Bridge drainage system and drainage method thereof

A drainage system and bridge technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of simple pipelines and easy blockage of drainage pipes, and achieve the effect of avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

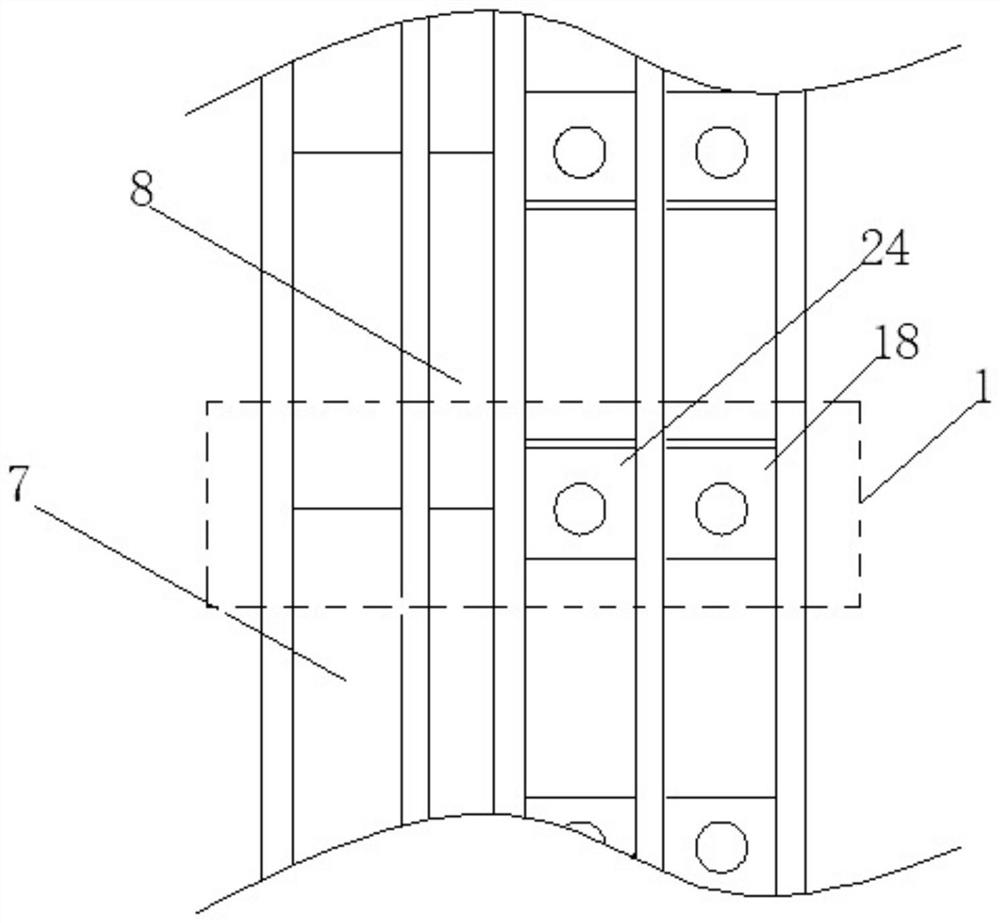

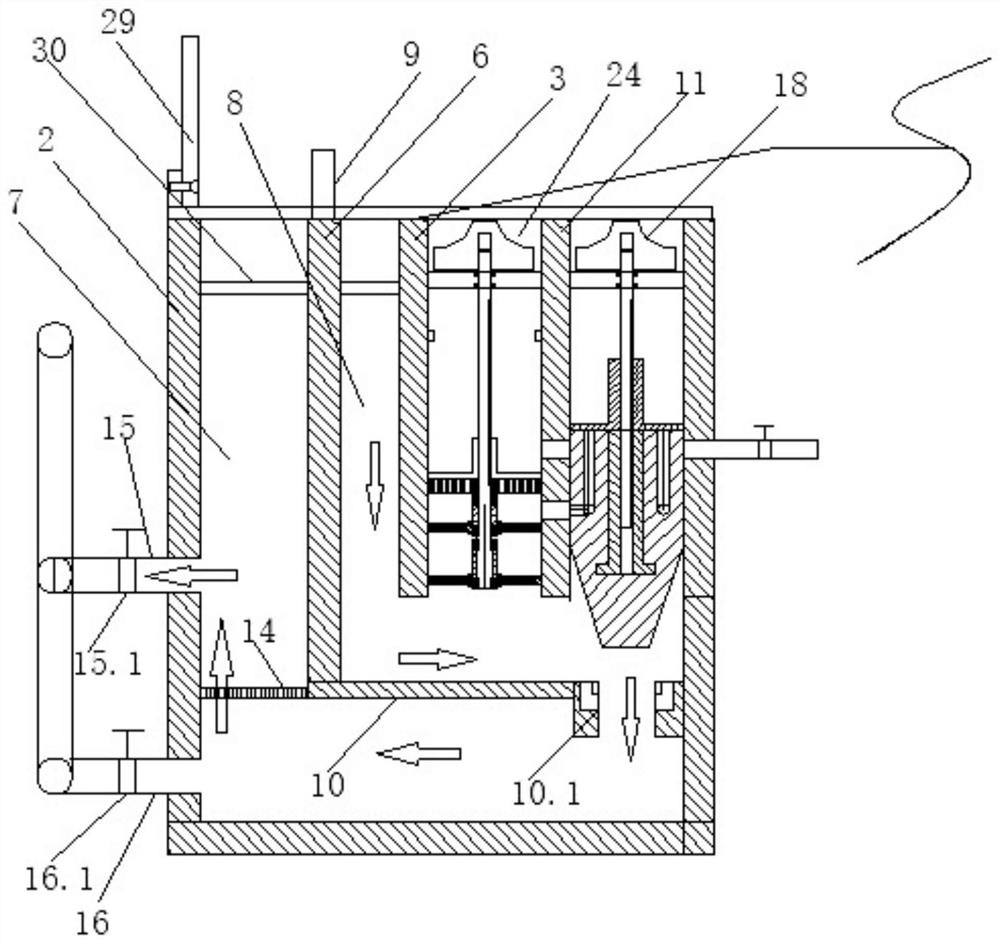

[0044] In the bridge drainage system, several drainage units 1 are respectively arranged on both sides of the bridge, and a drainage unit 1 is arranged at intervals on the same side of the bridge; 3 is divided into a first cavity 4 and a second cavity 5, the first cavity 4 is divided into a first drainage ditch 7 and a second drainage ditch 8 by a drainage side longitudinal partition plate 6, and the drainage side longitudinal partition plate 6. A longitudinal overflow plate 9 is installed on the upper part. The longitudinal overflow plate 9 at this position can control the rainwater to be discharged to the second drainage ditch 8 when the rainfall is small, and start the drainage mode of the small rainfall drainage stage. If necessary, a water pump can be set at a suitable position in the passage. The first drainage ditches 7 of all the drainage units on the same side of the bridge communicate with each other, and the second drainage ditches 8 of all the drainage units on the...

Embodiment 2

[0062] In the bridge drainage system, several drainage units 1 are respectively arranged on both sides of the bridge, and a drainage unit 1 is arranged at intervals on the same side of the bridge; 3 is divided into a first cavity 4 and a second cavity 5, the first cavity 4 is divided into a first drainage ditch 7 and a second drainage ditch 8 by a drainage side longitudinal partition plate 6, and the drainage side longitudinal partition plate 6. A longitudinal overflow plate 9 is installed on the upper part. The first drainage ditches 7 of all drainage units on the same side of the bridge are connected to each other, and the second drainage ditches 8 of all drainage units on the same side of the bridge are connected to each other.

