Building coating and preparation method thereof

A technology of architectural coatings and gelling materials, applied in the field of architectural coatings, can solve the problems of coating performance degradation, short service life, high maintenance cost, etc., achieve high impermeability level, excellent bonding performance, and avoid corrosive gas damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

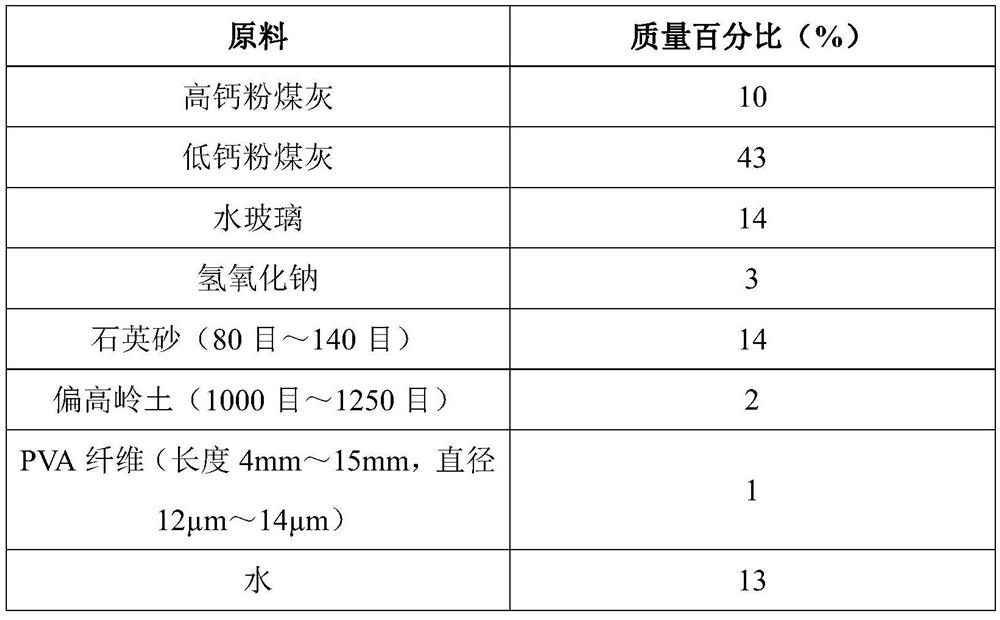

[0043] A kind of architectural coating, its composition is as shown in the following table:

[0044] Table 1 A composition table of architectural coatings

[0045]

[0046] Note: According to the content of CaO in the ash of raw coal after combustion, the fly ash with CaO content > 53% is high calcium fly ash, the fly ash with CaO content 46% ~ 53% is medium calcium fly ash, and the fly ash with CaO content < 46% is low calcium fly ash.

[0047] The preparation method of the above architectural paint comprises the following steps: mixing high-calcium fly ash, low-calcium fly ash, quartz sand and metakaolin, stirring, then adding water glass, sodium hydroxide and water, stirring, and then adding PVA Fibers are stirred to obtain architectural coatings.

