Preparation method of monatomic catalyst for activating sulfite to degrade pollutants

A technology for activating sulfite and pollutants, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, water pollutants, etc., to achieve remarkable catalytic effect, simple and effective synthesis method, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a single-atom catalyst for activating sulfite to degrade pollutants, comprising the steps of:

[0030] (1) Pretreatment of raw materials: drying sodium lignosulfonate at a low temperature of 55°C for 2 hours for later use, then mixing sodium lignosulfonate and ferric nitrate in a ratio of 5:4;

[0031] (2) Mechanical ball milling: Add the above mixture into a mechanically activated solid-phase reactor, and carry out ball milling reaction at a speed of 400r / min and a constant temperature water bath temperature of 50°C. After 20min, stop the ball milling to obtain a dark brown mixture;

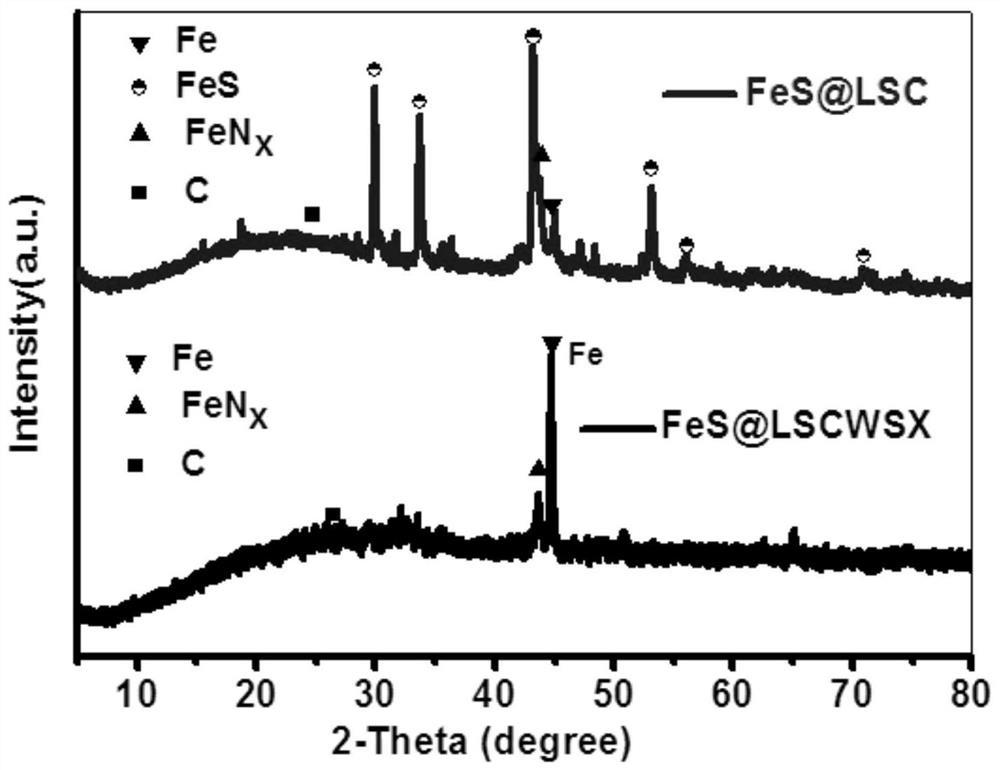

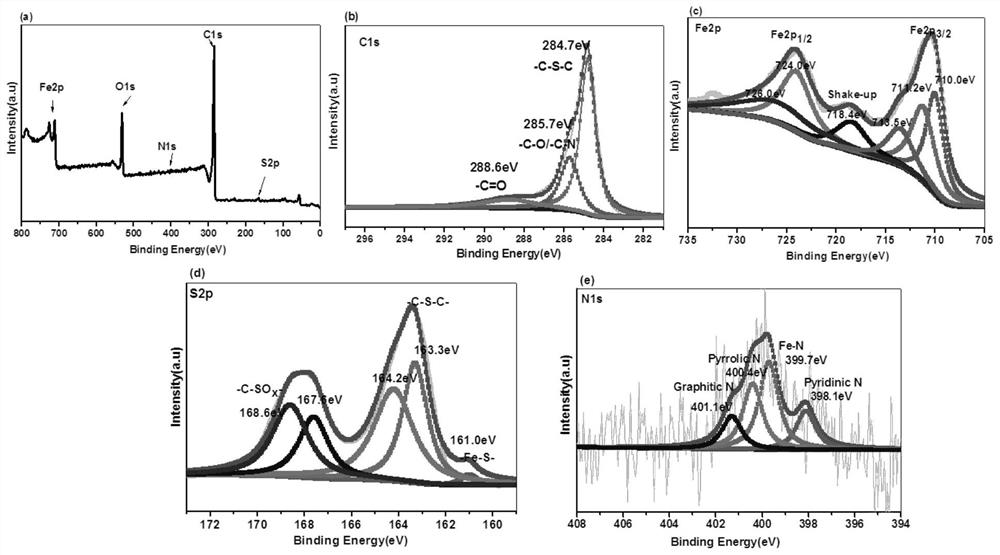

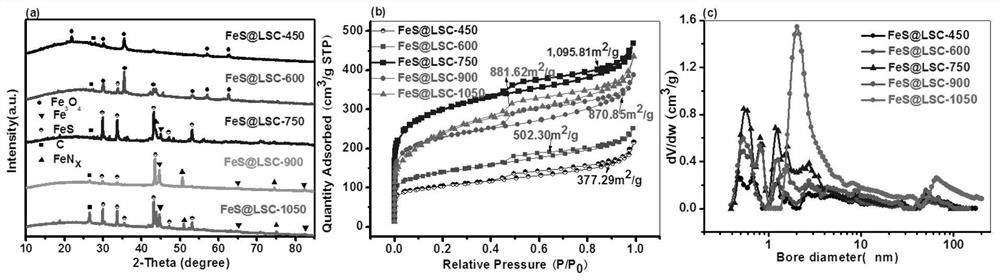

[0032] (3) High-temperature carbonization: Add the mixture in step (2) to a high-temperature tube furnace, raise the temperature to 750°C at a heating rate of 5°C / min, keep the temperature at 750°C for 2 hours, and then cool to 10°C / min. At room temperature, a black carbonized sample was obtained;

[0033] (4) Pickling: After grinding the carbonized sample in step ...

Embodiment 2

[0041] A method for preparing a single-atom catalyst for activating sulfite to degrade pollutants, comprising the steps of:

[0042] (1) Pretreatment of raw materials: drying sodium lignosulfonate at a low temperature of 55°C for 2 hours for later use, then mixing sodium lignosulfonate and ferric nitrate in a ratio of 5:4;

