the only difference is that in step (1), the base resin is replaced with unsaturated polyester resin, and the curing agent is replaced with 0.2 parts of peroxide curing agent .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com