Heating circulating pump and washing machine

A heating cycle and heating element technology, which can be applied to other washing machines, washing devices, textiles and paper making, etc., can solve the problems of lint and heating elements in contact and entangle, and achieve the effect of suitable promotion and use, improving heating efficiency and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

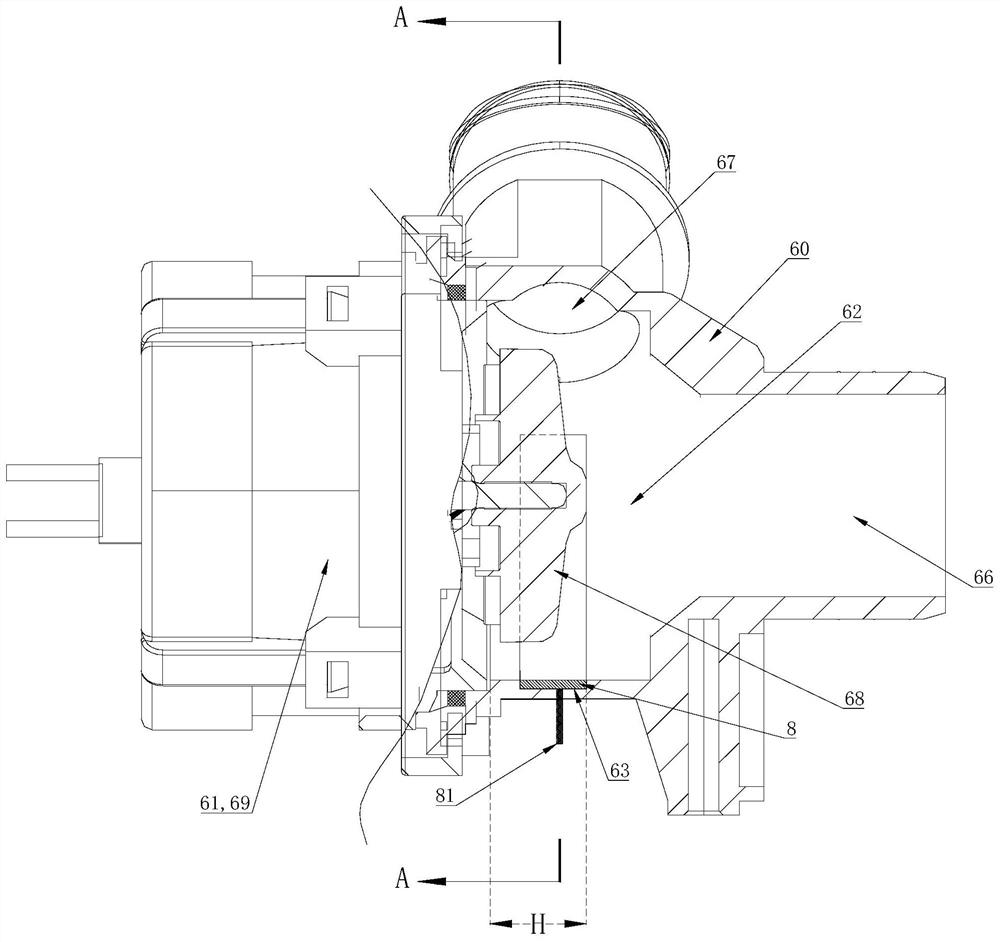

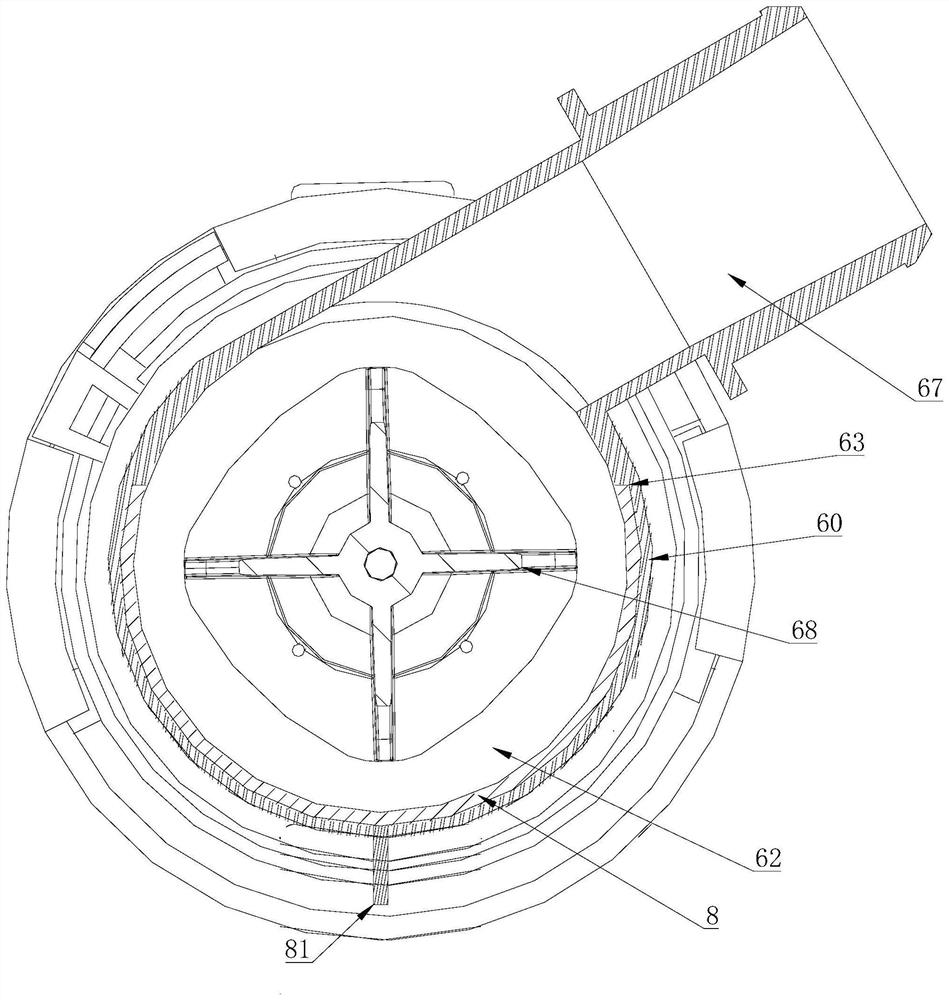

[0041] Such as Figures 2 to 3 As shown, a heating circulation pump 6 is introduced in this embodiment, which includes a pump casing 60, which is provided with a pump chamber 62 for water to flow through; the inner wall of the pump casing 60 is provided with a groove 63, the groove 63 is provided with a heating element 8, and the heating element 8 is in contact with the water flowing through the pump chamber 62 to heat the water flowing through it. The heating element 8 and the inner wall of the pump casing 60 together form a pump chamber 62, and the junction between the heating element 8 and the inner wall of the pump casing 60 forms a smooth surface, so as to prevent foreign matter such as wire scraps trapped in the water flowing through the pump chamber from being entangled by the heating element Intercept and avoid the occurrence of foreign matters such as lint dust being trapped in the pump cavity.

[0042]In this embodiment, all the heating elements 8 are located in the...

Embodiment 2

[0049] Such as figure 2 with image 3 As shown, a heating circulation pump 6 is introduced in this embodiment, which includes a pump casing 60, and a pump chamber 62 is provided inside the pump casing 60 for the water to flow through; The water inlet 66 is provided with a driving device 61 at