Trimming block for inner hole grinding clamping jaw and application method of trimming block

A technology of dressing blocks and jaws, applied in the field of precision parts processing, can solve problems such as changes in cutting force, insufficient machining allowance, and scrapped parts, etc., to meet the requirements of grinding processing, to be economical and reliable in dressing, and to ensure reliable positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] The present invention provides a trimming block for inner hole grinding jaws and a method for using the same. The specific steps are as follows:

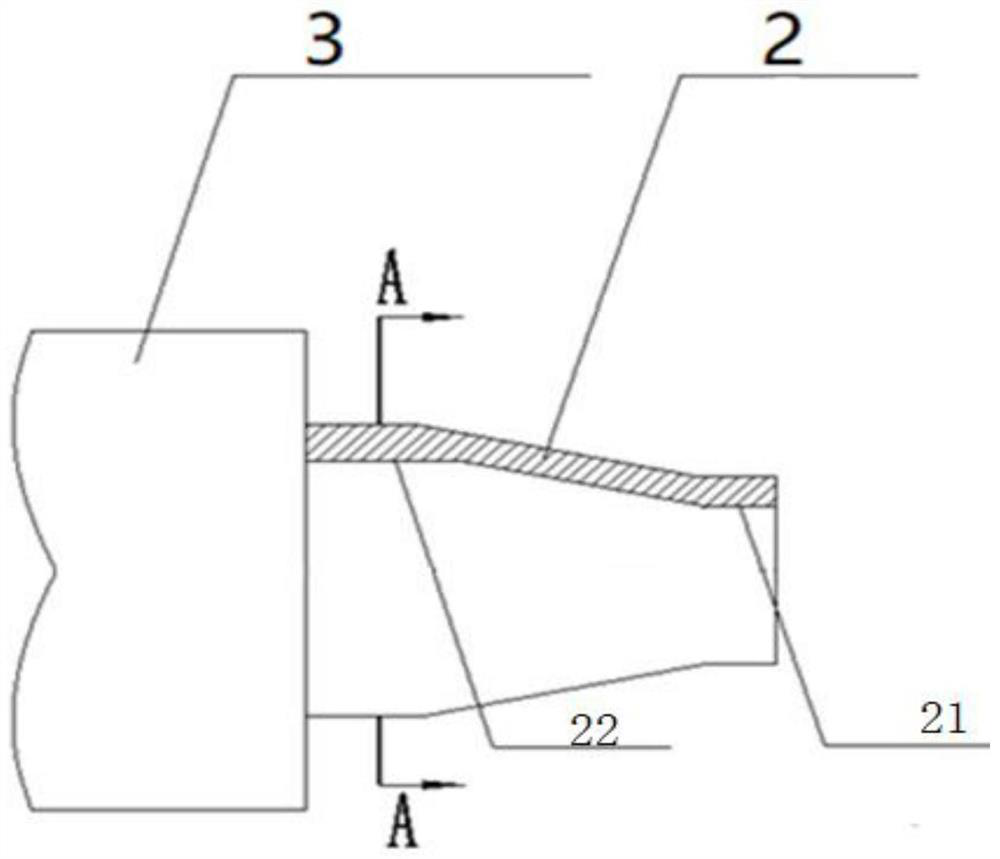

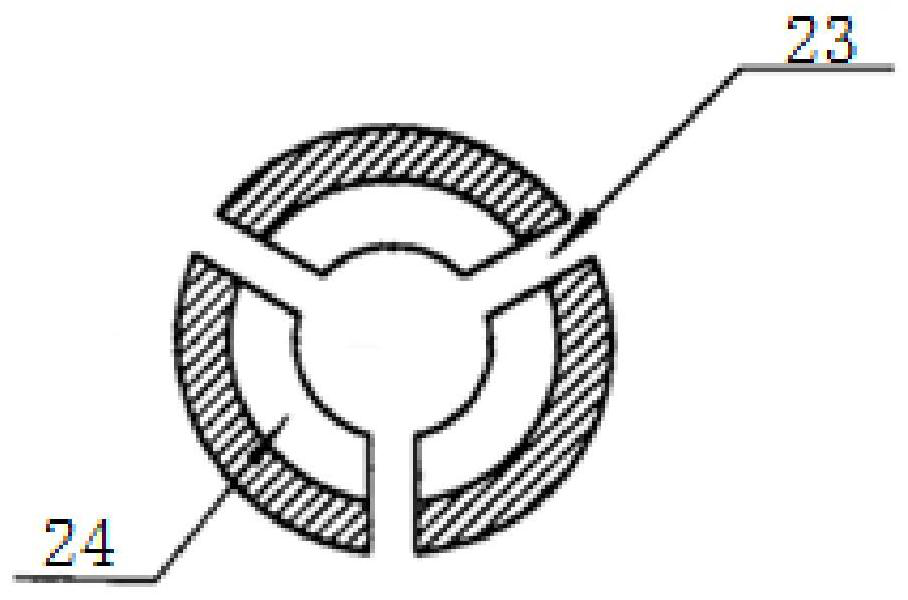