[0063] The bottom of the longitudinal partition plate 6 on the drainage side is fixed with a transverse partition plate 10, and the transverse partition plate 10 extends from the longitudinal partition plate 6 on the drainage side to the side wall o...

Embodiment 3

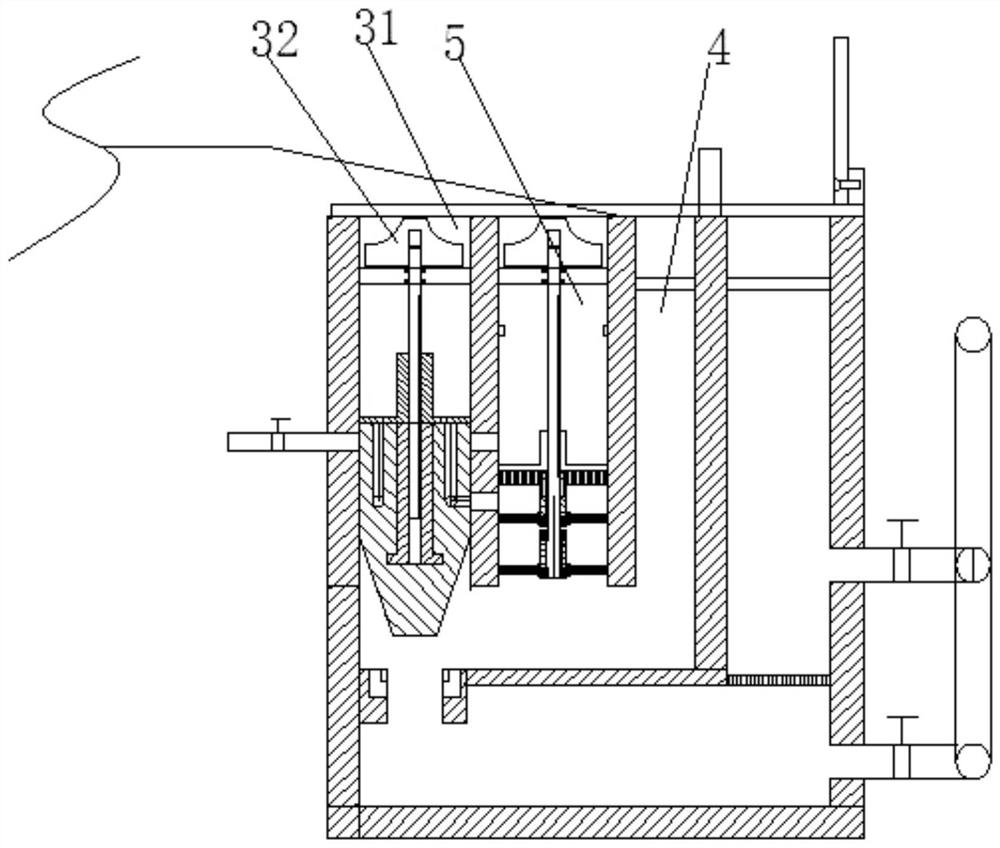

[0080] In the bridge drainage system, several drainage units 1 are respectively arranged on both sides of the bridge, and a drainage unit 1 is arranged at intervals on the same side of the bridge; 3 is divided into a first cavity 4 and a second cavity 5, the first cavity 4 is divided into a first drainage ditch 7 and a second drainage ditch 8 by a drainage side longitudinal partition plate 6, and the drainage side longitudinal partition plate 6. A longitudinal overflow plate 9 is installed on the upper part. The first drainage ditches 7 of all drainage units on the same side of the bridge are connected to each other, and the second drainage ditches 8 of all drainage units on the same side of the bridge are connected to each other.

[0081] The bottom of the longitudinal partition plate 6 on the drainage side is fixed with a transverse partition plate 10, and the transverse partition plate 10 extends from the longitudinal partition plate 6 on the drainage side to the side wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com