the other end, so that the heating element 8 heats the water flowing into the pump chamber 62 from the water inlet 66 , and then the heated water flows out from the water outlet 67 through the driving device 61 . At the same time, the water inlet 66 is arranged on one end of the columnar pump casing 60, and the water outlet 67 is arranged on the side wall of the pump casing 60 near the end of the driving device 61, so that the axes of the water inlet 66 and the water outlet 67 are vertically arranged to facilitate the water inlet. The water outlet 66 and the water outlet 67 are respectively connected with pipelines.

[0050] In this embodiment, the driving device 61 includes an impelle...

Embodiment 3

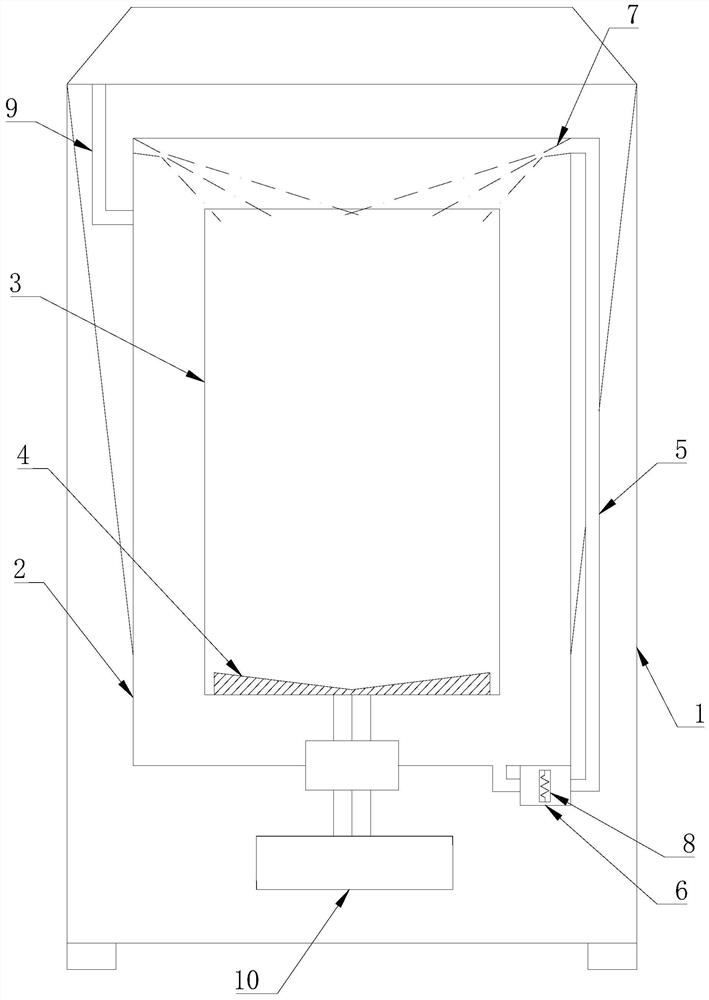

[0060] Such as Figure 1-3 As shown, this embodiment introduces a washing machine equipped with the circulating heating pump 6 described in the above embodiments, which includes a housing 1; an outer tub 2 is arranged inside the housing 1, and the outer tub 2 can generate heat through a shock absorbing device. The vibration displacement is installed on the shell 1 to hold the washing water; the inner barrel 3 is provided in the outer barrel 2, and the inner barrel 3 is connected with the drive motor 10 through the rotating shaft, and is installed in the outer barrel 2 in a rotatable manner for Hold the load to be washed; the inner barrel 3 is provided with a washing hole, which is used to connect the inner barrel 3 and the outer barrel 2, so that the washing water can flow between the inner and outer barrels through the washing hole; the water inlet pipe 9, the water outlet and the The outer tub 2 is connected to each other and is used to supply water to the outer tub 2 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com