Heavy metal contaminated soil remediation agent and remediation method

A technology of polluted soil and remediation agent, which is applied in the field of soil remediation and can solve problems such as perishable, invalid, and poor self-stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

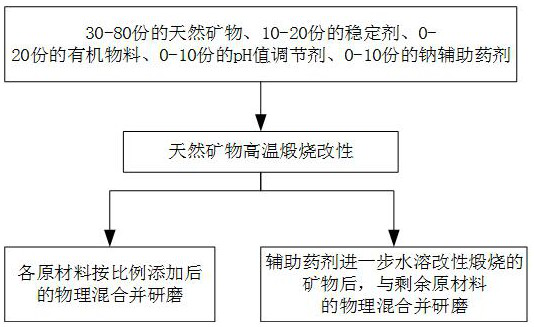

Method used

Image

Examples

Embodiment 1

[0060] 1. Preparation of restoration agent

[0061] (1) Place the natural sepiolite mineral in a muffle furnace for calcination at 700°C for 4 hours, and grind the mineral after cooling to keep it in powder form.

[0062] (2) In terms of mass fraction, take 60 parts of the above-mentioned modified sepiolite, 20 parts of calcium dihydrogen phosphate, 10 parts of biochar, 5 parts of calcium oxide, and 5 parts of sodium carbonate, mix them physically and uniformly, and grind them through a 200-mesh sieve Made into a targeted fix.

[0063] 2. The use of restoratives

[0064] Take 2.5g of restoration agent and add it to 500g of cadmium-contaminated soil in a certain farmland (0.5% addition ratio), keep 30% moisture content, and carry out maintenance.

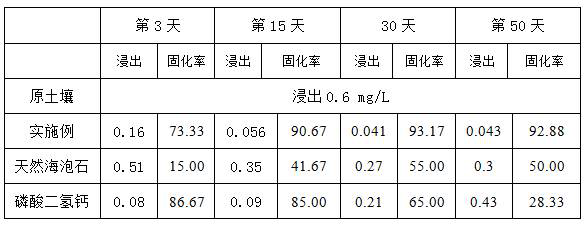

[0065] 3. Comparative example

[0066] Add 2.5g of natural sepiolite and calcium dihydrogen phosphate into 500g of cadmium-contaminated soil of the farmland respectively, and maintain 30% moisture content for maintenance.

[0067...

Embodiment 2

[0074] 1. Preparation of restoration agent

[0075] (1) Place the natural attapulgite powder in a muffle furnace and keep it calcined at 600°C for 3 hours. After cooling, grind the mineral to keep it in powder form.

[0076] (2) In terms of mass fraction, take 70 parts of the above-mentioned modified attapulgite powder, 10 parts of potassium dihydrogen phosphate, and 10 parts of humic acid, mix them physically and uniformly, and grind them through a 200-mesh sieve to make the target restoration agent.

[0077] 2. The use of restoratives

[0078] Take 15g of restoration agent and add it to 500g of copper-contaminated soil in a polluted site (3% addition ratio), keep 30% moisture content, and carry out maintenance.

[0079] 3. Comparative example

[0080] Take natural attapulgite powder and 15g of potassium dihydrogen phosphate respectively and add it to 500g of copper-contaminated soil of the polluted site to maintain a moisture content of 30% for maintenance.

[0081] 4. Im...

Embodiment 3

[0087] 1. Preparation of restoration agent

[0088] (1) Put the natural kaolin powder in a muffle furnace for calcination at 650°C for 6 hours, and grind the mineral after cooling to keep the powder.

[0089] (2) In terms of mass fraction, take 70 parts of the above-mentioned modified attapulgite powder, 10 parts of potassium dihydrogen phosphate, 10 parts of biochar, and 10 parts of calcium oxide for physical uniform mixing, and grind through a 200-mesh sieve to make the target restoration agent.

[0090] 2. The use of restoratives

[0091] Take 25g of restoration agent and add it to 500g copper, arsenic, zinc, lead contaminated soil of a polluted site (5% addition ratio), keep 40% moisture content, and maintain for 10 days.

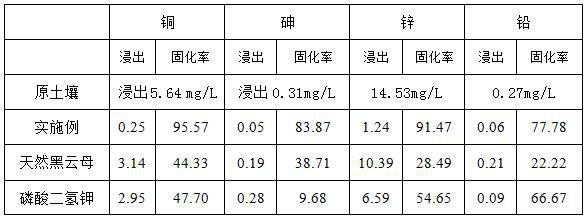

[0092] 3. Comparative example

[0093] Take natural biotite powder and 25g of potassium dihydrogen phosphate and add them to 500g of copper, arsenic, zinc, and lead-contaminated soil of the polluted site, keep 40% moisture content, and maintain for 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com