Fixing device suitable for grinding of multi-size optical fiber bundling heads

A technology of fixing device and cluster head, which is used in grinding machines, grinding workpiece supports, grinding/polishing equipment, etc., can solve the problems of inability to grind the cluster head at the same time, reduce the grinding efficiency, and be difficult to clamp, and achieve high disassembly and assembly efficiency. , to meet the grinding requirements, to eliminate the effect of hard impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

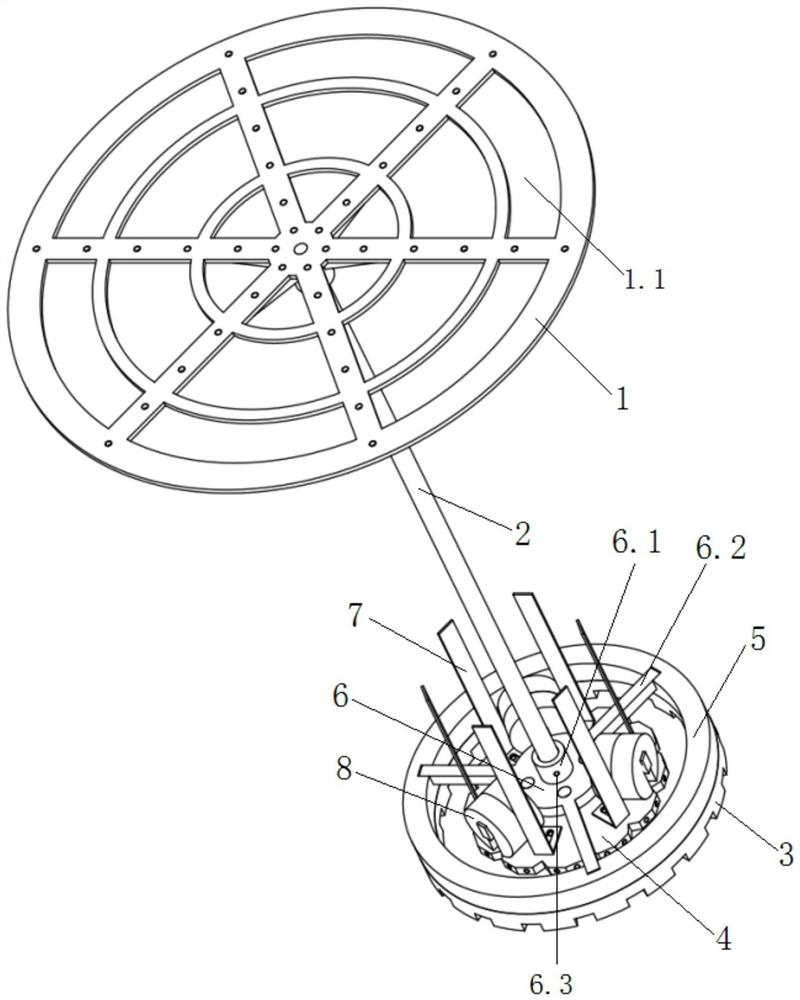

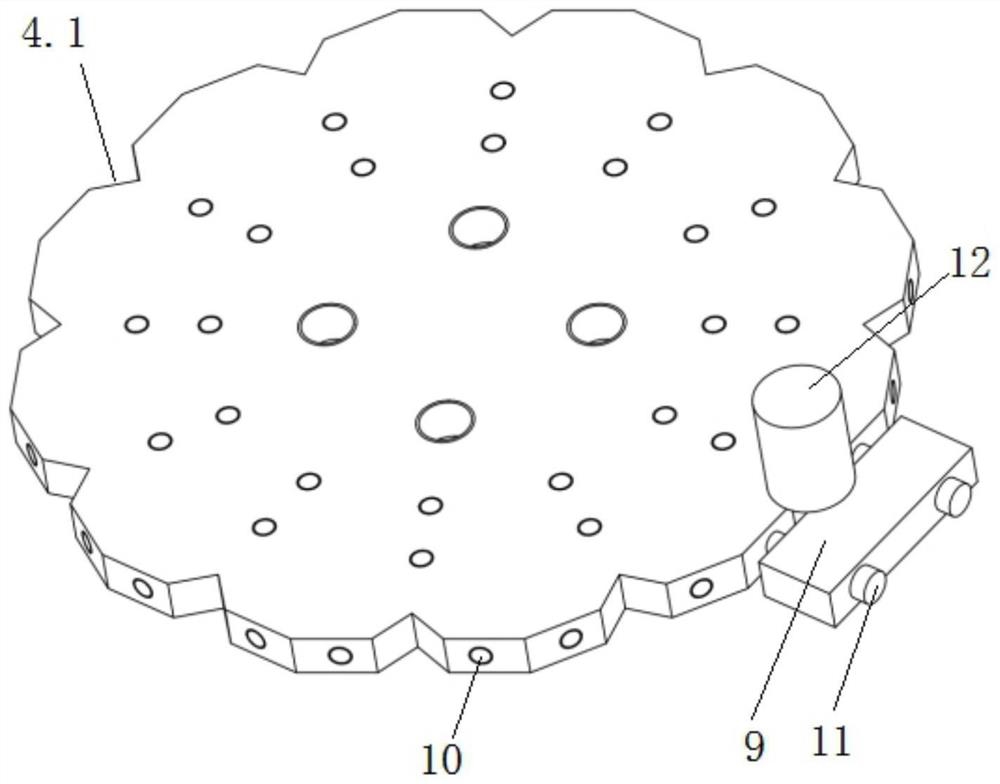

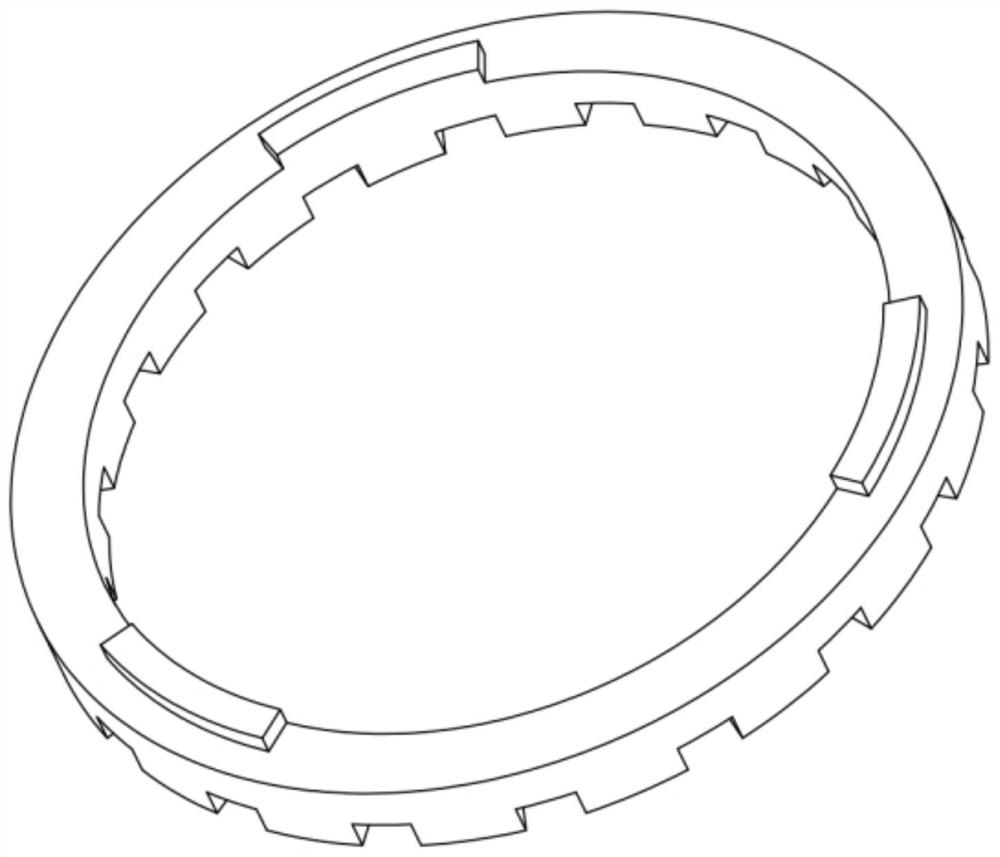

[0019] Such as figure 1 As shown, a fixing device suitable for grinding multi-size optical fiber bundle heads in this embodiment includes an upper grinding ring 5 and a lower grinding ring 3, and the upper grinding ring 5 and the lower grinding ring 3 are quickly inserted through 3 sets of wedge-shaped sub-female The structures are combined, and the upper grinding ring 5 and the lower grinding ring 3 form a circular cavity inside. Three limit grooves are provided in the inner ring of the upper grinding ring 5. The tripod fixing frame 6 is arranged in the upper grinding ring 5 and the three legs 6.2 of the tripod fixing frame 6 are respectively supported in the corresponding limiting grooves. Support and limit the fixed frame. The top of the tripod mount 6 is provided with a synchronous disk 1, and the center of the bottom of the synchronous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com