[0043] (2) Mechanical ball milling: Add the above mixture into a mechanically activated solid-phase reactor, and carry out ball milling reaction at a speed of 400r / min and a constant temperature water bath temperature of 50°C. After 20min, stop the ball milling to obtain a dark brown mixture;

[0044] (3) High-temperature carbonization: Add the mixture in step (2) to a high-temperature tube furnace, raise the temperature to 450°C at a heating rate of 5°C / min, keep the temperature at 450°C for 2 hours, and then cool to 10°C / min at a cooling rate of At room temperature, a black carbonized sample was obtained;

Embodiment 3

[0049] A method for preparing a single-atom catalyst for activating sulfite to degrade pollutants, comprising the steps of:

[0050] (1) Pretreatment of raw materials: drying sodium lignosulfonate at a low temperature of 55°C for 2 hours for later use, then mixing sodium lignosulfonate and ferric nitrate in a ratio of 5:4;

[0051] (2) Mechanical ball milling: Add the above mixture into a mechanically activated solid-phase reactor, and carry out ball milling reaction at a speed of 400r / min and a constant temperature water bath temperature of 50°C. After 20min, stop the ball milling to obtain a dark brown mixture;

[0052] (3) High-temperature carbonization: Add the mixture in step (2) to a high-temperature tube furnace, raise the temperature to 600°C at a heating rate of 5°C / min, keep the temperature at 600°C for 2 hours, and then cool it down to 10°C / min. At room temperature, a black carbonized sample was obtained;

[0053] (4) Pickling: After grinding the carbonized sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com