Embodiment 2

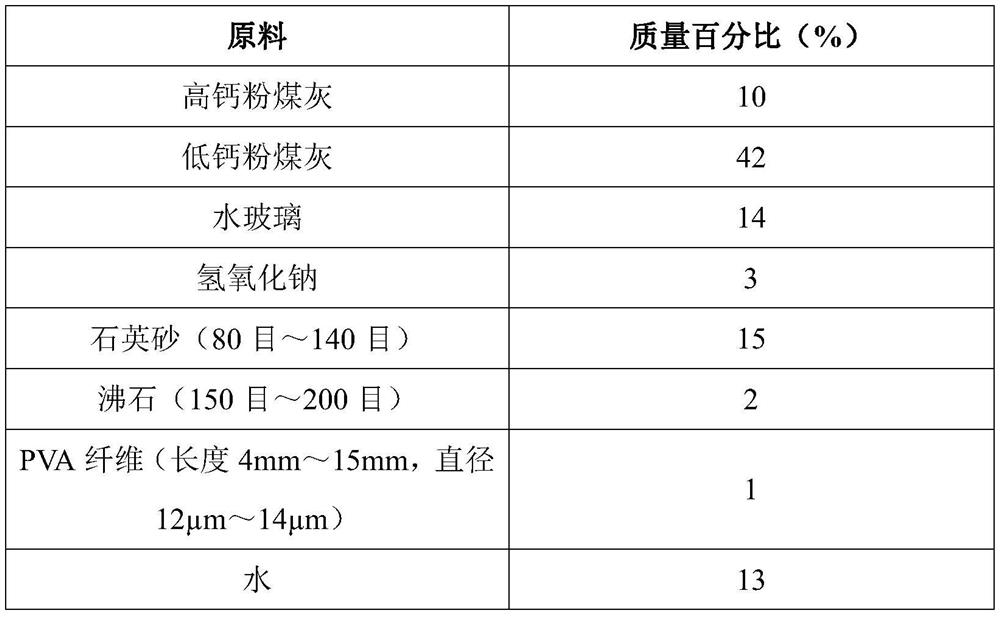

[0049] A kind of architectural coating, its composition is as shown in the following table:

[0050] Table 2 A composition table of architectural coatings

[0051]

[0052] Note: According to the content of CaO in the ash of raw coal after combustion, the fly ash with CaO content > 53% is high calcium fly ash, the fly ash with CaO content 46% ~ 53% is medium calcium fly ash, and the fly ash with CaO content < 46% is low calcium fly ash.

[0053] The preparation method of the above architectural paint comprises the following steps: mixing high-calcium fly ash, low-calcium fly ash, quartz sand and zeolite, stirring, then adding water glass, sodium hydroxide and water, stirring, and then adding PVA fiber , stirred to obtain architectural coatings.

Embodiment 3

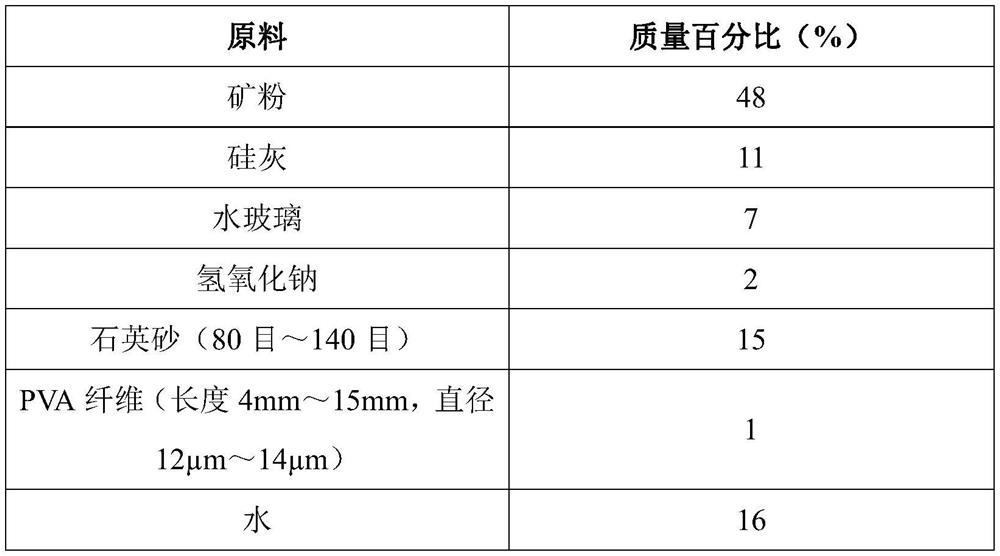

[0055] A kind of architectural coating, its composition is as shown in the following table:

[0056] Table 3 A composition table of architectural coatings

[0057]

[0058] The preparation method of the above-mentioned architectural coating comprises the following steps: mixing mineral powder, silica fume and quartz sand, stirring, adding water glass, sodium hydroxide and water, stirring, adding PVA fiber, and stirring to obtain the architectural coating .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com