Electric response shape memory composite material and preparation method thereof

A composite material and electrical response technology, applied in the field of electrical response shape memory composite materials and their preparation, can solve the problems of destroying the mechanical properties of composite materials, limiting the application of SMP, and the influence of shape memory effect, etc., achieving simple preparation method and improving shape memory. Response rate, repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing an electrically responsive shape memory composite material, comprising the steps of:

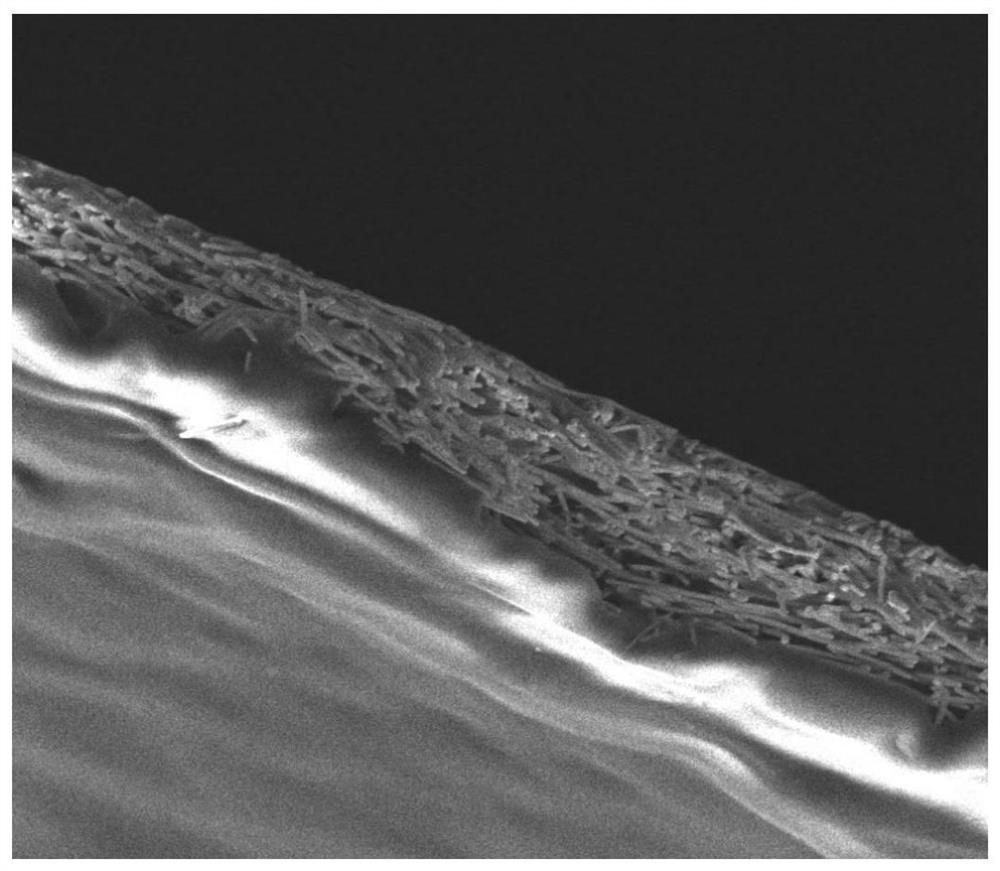

[0033] (1) Take 100 ul of silver nanowire dispersion with a concentration of 0.5 mg / ml and apply it to the surface of the substrate, after drying, put it into an oven at 100° C. for annealing for 10 minutes to form a silver nanowire conductive film;

[0034] (2) Weigh 2 g of poly-L-lactic acid, poly-d-lactic acid and polycaprolactone particles with a mass ratio of 35:35:30 in a beaker, take 50 ml of chloroform as a solvent to dissolve PLLA, PDLA, and PCL particles, Stir at room temperature until uniform;

[0035] (3) Place the substrate with the silver nanowire conductive film in a flat dish, take 20ml of poly-L-lactic acid, poly-D-lactic acid and polycaprolactone blend solution and apply it evenly to the surface of the silver nanowire, and dry it at room temperature After the film is formed, it is placed in an oven at 160° C. for annealing for 10 minutes. Afte...

Embodiment 2

[0038] A method for preparing an electrically responsive shape memory composite material, comprising the steps of:

[0039] (1) Take 100 ul of silver nanowire dispersion with a concentration of 1 mg / ml and apply it to the surface of the substrate. After drying, put it in an oven at 100° C. for annealing for 10 minutes to form a silver nanowire conductive film;

[0040] (2) Weigh 2 g of poly-L-lactic acid, poly-d-lactic acid and polycaprolactone particles with a mass ratio of 35:35:30 in a beaker, take 50 ml of chloroform as a solvent to dissolve PLLA, PDLA, and PCL particles, Stir at room temperature until uniform;

[0041] (3) Place the substrate with silver nanowire conductive film in a flat dish, take 20ml poly-L-lactic acid, poly-D-lactic acid and polycaprolactone blend solution and apply it evenly to the surface of silver nanowire, dry at room temperature After the film is formed, it is placed in an oven at 160° C. for annealing for 10 minutes. After annealing, it is coo...

Embodiment 3

[0044] A method for preparing an electrically responsive shape memory composite material, comprising the steps of:

[0045] (1) Take 100 ul of silver nanowire dispersion with a concentration of 1.5 mg / ml and apply it to the surface of the substrate. After drying, put it in a 100° C. oven and anneal for 10 minutes to form a silver nanowire conductive film;

[0046] (2) Weigh 2 g of poly-L-lactic acid, poly-d-lactic acid and polycaprolactone particles with a mass ratio of 35:35:30 in a beaker, take 50 ml of chloroform as a solvent to dissolve PLLA, PDLA, and PCL particles, Stir at room temperature until uniform;

[0047] (3) Place the substrate with the silver nanowire conductive film in a flat dish, take 20ml of poly-L-lactic acid, poly-D-lactic acid and polycaprolactone blend solution and apply it evenly to the surface of the silver nanowire, and dry it at room temperature After the film is formed, put it into an oven with a temperature of 160°C for annealing, the annealing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com