Hydroxy acrylic resin suitable for heat reflective thermal insulation coating and preparation method thereof

A technology of hydroxy acrylic acid and thermal insulation coating, applied in the direction of reflection/signal coating, coating, etc., can solve the problems of harsh construction requirements of water-based paint, easy to appear ill-conditioned coating film, not necessarily adaptable and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

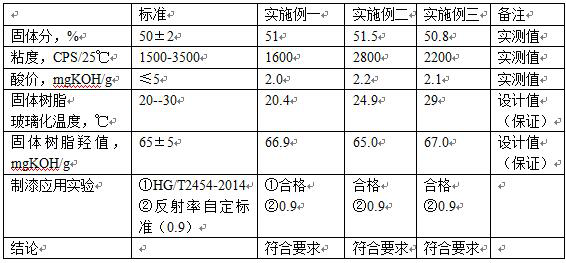

Examples

Embodiment 1

[0027] The hydroxy acrylic resin suitable for the heat-reflecting and heat-insulating paint of this embodiment includes the following raw materials in parts by weight:

[0028] Bottom material: 37 parts of butyl acetate;

[0029] Mixed monomer dropwise addition: 10 parts of methyl methacrylate, 7 parts of n-butyl methacrylate, 4 parts of lauryl methacrylate, 6.5 parts of hydroxyethyl methacrylate, 7 parts of tert-butyl methacrylate, 7 parts of n-butyl methacrylate 8 parts of butyl ester, 0.2 part of acrylic acid, 0.15 part of 1,1-bis(tert-butylperoxy)cyclohexane, 0.4 part of tert-butyl peroxybenzoate, 1.0 part of butyl acetate;

[0030] Additional material 1: 0.1 part of 1,1-bis(tert-butylperoxy)cyclohexane and 1 part of butyl acetate;

[0031] Supplementary material 2: 0.05 part of 1,1-bis(tert-butylperoxy)cyclohexane, 1 part of butyl acetate;

[0032] Thinner: 2 parts of butyl acetate.

[0033] The preparation method of the hydroxy acrylic resin suitable for the heat-refl...

Embodiment 2

[0045] The hydroxy acrylic resin suitable for the heat-reflecting and heat-insulating paint of this embodiment includes the following raw materials in parts by weight:

[0046] Bottom material: 46 parts of butyl acetate;

[0047] Mixed monomer dropwise addition: 12 parts methyl methacrylate, 9 parts n-butyl methacrylate, 4 parts lauryl methacrylate, 8 parts hydroxyethyl methacrylate, 9 parts tert-butyl methacrylate, acrylic acid 8.5 parts of n-butyl ester, 0.25 part of acrylic acid, 0.2 part of 1,1-bis(tert-butylperoxy)cyclohexane, 0.5 part of tert-butyl peroxybenzoate, 1.0 part of butyl acetate;

[0048] Supplementary material 1: 0.12 part of 1,1-bis(tert-butylperoxy)cyclohexane, 1.5 part of butyl acetate;

[0049] Supplement 2: 0.06 part of 1,1-bis(tert-butylperoxy)cyclohexane, 1.5 part of butyl acetate;

[0050] Thinner: 2.5 parts of butyl acetate.

[0051] The preparation method of the hydroxy acrylic resin suitable for the heat-reflecting heat-insulating coating of the...

Embodiment 3

[0063] The hydroxy acrylic resin suitable for the heat-reflecting and heat-insulating paint of this embodiment includes the following raw materials in parts by weight:

[0064] Bottom material: 47 parts of butyl acetate;

[0065] Mixed monomer dropwise addition: 13 parts of methyl methacrylate, 9 parts of n-butyl methacrylate, 5.5 parts of lauryl methacrylate, 8.5 parts of hydroxyethyl methacrylate, 10.5 parts of tert-butyl methacrylate, acrylic acid 7.5 parts of n-butyl ester, 0.4 part of acrylic acid, 0.25 part of 1,1-bis(tert-butylperoxy)cyclohexane, 0.45 part of tert-butyl peroxybenzoate, 1.0 part of butyl acetate;

[0066] Additional material 1: 0.15 part of 1,1-bis(tert-butylperoxy)cyclohexane, 2 parts of butyl acetate;

[0067] Supplementary material 2: 0.1 part of 1,1-bis(tert-butylperoxy)cyclohexane, 2 parts of butyl acetate;

[0068] Thinner: 3 parts of butyl acetate.

[0069] The preparation method of the hydroxy acrylic resin suitable for the heat-reflecting hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com