Clamping device for laser cutting machine

A laser cutting machine and clamping device technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as unreasonable use of time, reduced processing speed and efficiency, cumbersome operation, etc., to prevent harm to operators The effect of health, reduction of unqualified rate, and rational use of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the specific embodiments and the accompanying drawings. It should be understood that these descriptions are exemplary only and are not intended to limit the scope of the invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concepts of the present invention.

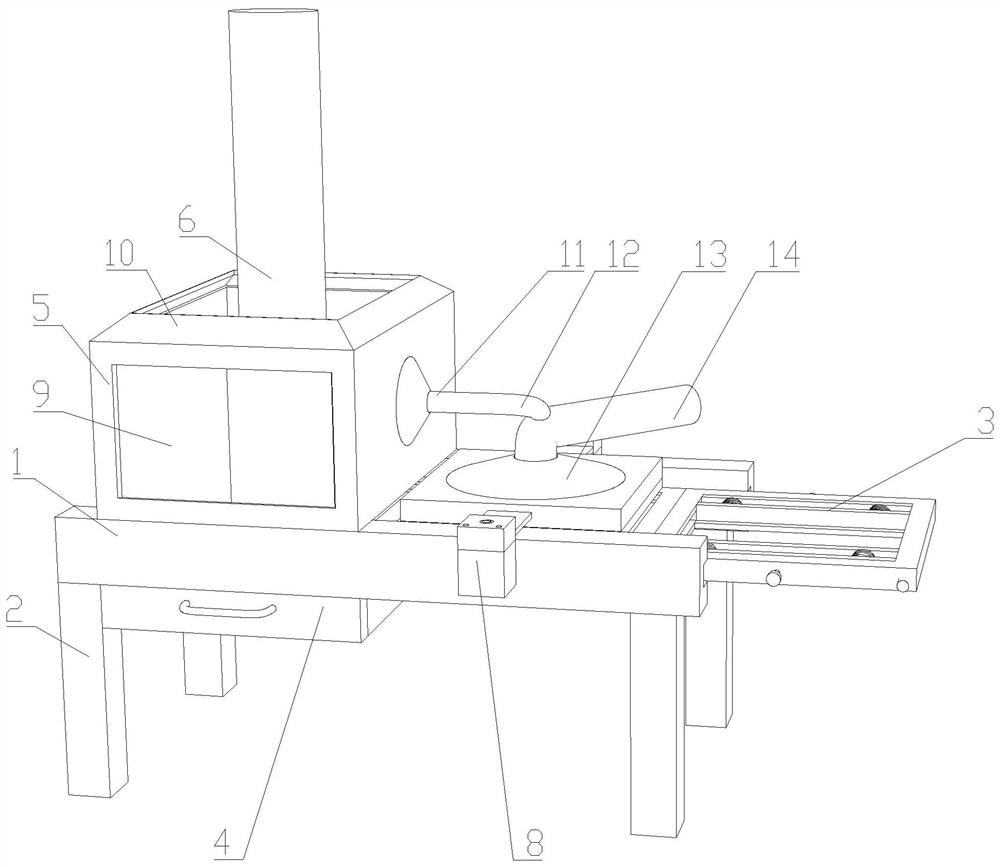

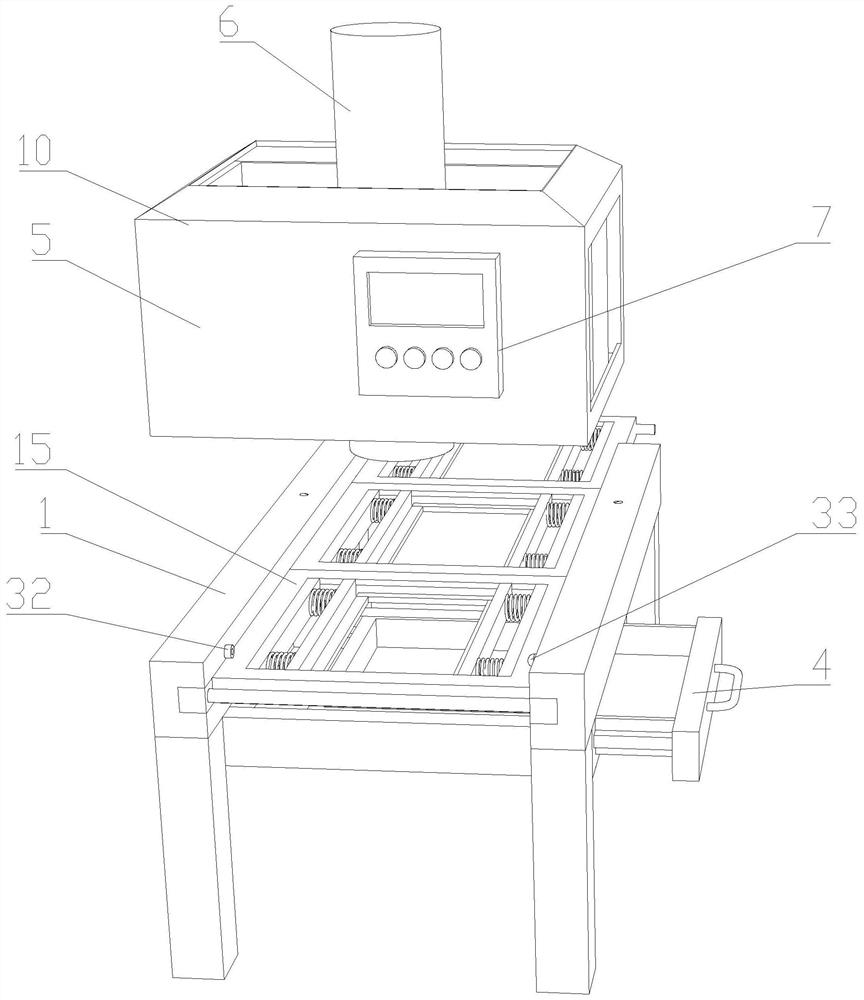

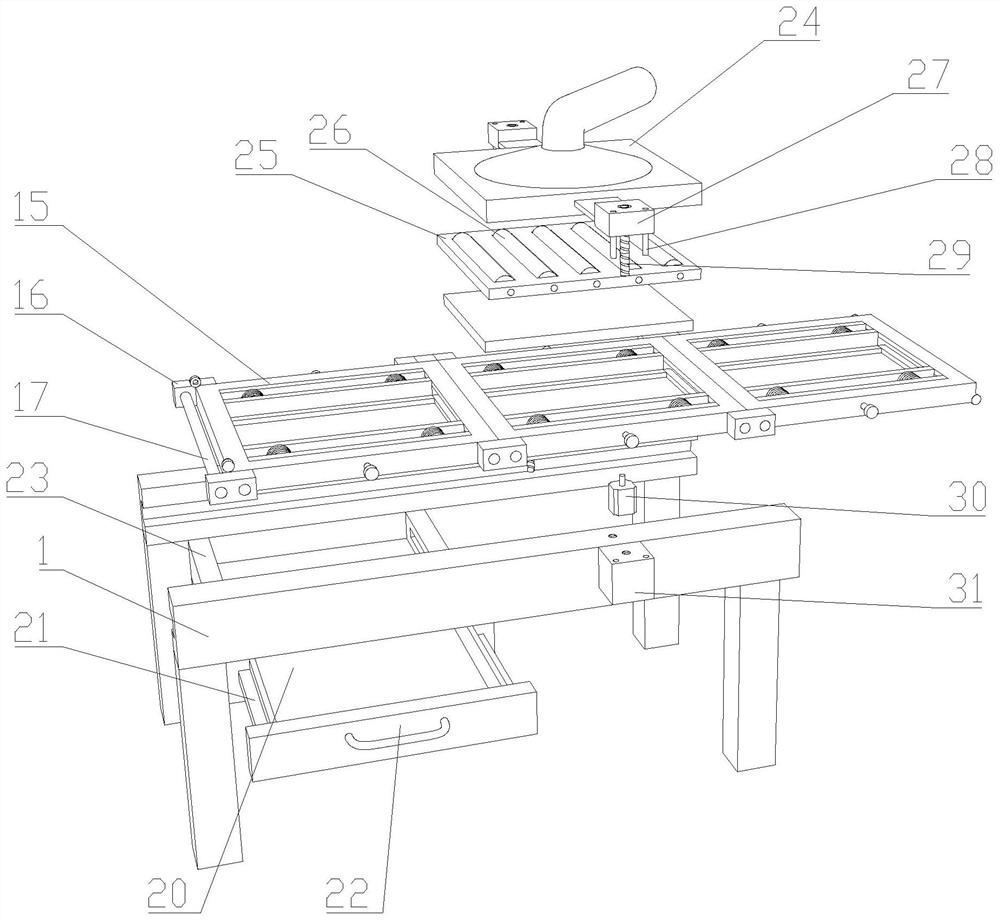

[0030] like Figure 1-5 As shown, a clamping device for a laser cutting machine proposed by the present invention includes a guide rail 1, a supporting foot 2, a transport device 3, a storage device 4, a cutting box 5, a cutting machine 6, an adjustment component 8, and a smoke shield 10. , smoking pipe 11, first trachea 12, receiver 32 and transmitter 33;

[0031] The guide rail 1 is set on the worktable through the supporting feet 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com