Process for hydrogen production and co-production of LNG from raw gas with methanation

A waste gas and methanation technology, applied in hydrogen separation, petroleum industry, gas fuel, etc., can solve the problems of high impurity purification requirements, poor economy, low methane content, etc., to ensure long-term stable operation, reduce investment and energy. consumption, improve economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

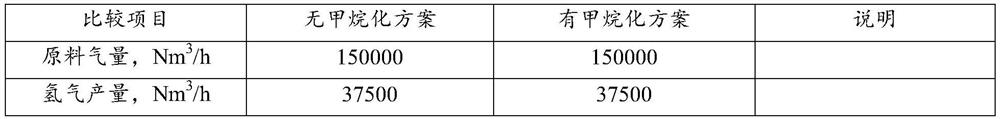

Embodiment 1

[0040] Raw coal gas 60℃, pressure 4kPaG, gas volume 150000Nm 3 / h (dry basis), dry basis composition (V%) nitrogen 44, hydrogen 24, carbon monoxide 12, carbon dioxide 12, methane 6, oxygen 1.0, CnHm1.0, impurity composition is (mg / Nm 3 ): tar 1000, naphthalene 500, ammonia 500, hydrogen sulfide 600, organic sulfur 200, hydrogen cyanide 200, C6 and above hydrocarbons 500.

[0041] In this embodiment, the specific steps of the raw coal gas hydrogen production co-production LNG process are as follows:

[0042] 1. Pretreatment: Raw coal gas is pressurized by the blower to 10kPaG, and then enters the horizontal tube cooler. The upper section of the horizontal tube cooler is cooled to 40°C with circulating cooling water, and the lower section is cooled with 7°C low-temperature circulating water, and the temperature is reduced to 23°C. Then enter the two-stage electric tar catcher, the tar is reduced to 100mg / Nm 3 , naphthalene reduced to 50mg / Nm 3 , the pressure drops to 6kPaG, a...

Embodiment 2

[0055] Raw coal gas 60℃, pressure 4kPaG, gas volume 150000Nm 3 / h (dry basis), dry basis composition (V%) nitrogen 44, hydrogen 24, carbon monoxide 12, carbon dioxide 12, methane 6.0, oxygen 1.0, CnHm1.0, impurity composition is (mg / Nm 3 ): tar 1000, naphthalene 500, ammonia 500, hydrogen sulfide 600, organic sulfur 200, hydrogen cyanide 200, C6 and above hydrocarbons 500.

[0056] In this embodiment, hydrogen users stop production, and all LNG is produced by adjusting the conversion rate of CO and through methanation. Specific steps are as follows:

[0057] 1. Pretreatment: Raw coal gas is pressurized by the blower to 10kPaG, and then enters the horizontal tube cooler. The upper section of the horizontal tube cooler is cooled to 40°C with circulating cooling water, and the lower section is cooled with 7°C low-temperature circulating water, and the temperature is reduced to 23°C. Then enter the two-stage electric tar catcher, the tar is reduced to 100mg / Nm 3 , naphthalene r...

Embodiment 3

[0065] Raw coal gas 60℃, pressure 4kPaG, gas volume 115000Nm 3 / h (dry basis), dry basis composition (V%) nitrogen 44, hydrogen 24, carbon monoxide 12, carbon dioxide 12, methane 6, oxygen 1.0, CnHm1.0, impurity composition is (mg / Nm 3 ): tar 1000, naphthalene 500, ammonia 500, hydrogen sulfide 600, organic sulfur 200, hydrogen cyanide 200, C6 and above hydrocarbons 500.

[0066] In this example, raw coal gas has insufficient raw material gas volume, and in order to ensure hydrogen production, no methanation is carried out. After desulfurization and decarburization, the gas directly enters the PSA unit to extract hydrogen. The specific steps are as follows:

[0067] 1. Pretreatment: Raw coal gas is pressurized by the blower to 10kPaG, and then enters the horizontal tube cooler. The upper section of the horizontal tube cooler is cooled to 40°C with circulating cooling water, and the lower section is cooled with 7°C low-temperature circulating water, and the temperature is redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com