Method and device for evaluating urea crystallization risk based on transient working condition

A technology of transient working conditions and crystallization, which is applied to the electronic control of muffler devices, exhaust devices, and exhaust treatment devices, etc., and can solve problems such as increased fuel consumption of the vehicle, high crystallization of urea, and decreased conversion efficiency of post-treatment NOx. Achieve the effect of high reliability and wide versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

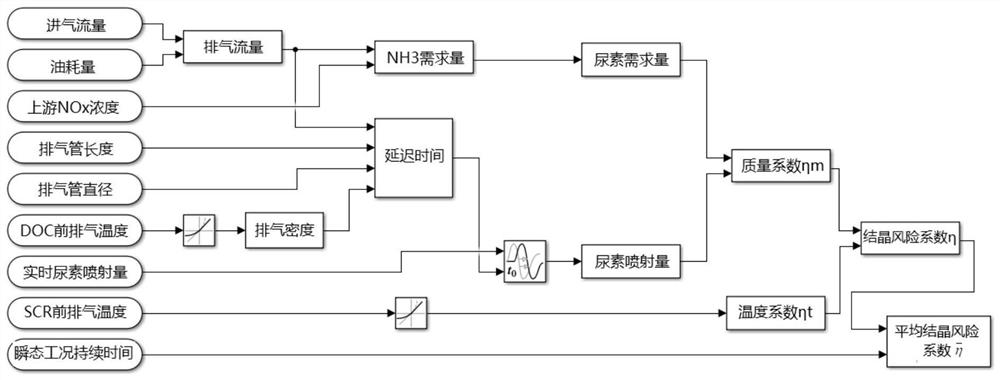

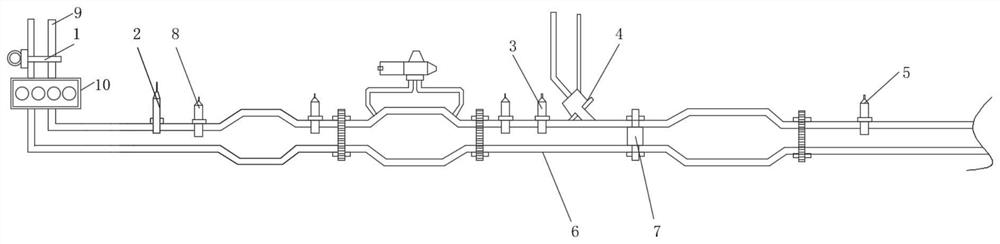

[0015] see Figure 1~2 , in the embodiment of the present invention, a method for evaluating the risk of urea crystallization based on transient working conditions, the evaluation method uses the two most important coefficients affecting urea crystallization, namely the quality risk coefficient and the temperature risk coefficient, from the evaluation of urea injection volume Determine the quality risk coefficient ηm from the angle of temperature, determine the temperature risk coefficient ηt from the angle of temperature, the urea crystallization risk coefficient η and the average crystallization risk coefficient Calculation method, crystallization risk coefficient η is calculated according to mass coefficient ηm and temperature coefficient ηt. It can be the product of the two, or the weighted sum of the two, the form is not limited, and the average crystallization risk coefficient It is obtained by taking the average value of the crystallization risk coefficient η integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com