[0025] Such as figure 1 and figure 2 As shown, the precision jaw 2 includes a jaw clamping part 21, an inner side 22 of the jaw, and a jaw wrapping jaw 24. There are gaps between adjacent jaw wrapping jaws 24, and the inner side 22 of the precision jaw 2 is connected with Pneumatic Chuck3.

[0026] (1) Measuring the structural dimensions of the jaws: measuring the size of the inside 22 of the jaws, the length of the precision jaws 2 , the size of the clamping portion 21 of the jaws, and the width between the jaws 24 of each jaw.

[0027] (2) Design and process trimming block:

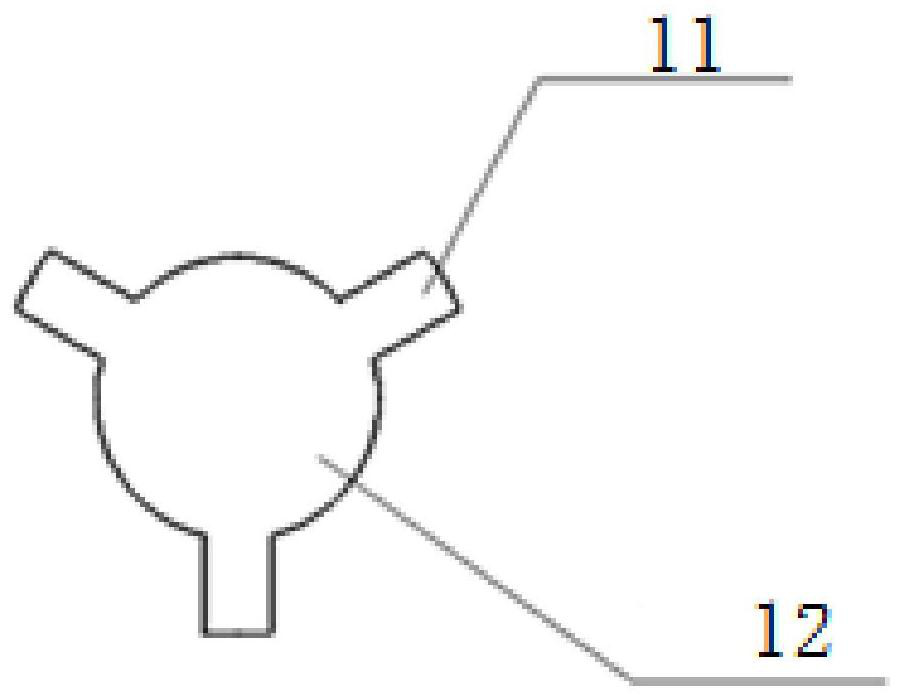

[0028] Such as image 3 As shown, the trimming block 1 includes a cylinder 12 and a plurality of bosses 11 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com