Low-viscosity high-efficiency emulsion type defoaming agent for offshore oilfield and preparation method thereof

An emulsion-type defoamer, offshore oilfield technology, applied in separation methods, chemical instruments and methods, liquid degassing, etc., can solve problems such as poor performance, difficult on-site filling, high viscosity, etc., and achieve good spreadability and diffusivity , Good emulsification and dispersion effect, good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A low-viscosity and high-efficiency emulsion-type defoamer for offshore oilfields of the present invention is prepared from a mass fraction of 5wt% defoamer main agent, 1wt% co-emulsifier, 0.01wt% stabilizer and 93.99wt% dispersant Wherein, the antifoaming main agent is the polyether silicone oil B of the active silicone paste A of 10 mass parts, 80 mass parts, the propylene glycol polyether C of 10 mass parts, accounting for the mass fraction of the antifoaming main agent is 0.01% Prepared under the catalysis of solid complex platinum.

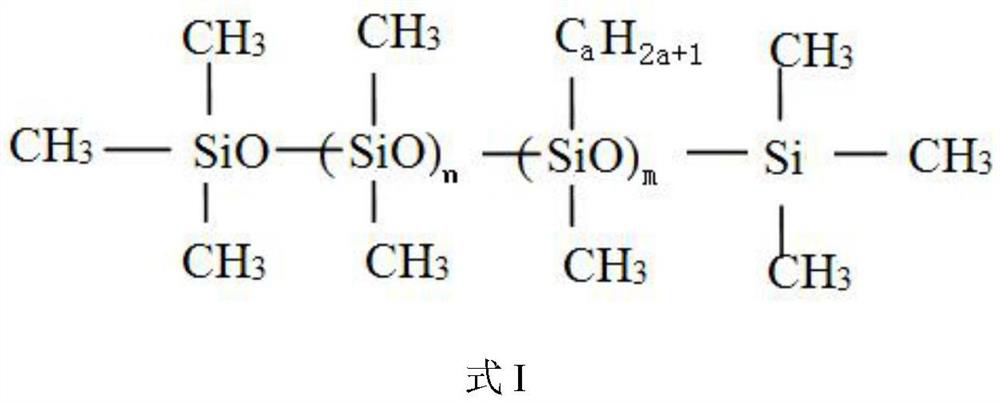

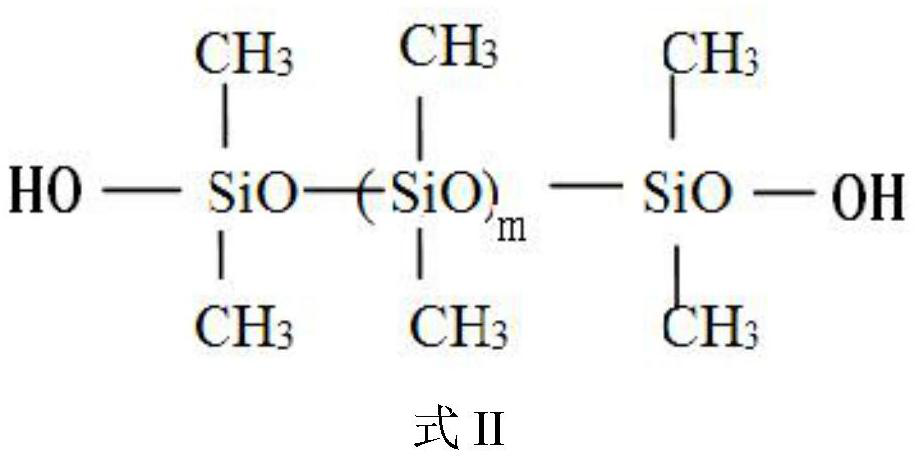

[0037] The active silicone paste A consists of 30 parts by mass of mixed structure long-chain alkyl polydimethylsiloxane, 25 parts by mass of high molecular weight polydimethylsiloxanol and 30 parts by mass of polyether alkyl Modified silicone oil is prepared by reacting 15 parts by mass of hydrophilic fumed silica at high temperature.

[0038] The preparation method of the low-viscosity high-efficiency emulsion type defoamer for the ...

Embodiment 2

[0043] A low-viscosity high-efficiency emulsion-type defoamer for offshore oilfields of the present invention is prepared from a mass fraction of 10wt% defoamer main agent, 2wt% co-emulsifier, 0.02wt% stabilizer and 87.98wt% dispersant; Wherein, the antifoaming main agent is 30 mass parts of active silicone paste A, 40 mass parts of polyether silicone oil B, 30 mass parts of propylene glycol polyether C, and the mass fraction of the antifoaming main agent is 0.02% solid Prepared under the catalysis of complex platinum.

[0044] The active silicone paste A consists of 40 parts by mass of mixed structure long-chain alkyl polydimethylsiloxane, 40 parts by mass of high molecular weight polydimethylsiloxanol and 10 parts by mass of polyether alkyl Modified silicone oil is prepared by reacting 10 parts by mass of hydrophilic fumed silica at high temperature.

[0045] The preparation method of the low-viscosity high-efficiency emulsion type defoamer for the above-mentioned offshore ...

Embodiment 3

[0050] A low-viscosity and high-efficiency emulsion-type defoamer for offshore oil fields of the present invention is prepared from a mass fraction of 8wt% defoamer main agent, 1.5wt% co-emulsifier, 0.015wt% stabilizer and 90.485wt% dispersant Wherein, described defoaming main agent is the polyether silicone oil B of the active silicone paste A of 20 mass parts, 60 mass parts, the propylene glycol polyether C of 20 mass parts, accounting for the mass fraction of defoaming main agent is 0.05% Prepared under the catalysis of solid complex platinum.

[0051] The active silicone paste A consists of 32 parts by mass of mixed structure long-chain alkyl polydimethylsiloxane, 30 parts by mass of high molecular weight polydimethylsiloxanol and 30 parts by mass of polyether alkyl Modified silicone oil, prepared by reacting 8 parts by mass of hydrophilic fumed silica at high temperature.

[0052] The preparation method of the low-viscosity high-efficiency emulsion type defoamer for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com