Micro-foaming PVC (polyvinyl chloride) floor without plasticizer and preparation method of micro-foaming PVC floor

A technology of micro-foaming and plasticizer, which is applied in the field of micro-foaming PVC flooring and its preparation, can solve the problems of plasticizer-containing and unstable performance of foaming WPC flooring, etc., achieve easy processing and molding, and ensure stable use dimensions Sexuality and the effect of improving foot comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

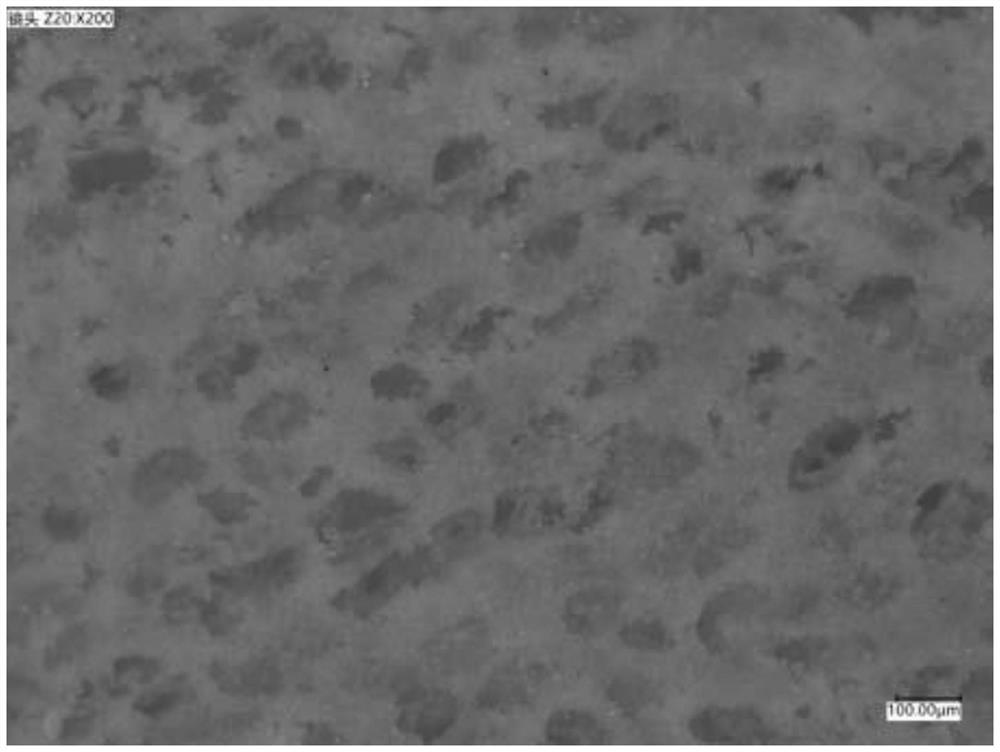

Image

Examples

Embodiment 1

[0041] A kind of plasticizer-free micro-foamed PVC floor, which successively comprises a PVC hard transparent sheet bottom layer, a rigid micro-foamed SPC base material, a PVC printing layer and a PVC hard transparent sheet surface layer from bottom to top; the PVC hard Both the bottom layer of the transparent sheet and the surface layer of the PVC rigid transparent sheet do not contain plasticizers.

[0042] Both the bottom layer of the PVC hard transparent sheet and the surface layer of the PVC hard transparent sheet include the following components (by weight): 100 parts of PVC resin powder, 2 parts of calcium zinc stabilizer, 0.5 part of internal lubricant stearyl alcohol, External lubricant polyethylene wax 0.5 parts, impact modifier MBS 5 parts and gelling accelerator PA-40 0.5 parts.

[0043] The rigid micro-foaming SPC substrate is a stone-plastic micro-foaming substrate.

[0044] The stone-plastic micro-foaming substrate includes the following components (by weight):...

Embodiment 2

[0055] A kind of plasticizer-free micro-foamed PVC floor, which successively comprises a PVC hard transparent sheet bottom layer, a rigid micro-foamed SPC base material, a PVC printing layer and a PVC hard transparent sheet surface layer from bottom to top; the PVC hard Both the bottom layer of the transparent sheet and the surface layer of the PVC rigid transparent sheet do not contain plasticizers.

[0056] Both the bottom layer of the PVC hard transparent sheet and the surface layer of the PVC hard transparent sheet include the following components (by weight): 105 parts of PVC resin powder, 4 parts of calcium zinc stabilizer, 1.5 parts of internal lubricant epoxy soybean oil , 1 part of external lubricant stearic acid, 8 parts of impact modifier ACR and 2 parts of gelling accelerator DL-50.

[0057] The rigid micro-foaming SPC substrate is a stone-plastic micro-foaming substrate.

[0058] The stone-plastic micro-foaming substrate includes the following components (by weig...

Embodiment 3

[0068] A kind of plasticizer-free micro-foamed PVC floor, which successively comprises a PVC hard transparent sheet bottom layer, a rigid micro-foamed SPC base material, a PVC printing layer and a PVC hard transparent sheet surface layer from bottom to top; the PVC hard Both the bottom layer of the transparent sheet and the surface layer of the PVC rigid transparent sheet do not contain plasticizers.

[0069] Both the bottom layer of the PVC hard transparent sheet and the surface layer of the PVC hard transparent sheet include the following components (by weight): 100 parts of PVC resin powder, 2 parts of calcium zinc stabilizer, 0.5 part of internal lubricant stearyl alcohol, External lubricant polyethylene wax 0.5 parts, impact modifier MBS 5 parts and gelling accelerator PA-40 0.5 parts.

[0070] The rigid micro-foamed SPC substrate is an expandable microsphere micro-foamed substrate.

[0071] The expandable microsphere microfoaming substrate comprises the following compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com