Implementation method of high-gain omnidirectional biconical antenna array

A technology of biconical antenna and implementation method, which is applied in the direction of manufacturing antenna array devices, antenna arrays, antennas, etc., and can solve problems such as deterioration of out-of-roundness, affecting the practical application of antennas, and affecting the omnidirectionality of the azimuth plane pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

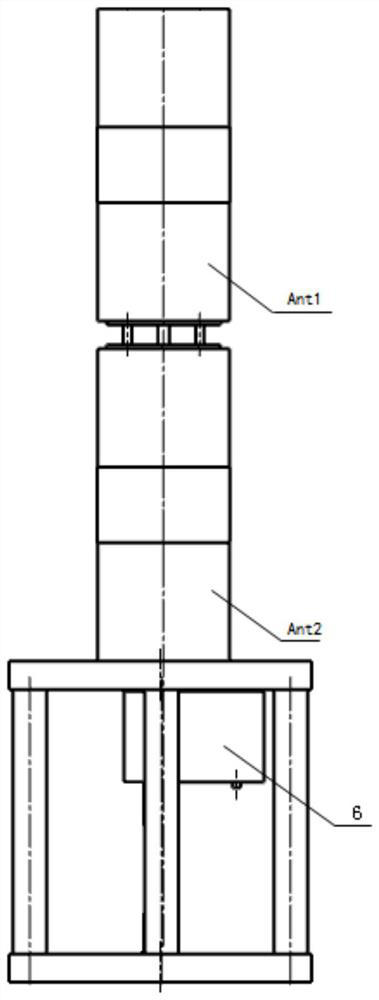

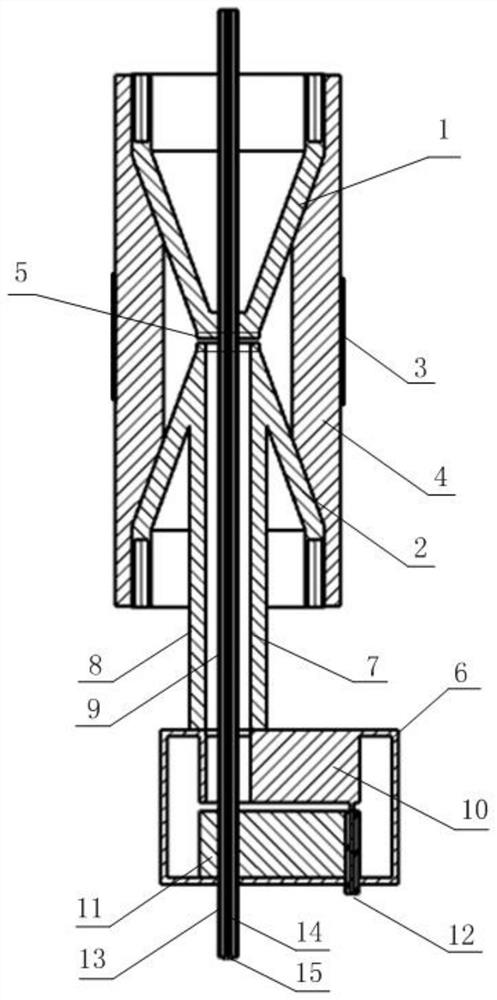

[0019] Embodiment: The two-unit high-gain omnidirectional biconical antenna array designed by the method of the present invention is as attached figure 1 As shown, the main steps are as follows:

[0020] 1. Design the antenna unit according to the bandwidth: the design of the biconical antenna unit belongs to the public technology and will not be described again. The height H2 and the radius of the cylindrical step at the top of the cylindrically loaded biconical antenna cone are adjusted according to the VSWR in the band; the upper cone 1 and lower cone 2. The top diameters are Φ1 and Φ2. The size of the through hole is determined according to the size of the feed coaxial line used for the position of the unit in the array.

[0021] 2. Nested feed coaxial cable design: Nested coaxial cable means that the feed coaxial cable of the upper unit passes through the fed coaxial cable of the lower unit, and its outer conductor serves as the fed coaxial cable of the lower unit The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com